A digital mask-free photoetching aligning deivce based on phase shift moire fringe

A technology of maskless lithography and moiré fringes, applied in the field of maskless lithography, can solve the problems of complex structure, difficult implementation and high cost of the alignment system, and achieve the effects of good reliability, low cost and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention aims to provide a maskless lithography alignment method and device based on digital micromirrors. In order to make the ideas, technical means, image processing related algorithms and advantages of the present invention more clear, the following will be described in detail in conjunction with the accompanying drawings.

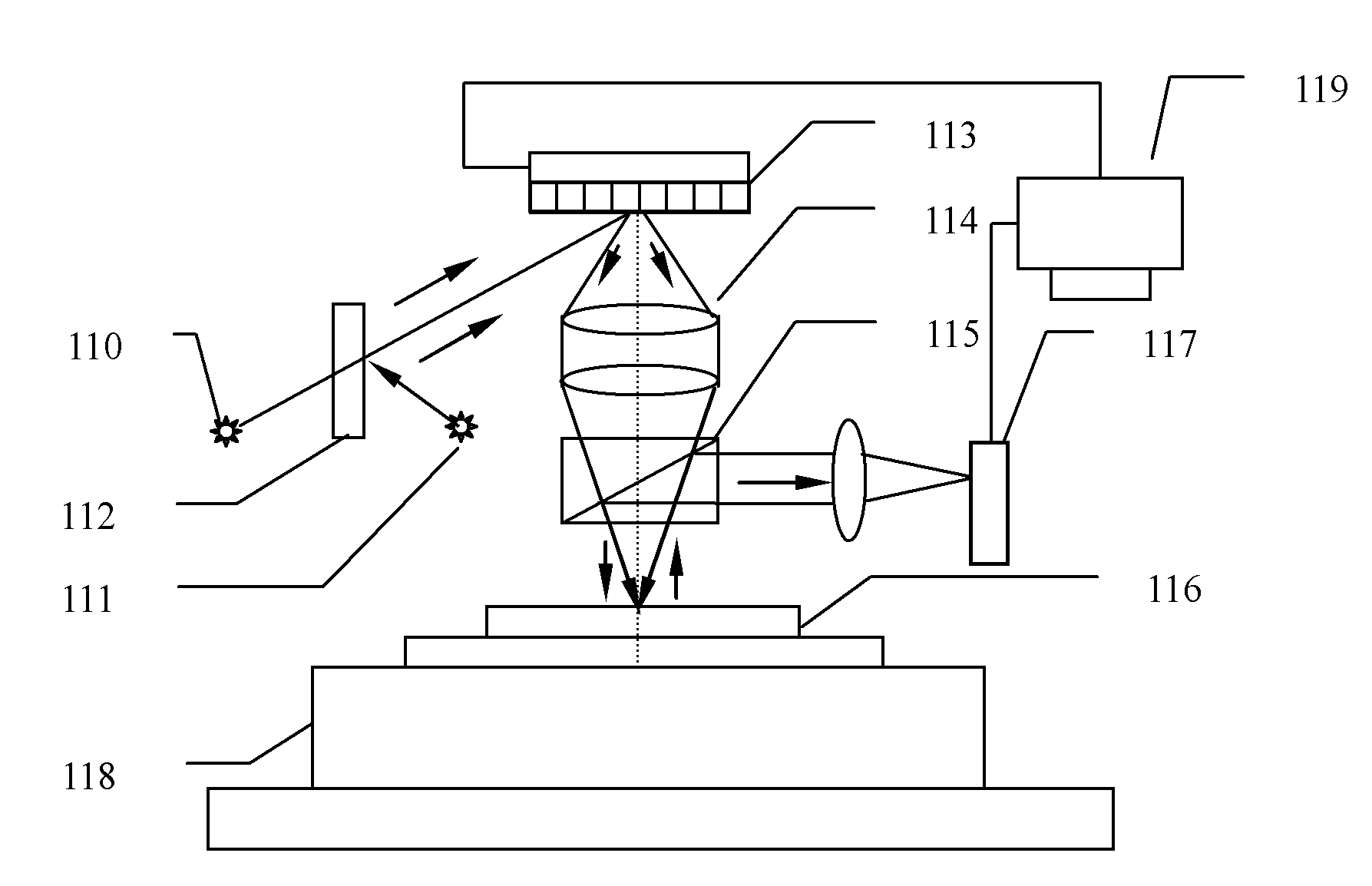

[0028] refer to figure 1 , a method and device for maskless lithography alignment based on digital micromirrors provided by the present invention, the device includes a computer 119, an alignment light source 111, an exposure light source 110, a digital micromirror 113, a lithography objective lens 114, a silicon wafer 116, CCD imaging device 117, displacement workpiece table 118, the first dichroic beam splitter 112 and the second dichroic beam splitter 115; the first dichroic beam splitter 112 receives alignment light and is reflected on the digital micromirror 113; Computer 118 controls The digital micromirror 113 produces a digi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com