Load fault diagnosis detection method and device thereof

A fault diagnosis and detection device technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as indistinguishable short-circuit faults, inconsistency between output and expected value, short circuit between turns of inductance, etc., to improve protection and control reliability , the effect of preventing the further spread of faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

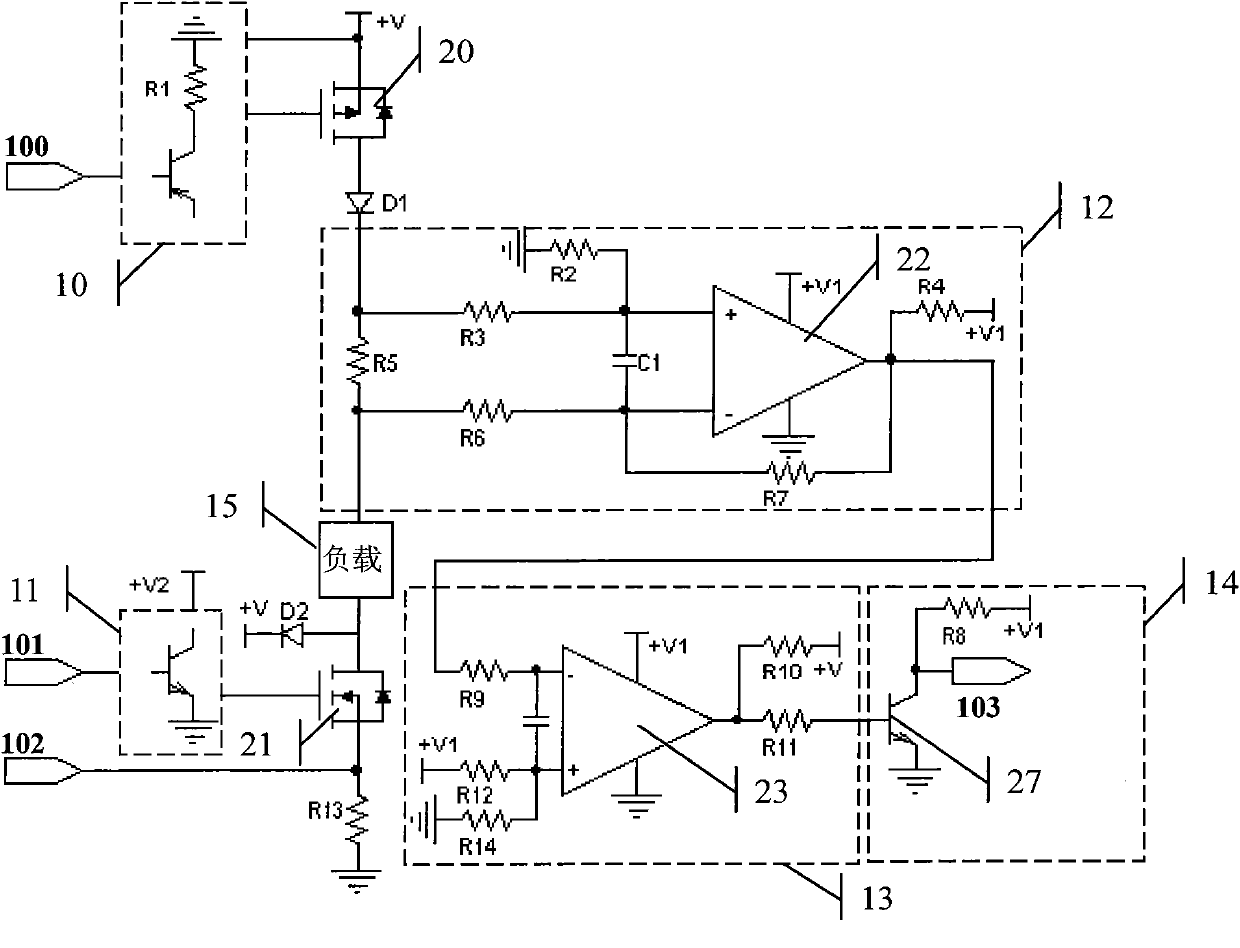

[0048] The working principle, specific structure and preferred embodiments of the load fault diagnosis and detection method and device of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0049] figure 1 It is a schematic block diagram of the load fault diagnosis and detection device of the present invention, which includes a high-end field effect transistor (MOSFET) pre-driver circuit 10, a high-end sampling resistor R5, a drive MOSFET pre-driver circuit 11, a low-end sampling resistor R13, and a signal differential amplifier circuit 12. Comparing circuit 13 and inverting circuit 14 are composed. The high-end MOSFET pre-driver circuit 10 is controlled by the signal 100 to realize the drive control of the high-end field effect transistor 20 and play the role of loading and disconnecting the load driving power supply +V.

[0050] The anode of the diode D1 is connected to the signal output of the high-end field effect trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com