Valve having a magnet bag

A technology of valve needle and valve core, which is applied in the field of valves with magnetic stacks, can solve problems such as high cost, and achieve the effects of improved dynamics, fast switching, and high dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

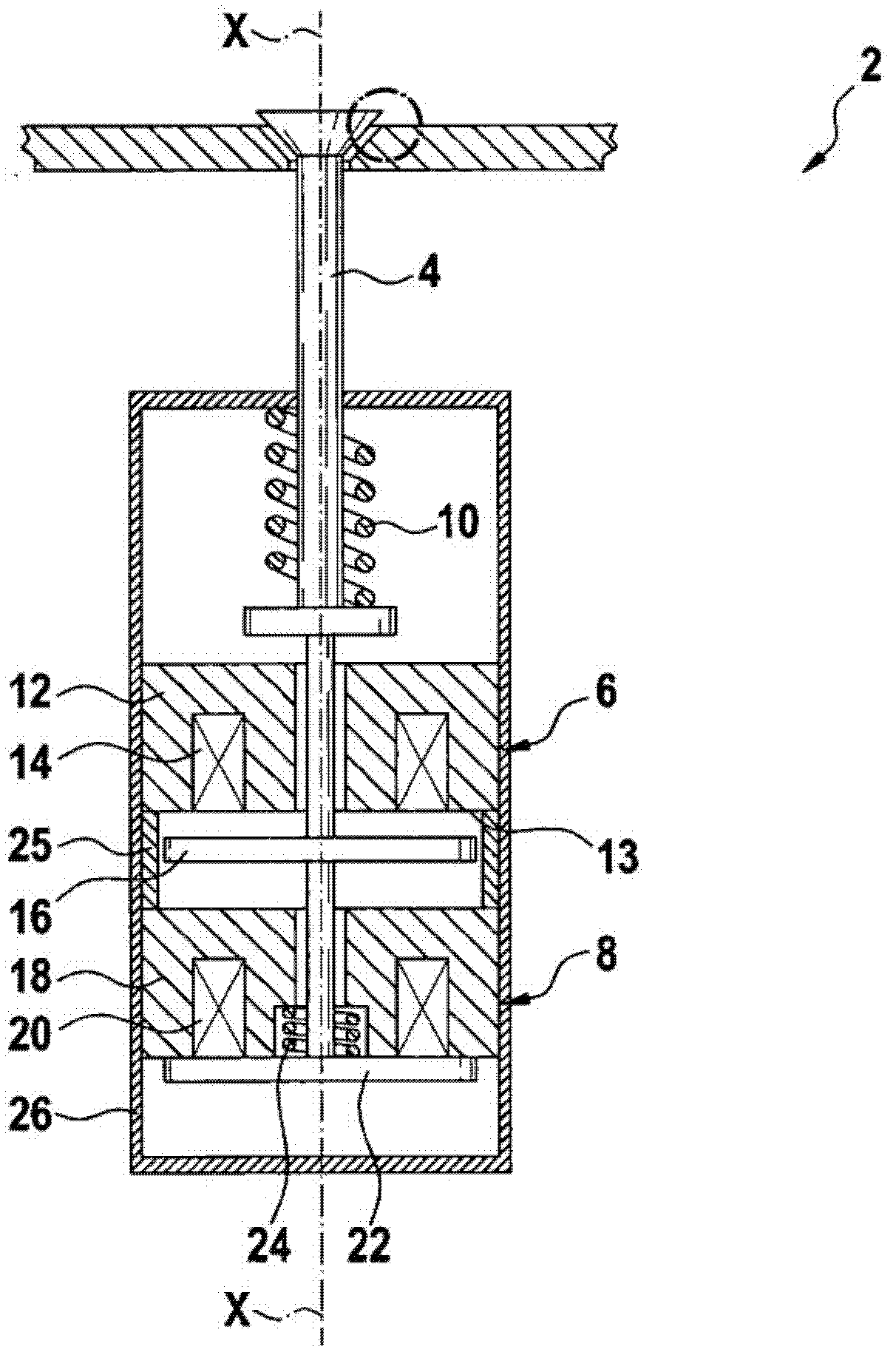

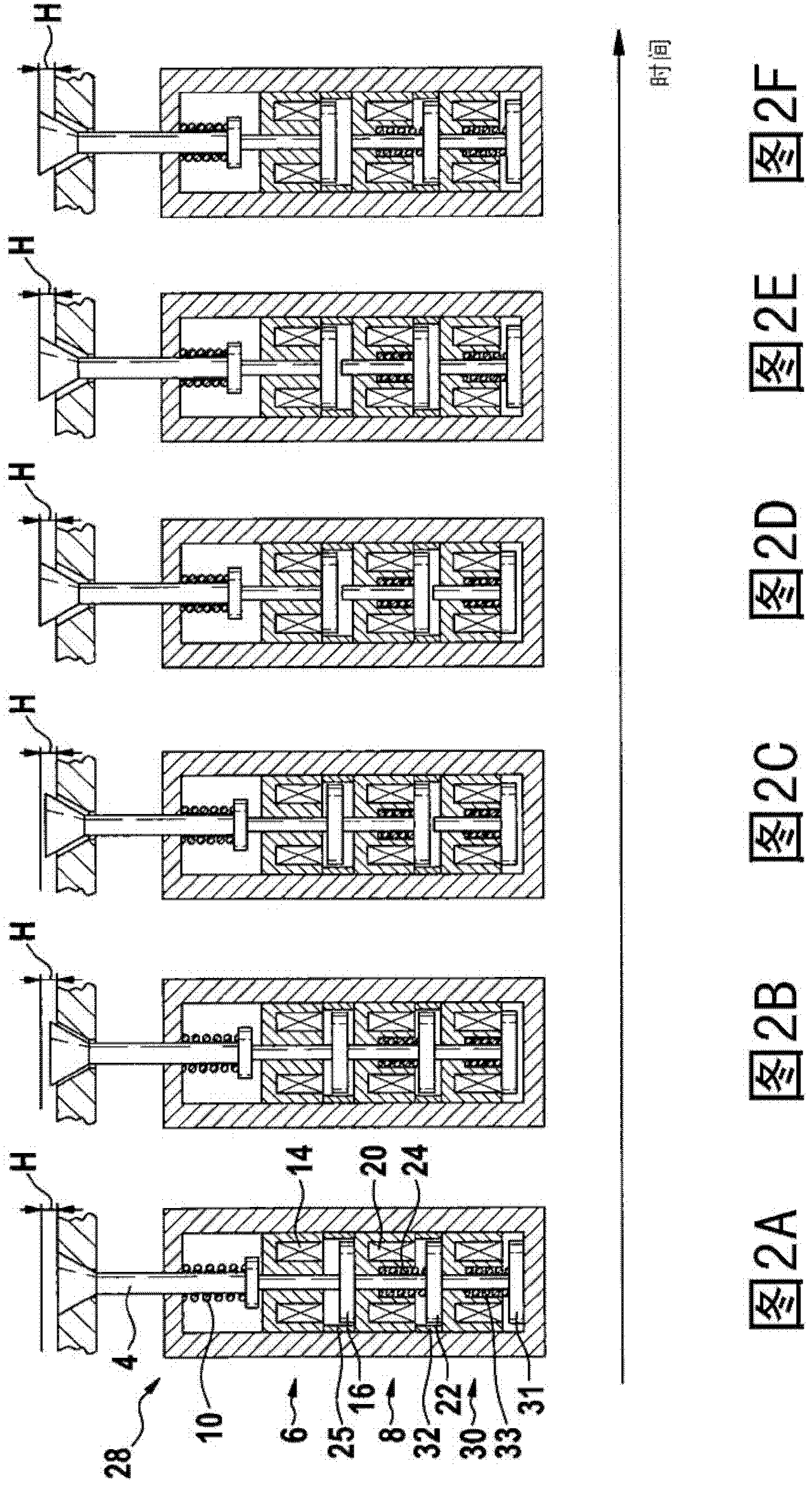

[0032] FIG. 1 shows a first embodiment of a valve 2 according to the invention with a two-stage valve stack. Such a valve 2 can be used, for example, as an injection valve in an internal combustion engine. The valve 2 has a valve needle 4 , a first electromagnetic drive 6 and a second electromagnetic drive 8 . The first electromagnetic drive 6 is provided for direct actuation of the valve needle 4 , while the second electromagnetic drive 8 actuates the valve needle via the first electromagnetic drive 6 . The first and second electromagnetic drives 6 , 8 can be moved back into the zero position by means of the main return spring 10 .

[0033] The first electromagnetic drive 6 has a first magnetic circuit 12 , a first coil 14 and a first armature element 16 . The first coil 14 can be energized and used as a magnetic source voltage which flows through the first magnetic circuit 12 . The first magnetic circuit 12 has pole shoes 13 via which the magnetic field can emerge from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com