Lost foam cutting equipment

A cutting equipment and technology of lost foam, applied in metal processing, etc., can solve the problems that the cutting accuracy cannot be effectively guaranteed, the foam connection surface is difficult to fit, and the sliding card has no fine-tuning function, so as to ensure the processing accuracy, light weight and save energy. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A specific embodiment of the present invention will be described in detail below with reference to the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

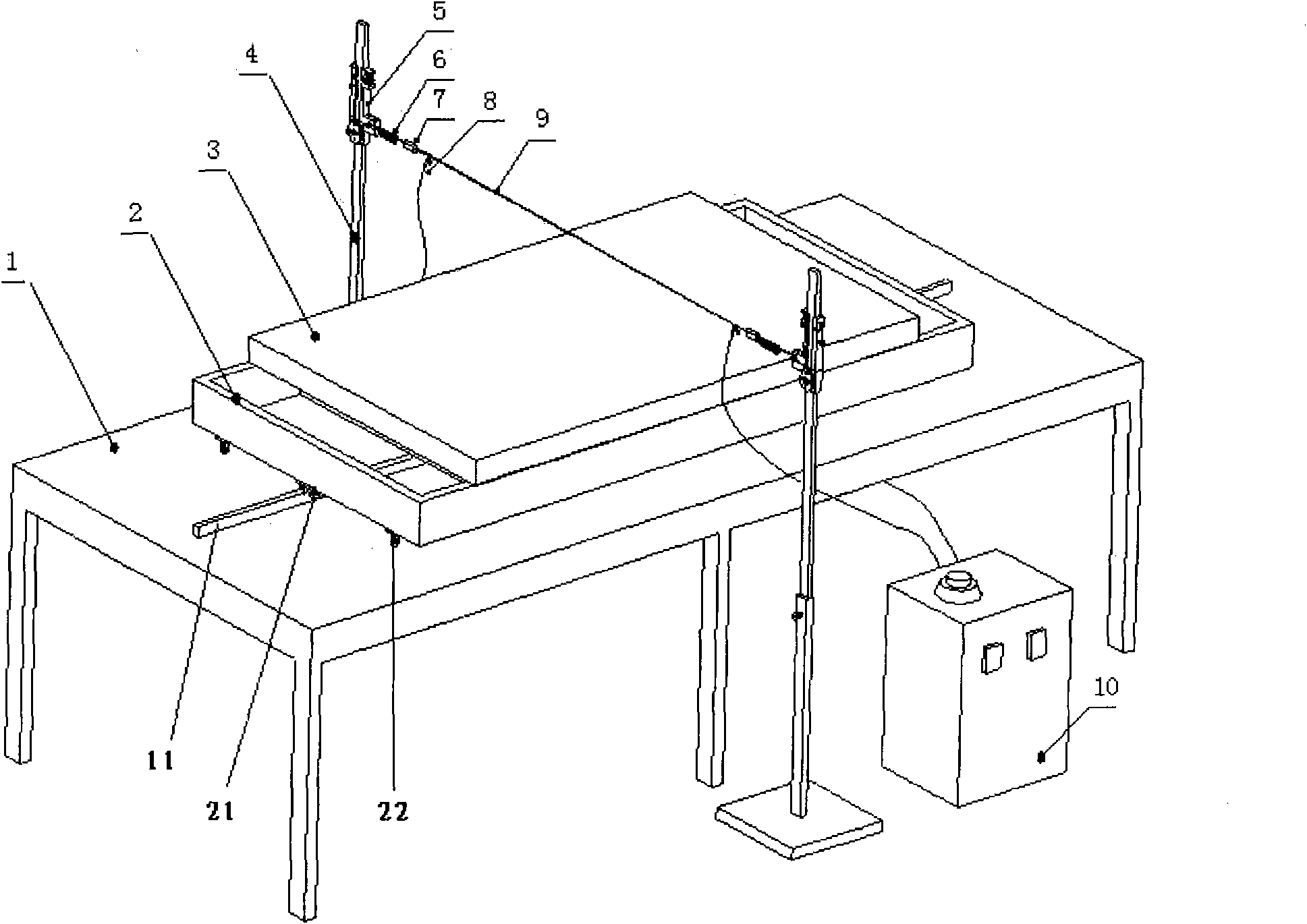

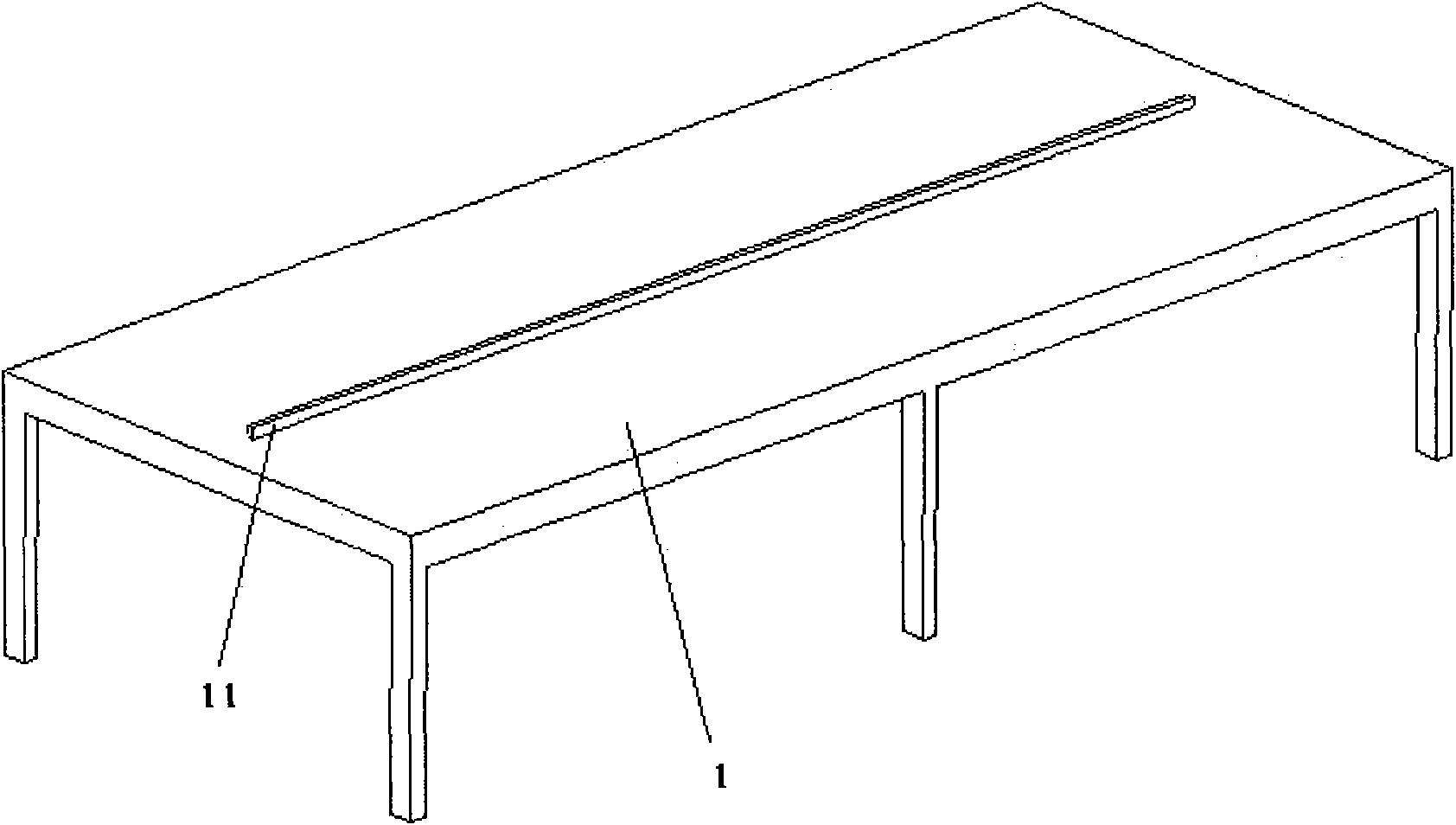

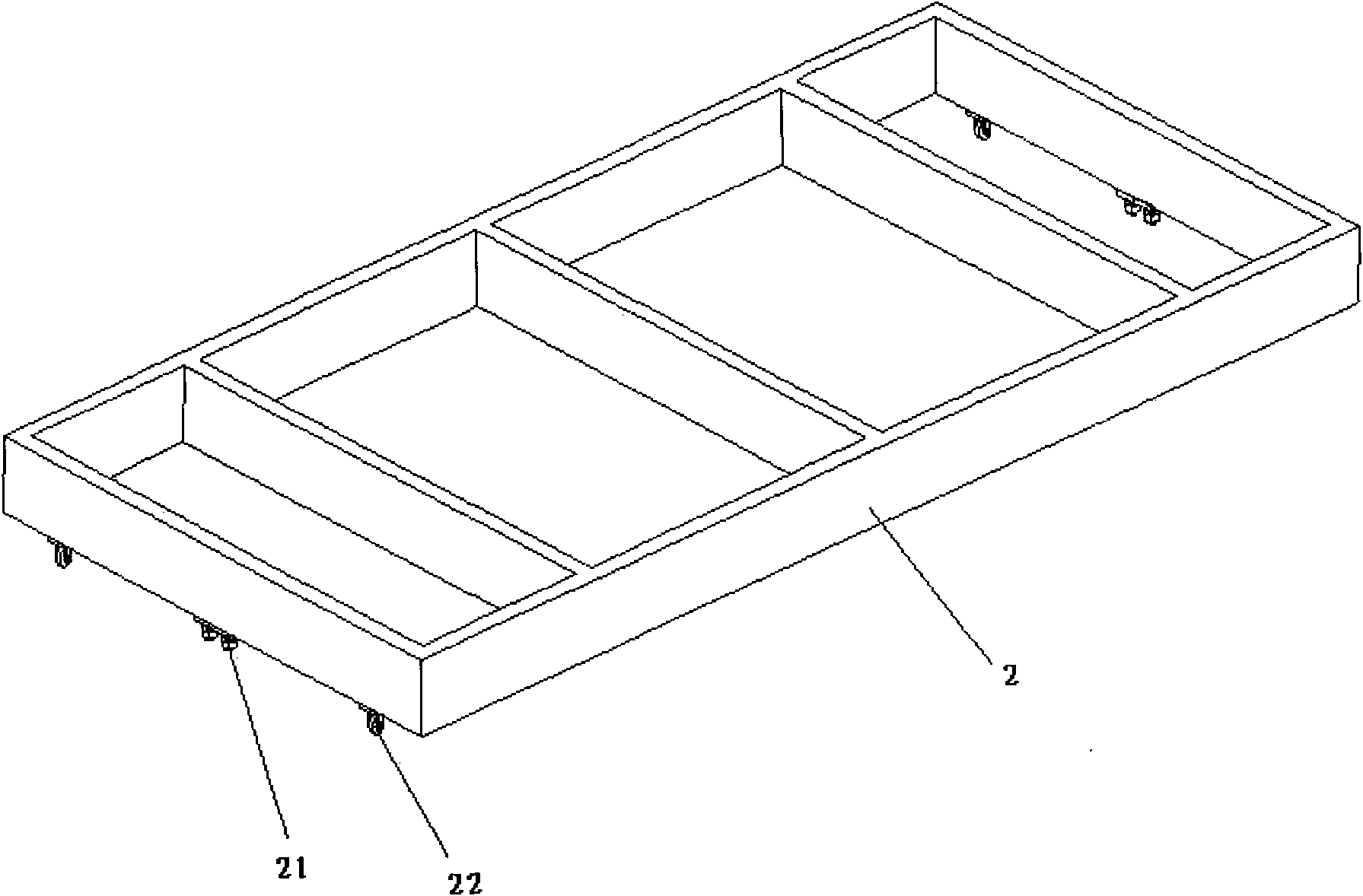

[0025] Such as Figure 1 to Figure 3 As shown, the lost foam foam cutting equipment of the present invention includes a sliding bracket 2 provided on the reference platform 1, and a foam cutting plate 3 located on the sliding bracket 2 (using foam material to replace the glass plate in the prior art, The cutting plate can be more closely aligned with the foam to be cut), and the foam cutting plate 3 is used to support the foam to be cut. Two support frames 4 are provided symmetrically on both sides of the reference platform 1. The column of the support frame 4 is provided with a sliding card assembly 5 that can slide relative to the column. The function of the sliding card assembly 5 is to draw the energized electric heating i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com