Device for measuring normal spectral emissivity of non-transparent material

A spectral emissivity and measuring device technology, which is applied in the field of measuring devices for measuring the normal spectral emissivity of non-transparent smooth materials, can solve the problems that the accuracy cannot meet the spectral emissivity measurement, it is difficult to find the spectral emissivity model, etc., and achieve reduction The effect of small spectral emissivity error, fast heating speed and high vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

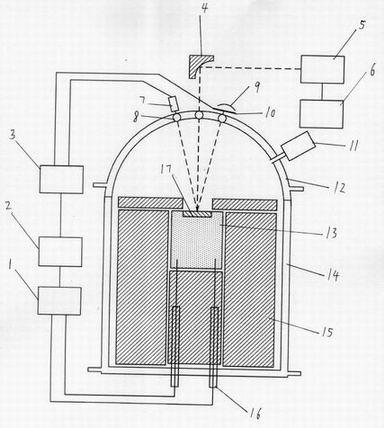

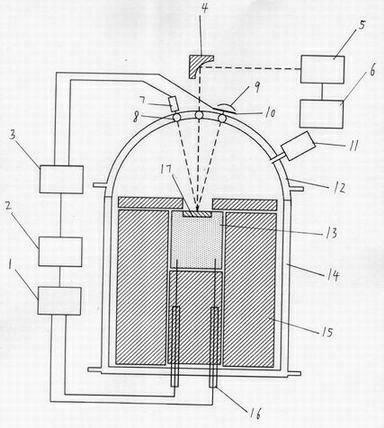

[0008] The embodiments are described in detail with reference to the drawings:

[0009] A device for measuring the normal spectral emissivity of non-transparent materials, which includes a hemispherical water-cooled flange 12, a graphite heating body 13, a graphite heating body is arranged in a cylindrical cavity 14, and a groove 17 is arranged on the top of the graphite heating body. The graphite heating body is connected with a water-cooled electrode 16, and the water-cooled electrode is connected with a high-power DC power supply 1. A heat insulation material 15 is provided outside the graphite heating body, and a hemispherical water-cooled flange is provided on the top of the cylindrical cavity, which is connected to the top of the graphite heating body. There are three observation holes 8 uniformly distributed on the hemispherical water-cooled flange corresponding to the groove of the groove. One of the observation holes is the center of the sphere, and the other two are symm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com