On-line detection production line

A production line and detection platform technology, which is applied in the direction of optical testing for defects/defects, can solve the problems of not being able to meet the needs of small and medium-sized enterprises, the large size of the detection production line, and the difficulty of affording the detection production line, so as to achieve high accuracy and reduce the labor intensity of workers , easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

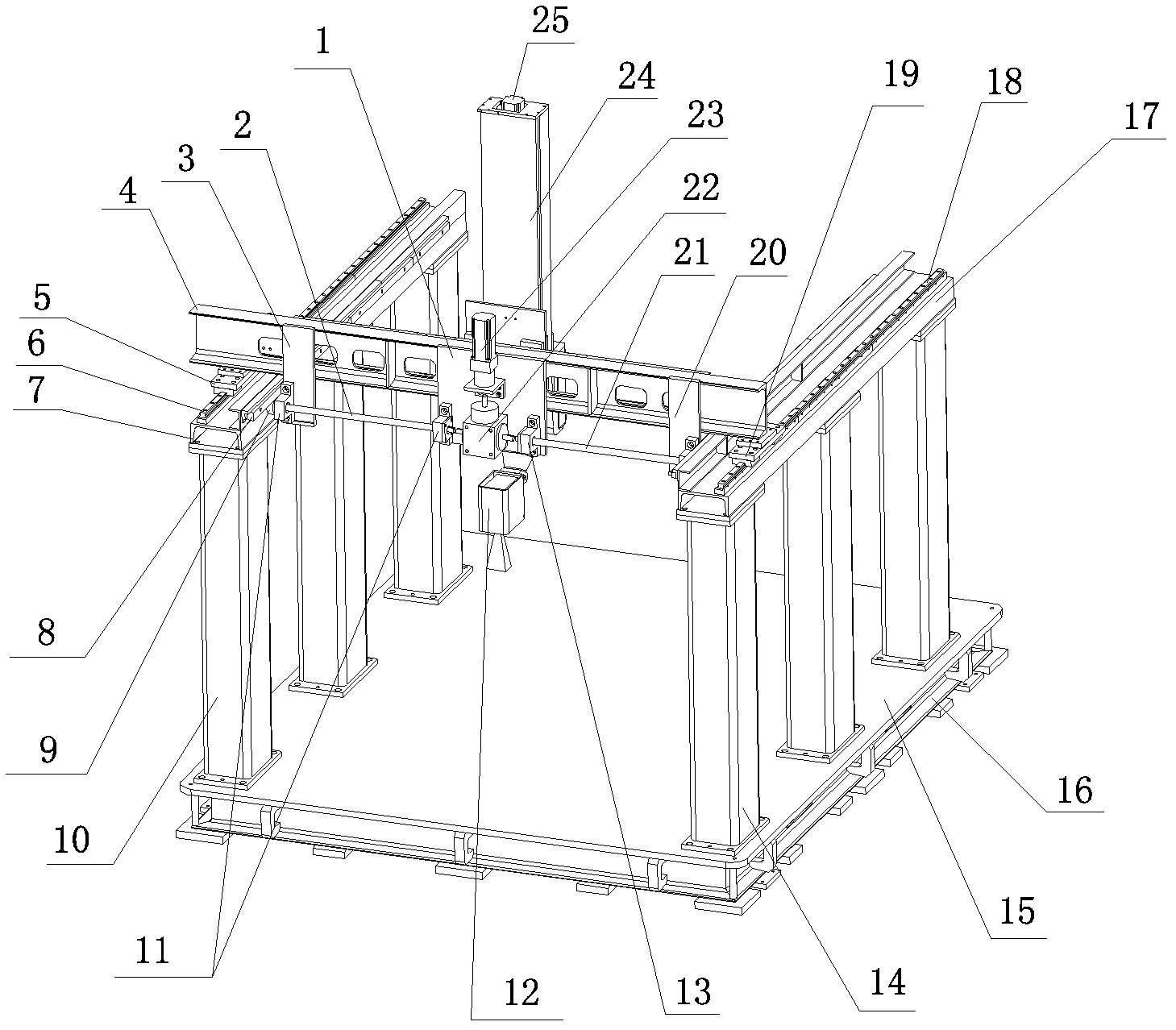

