Unidirectional plunger type oil cylinder of hydraulic press

A hydraulic press, plunger technology, applied in punching machines, presses, fluid pressure actuating devices, etc., can solve problems such as damage to cylinders and plunger rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

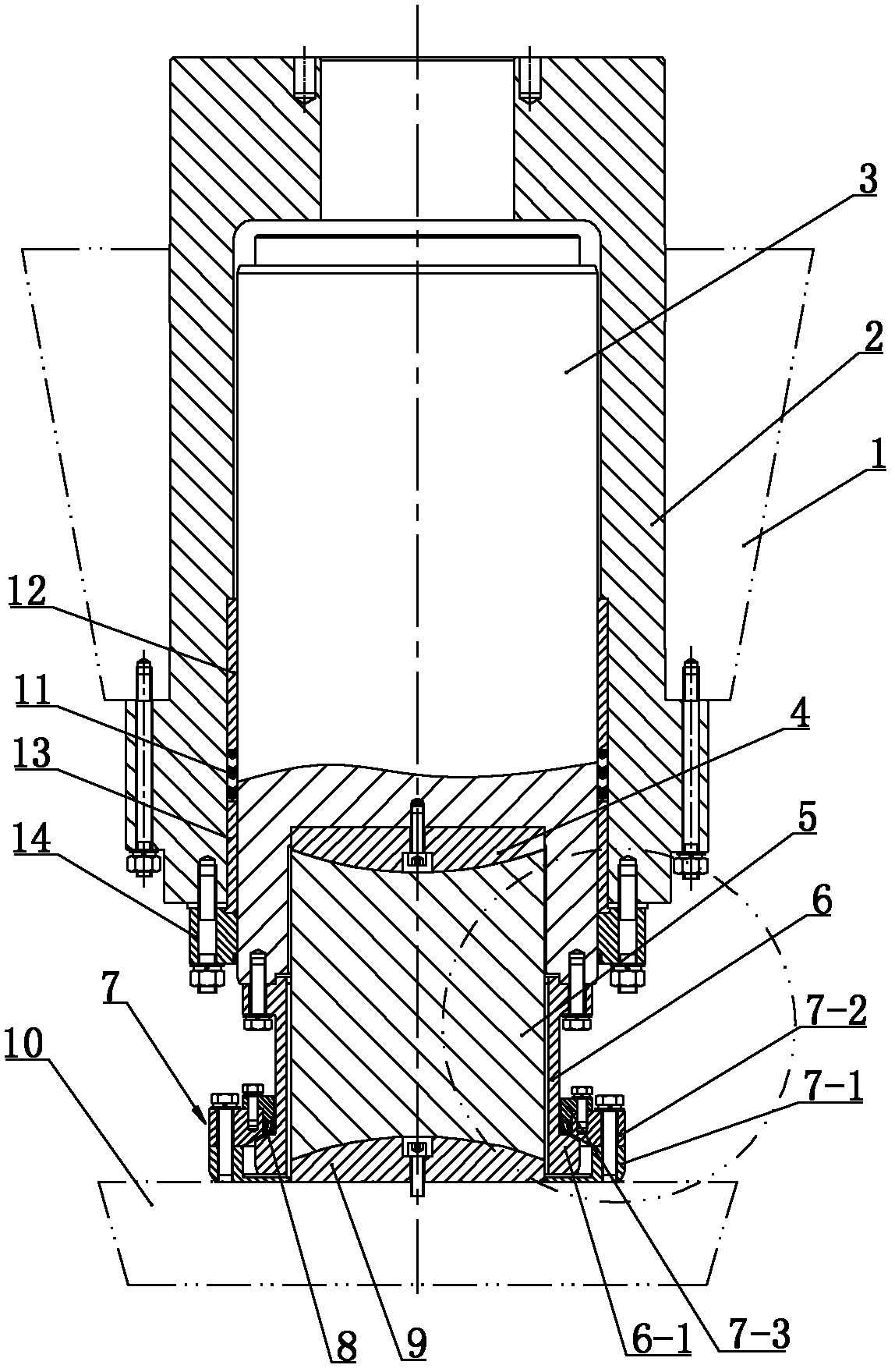

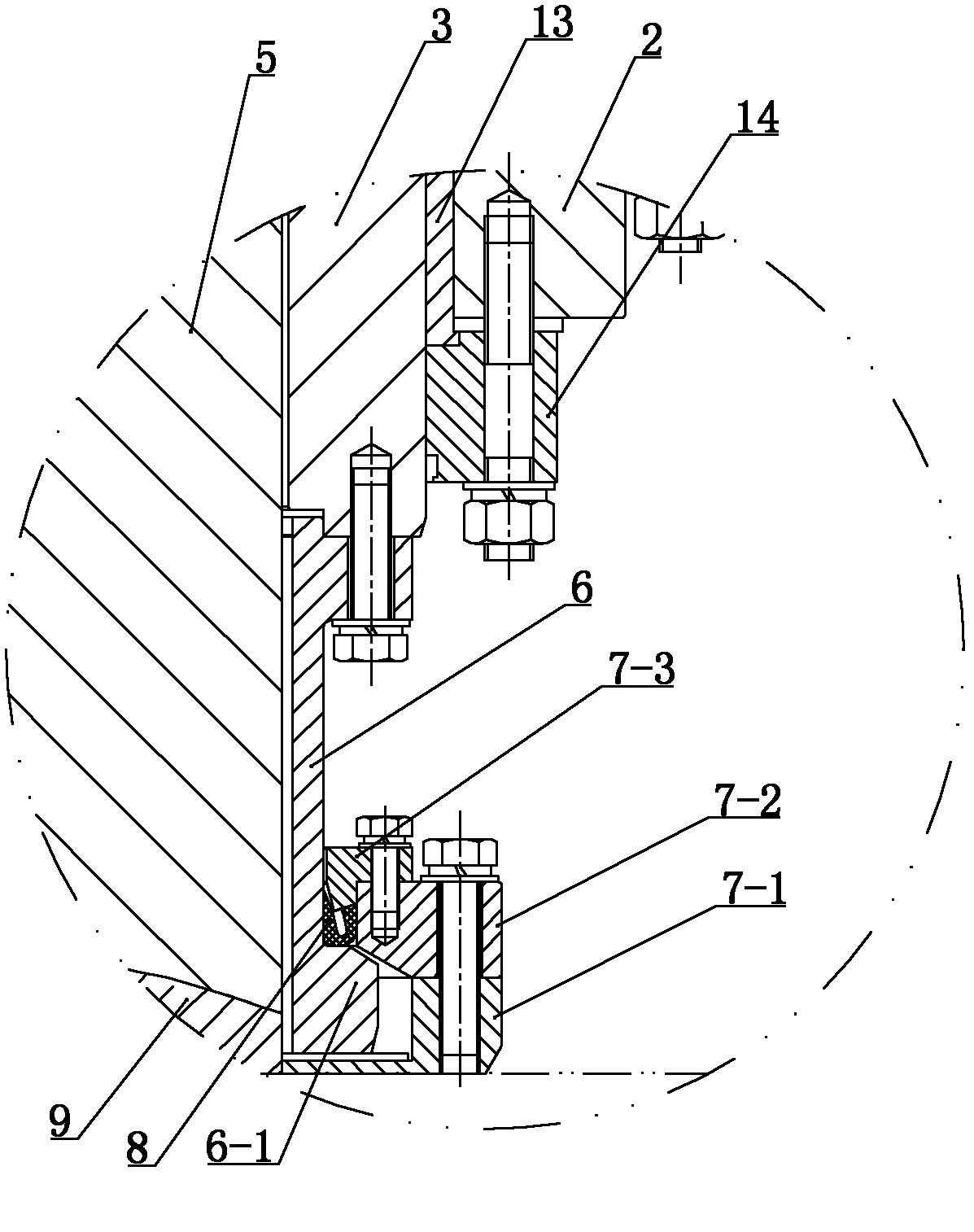

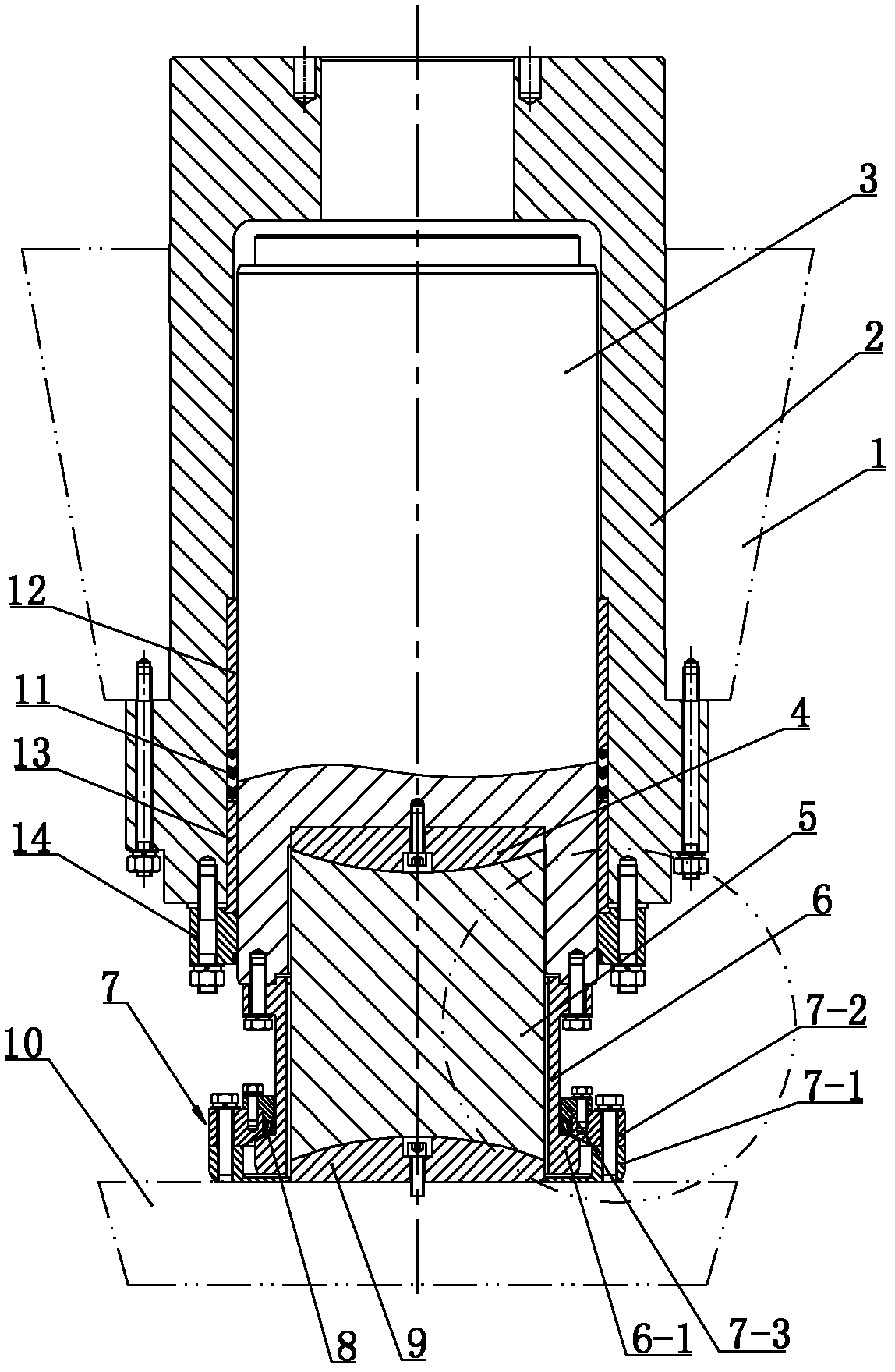

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0016] see Figure 1-2 , a one-way plunger cylinder for a hydraulic machine, including a cylinder body 2 installed on the upper beam 1 of the hydraulic machine, a plunger rod 3 placed in the cylinder body, and a guide structure and a seal between the plunger rod and the inner wall of the cylinder body . The lower end of the plunger rod is formed with a cylindrical cavity, and the first spherical pad 4 and the spherical column 5 forming a spherical fit are arranged in the cylindrical cavity from top to bottom, and the first spherical pad is fixed in the cylindrical cavity by screws. bottom end. The spherical column protrudes from the lower end of the plunger rod, and its exterior is covered with a support sleeve 6 fixed on the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com