Unloading type static-dynamic pressure shafting unit for machine tool

A technology for pressing shafts and machine tools, which is applied in metal processing mechanical parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of the comprehensive accuracy of spindle rotation, reduce the rotation accuracy of the spindle, etc., to improve the rotation accuracy and improve the rotation accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

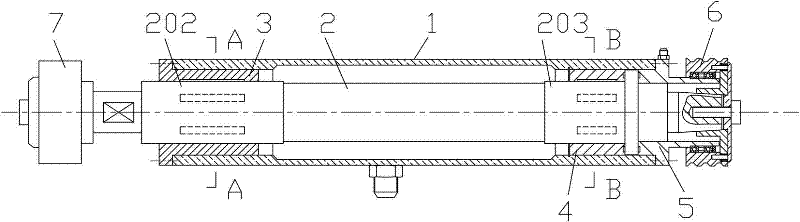

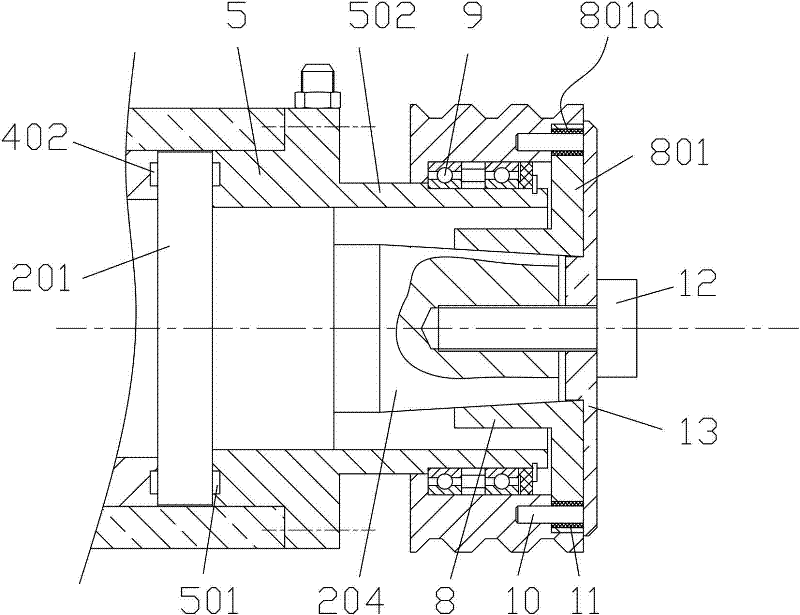

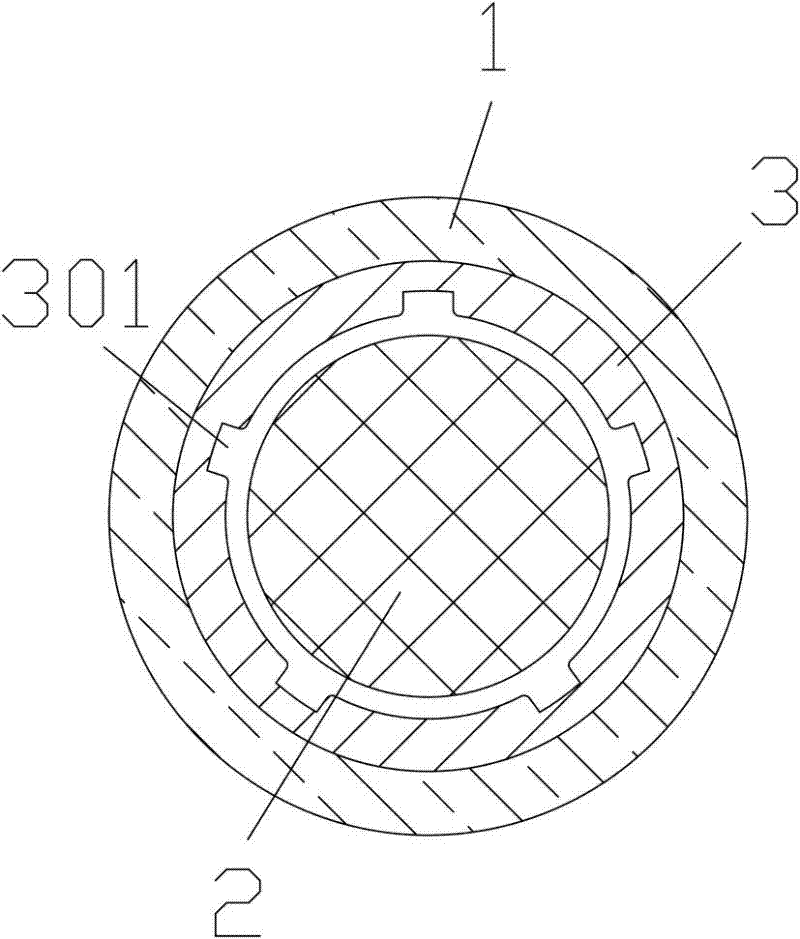

[0037] Examples, see attached figure 1 , 2 , 3, 4; an unloading static and dynamic pressure shafting unit for machine tools, the shafting unit of the present invention can be used for machine tools or grinding machines, etc., this embodiment takes grinding machines as an example, but it is not limited thereto, it includes Spindle box 1, spindle 2. The spindle box is installed on the machine tool. At the same time, the spindle 2 is installed in the spindle box with two ends extending out. The rear end of the spindle is fixed with a transmission wheel 6 for connecting with an external power source. , to drive the main shaft to rotate, because in the present embodiment, a grinding machine is used as an example, so a grinding wheel 7 is installed on the front end of the main shaft, and if it is a lathe, a tool can be installed, because it is a known technology in the art, so it will not be described in detail here , the front bearing bush 3, the rear bearing bush 4 and the rear p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com