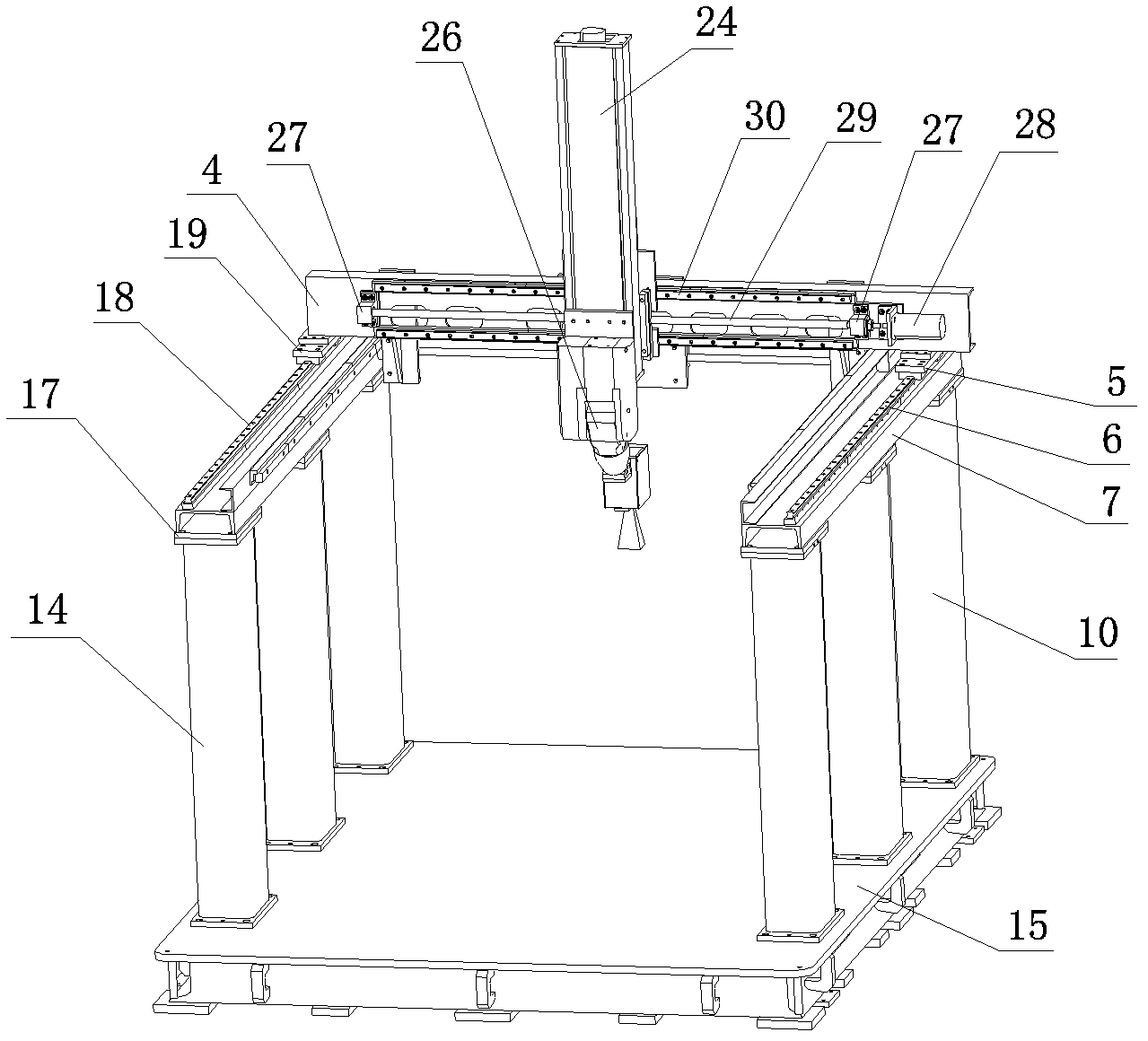

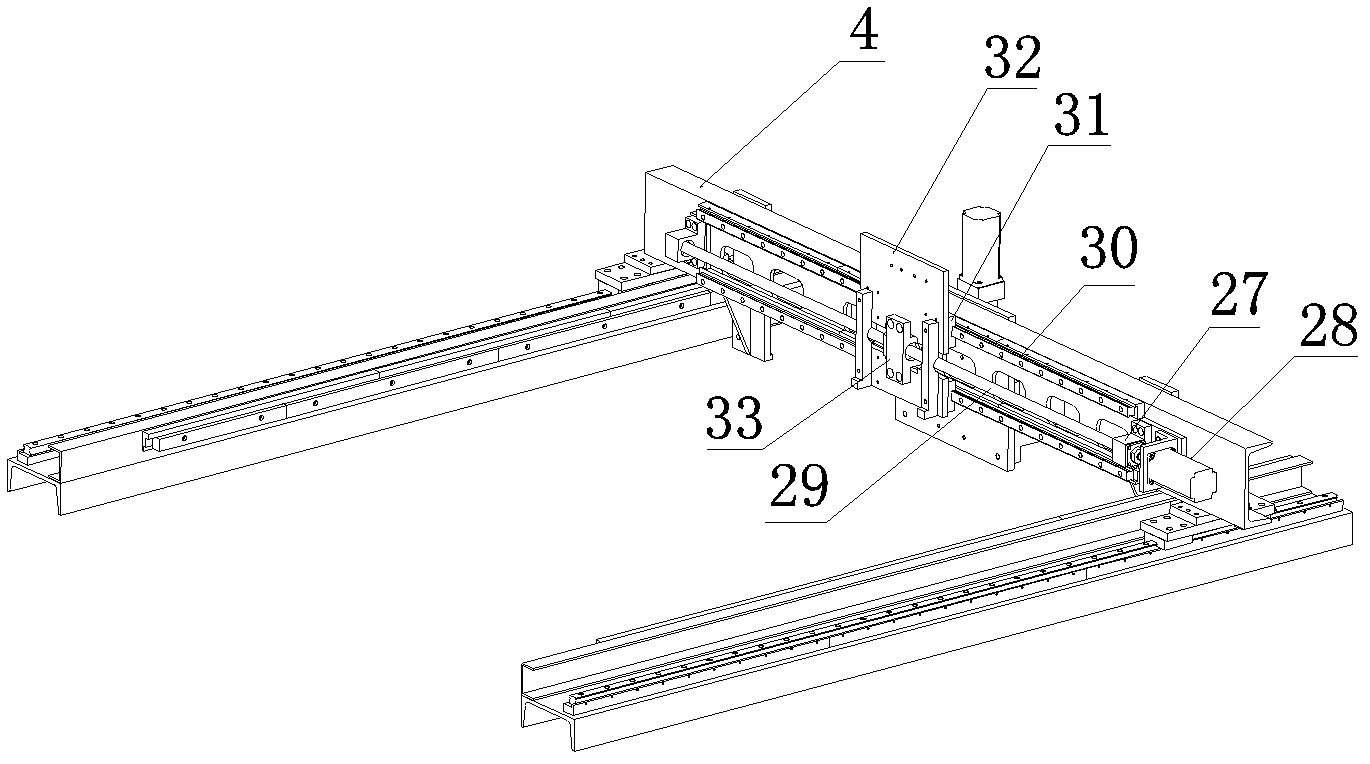

[0026] like Figure 1 to Figure 6 As shown, the online detection production line of the present invention includes a detection platform 15 for placing workpieces to be detected, two rows of support frames 10, 14 respectively arranged on both sides of the detection platform 15, and two rows of support frames 10 respectively arranged on both sides of the detection platform 15. , 14 The top of the support beam I7 and the support beam II17 are parallel to each other, the support beam I7 is fixedly connected with the slide rail I6, the slide rail I6 is connected with the slider I5 that can slide relative to the slide rail I6, and the support beam II17 is fixedly connected with the The slide rail II18 is connected with a slide block II19 that can slide relative to the slide rail II18. The bottom of the detection platform 15 is provided with a support base 16, and the two rows of support frames 10, 14 are respectively fixed on both side edges of the detection platform 15 by fixing de...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap