Removing method of lifting cover for hoisting

A technology for hoisting and hoisting equipment, which is applied in the direction of transportation, packaging, and load hanging components, etc. It can solve the problems that the crane occupies the site for a long time, affects other constructions, and has high safety risks, so as to reduce the workload of preparations, improve work efficiency, The effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

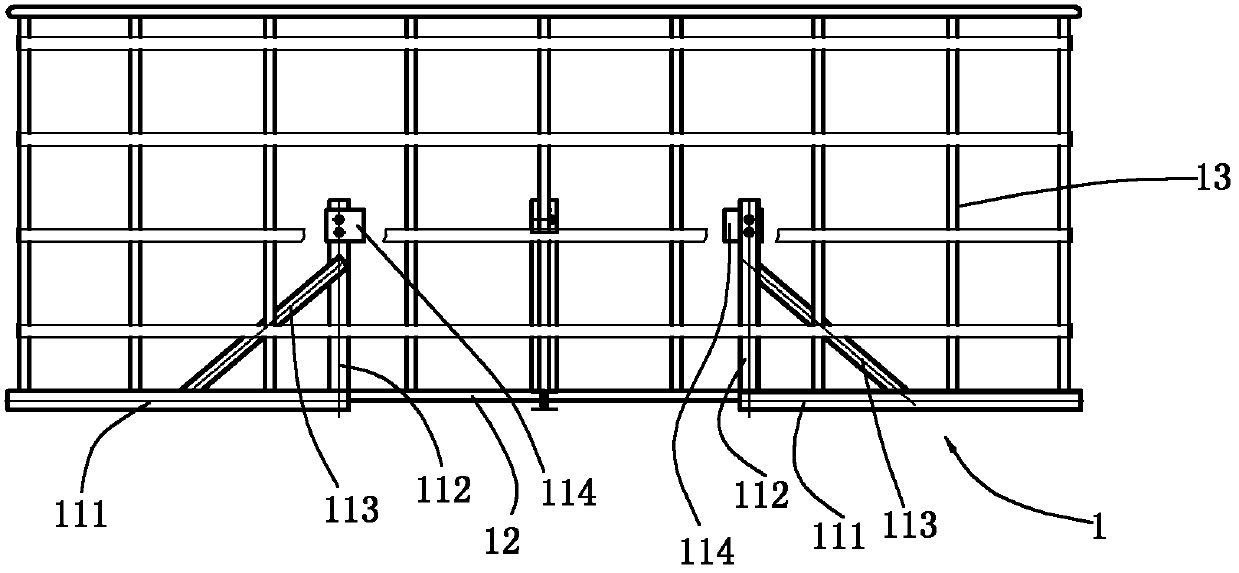

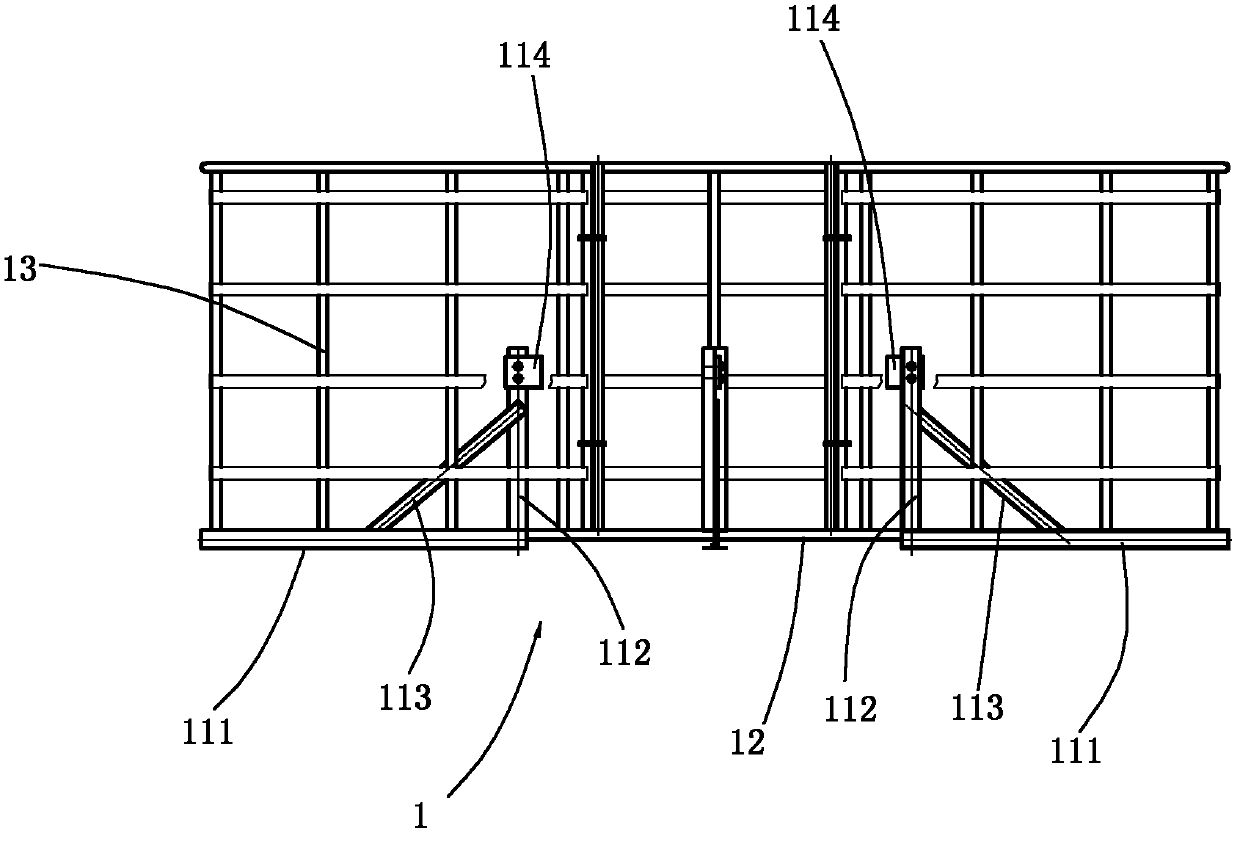

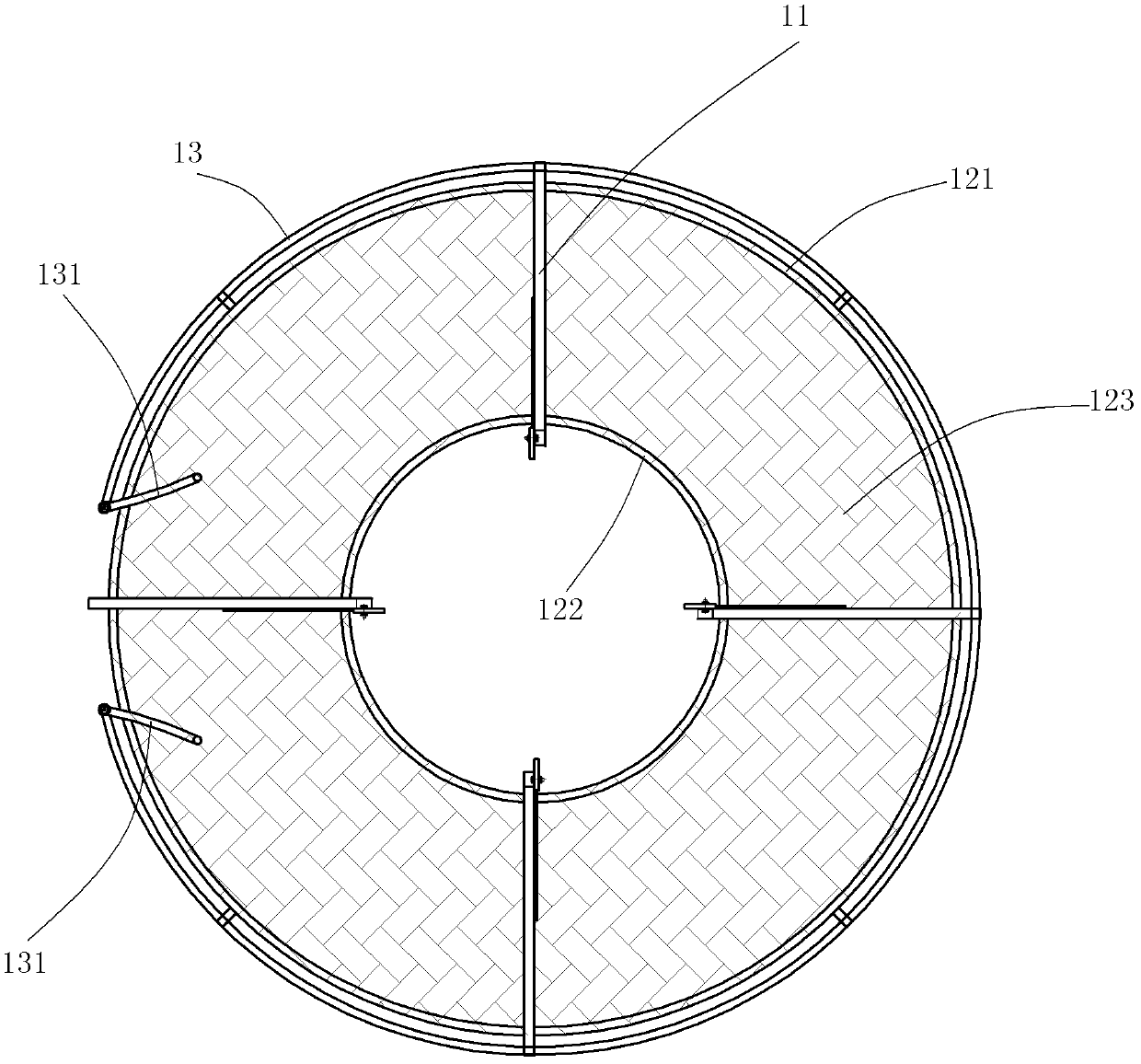

[0030] Such as Figure 1 to Figure 7 As shown, the structure of the working platform 1 used in the hoisting lifting cover removal method is as follows:

[0031] The operating platform includes:

[0032] There are four sets of support assemblies 11 in this embodiment, and each support assembly includes a beam 111 , a vertical beam 112 , a diagonal stay 113 and a connecting plate 114 . Wherein, one end of the vertical beam is vertically welded on one end of the cross beam, and the two ends of the diagonal stays are respectively welded to the middle of the cross beam 111 and the vertical beam 112 to increase the rigidity of the work platform. The vertical beam 112 and the cross beam 111 are the main load-bearing beams of the work platform, and are all made of channel steel.

[0033] The connecting plate 114 is a connecting member between the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com