Device for accurately bending printed circuit board

A printed circuit board and bending technology, which is applied in the field of devices for precise bending of printed circuit boards, can solve problems such as the inability to accurately control the degree of substrate bending and the inability to accurately find the substrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

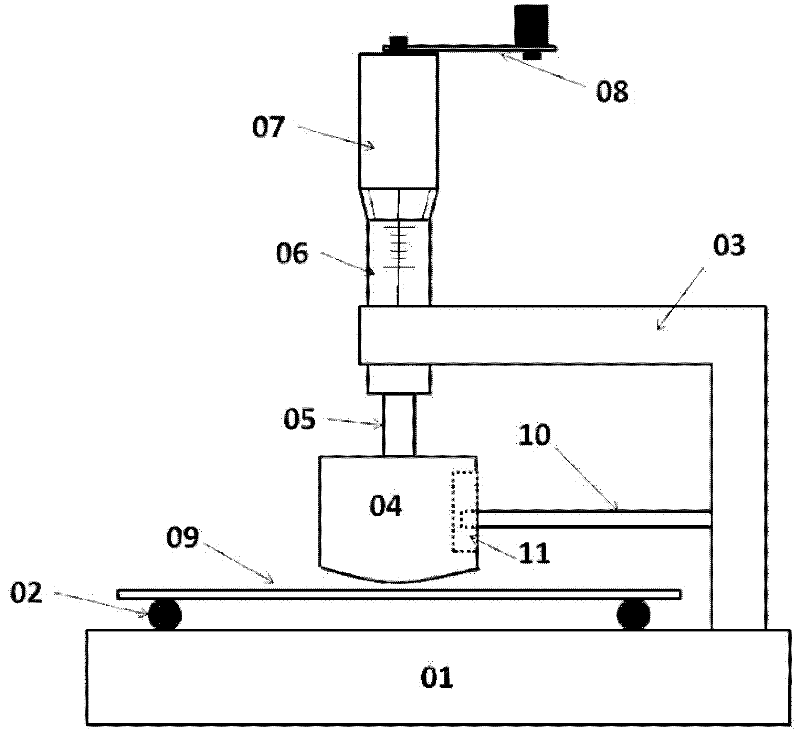

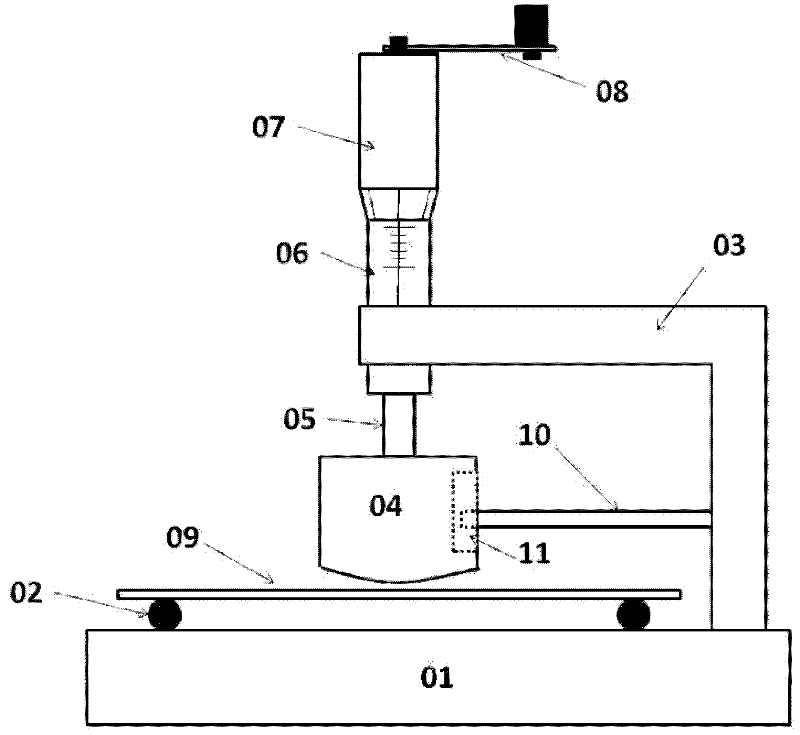

[0022] According to an embodiment of the present invention, there is provided a device for accurately bending a printed circuit board, including:

[0023] Base 01;

[0024] The two gaskets 02 on the base 01, the gasket 02 is cylindrical, and the two cylindrical gaskets are spaced apart and placed in parallel to carry the printed circuit board 09;

[0025] The micrometer includes a rotating part 07, a fixed part 06, and a shaft part 05 connected to the rotating part 07;

[0026] The fixed arm 03 is fixed to the base 01 and is used to fix the fixed part 06 of the micrometer. The fixed arm has a pillar 10 extending laterally from the fixed arm;

[0027] Rocker 08, rotatably fixed to the rotating part 07 of the micrometer;

[0028] The pressing block 04 is rotatably fixed to the shaft 05 of the micrometer. The pressing block has a longitudinal elongated groove 11 on the side close to the fixed arm 03, and one end of the pillar 10 extending laterally from the fixed arm extends into the concav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com