Time optimal grab bucket operation method

A time-optimized and operating method technology, applied in the direction of transportation and packaging, load suspension components, etc., can solve the problems that the maximum capacity of the trolley cannot be fully utilized, the installation, commissioning and maintenance work is complicated, and the cycle time cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

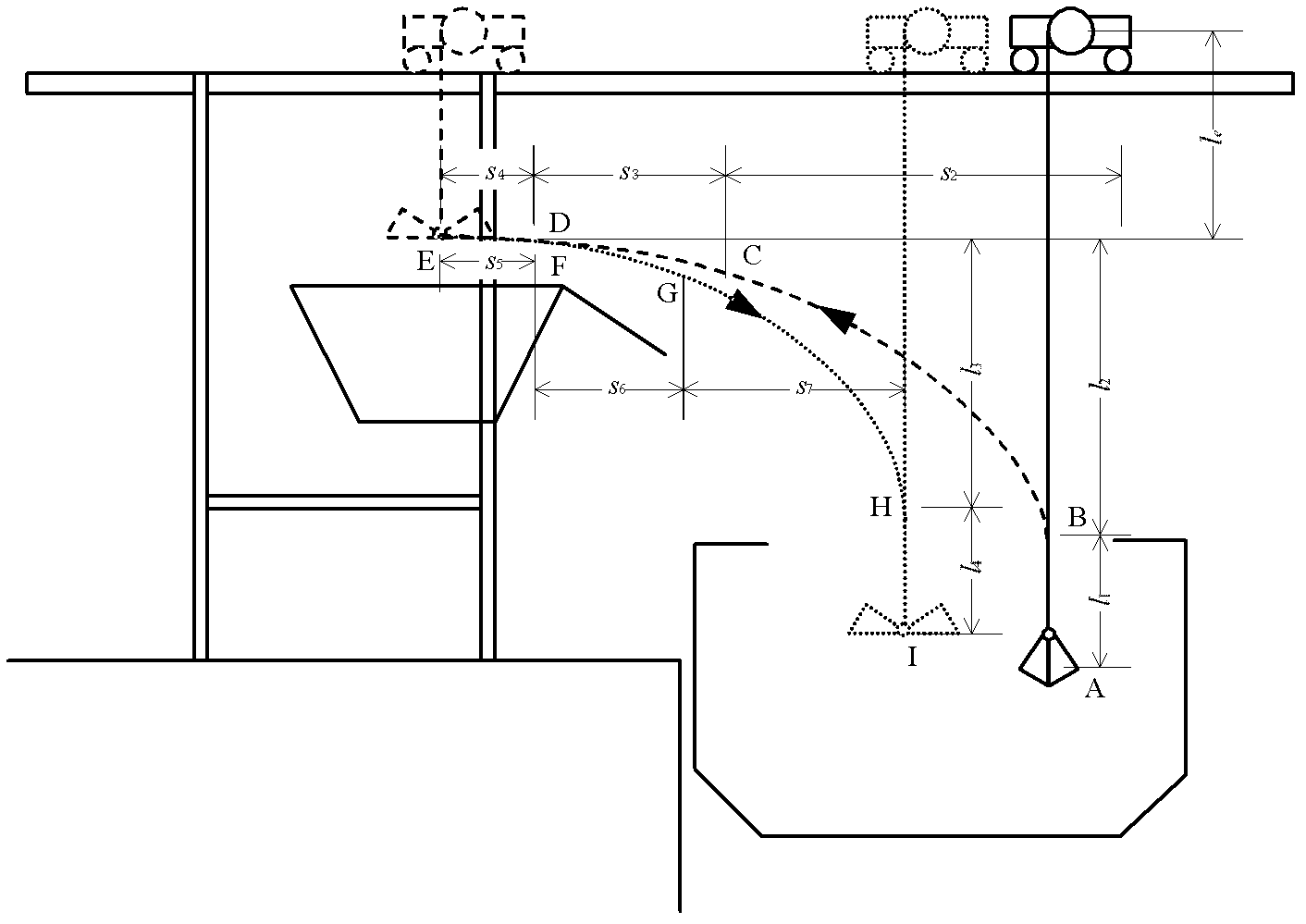

[0066] The present invention will be described in further detail below in conjunction with the accompanying drawings.

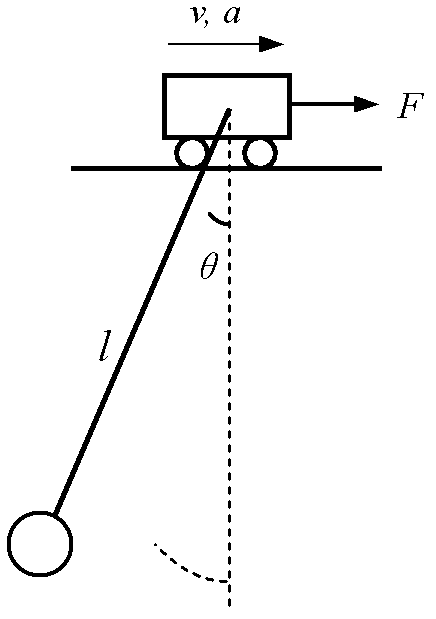

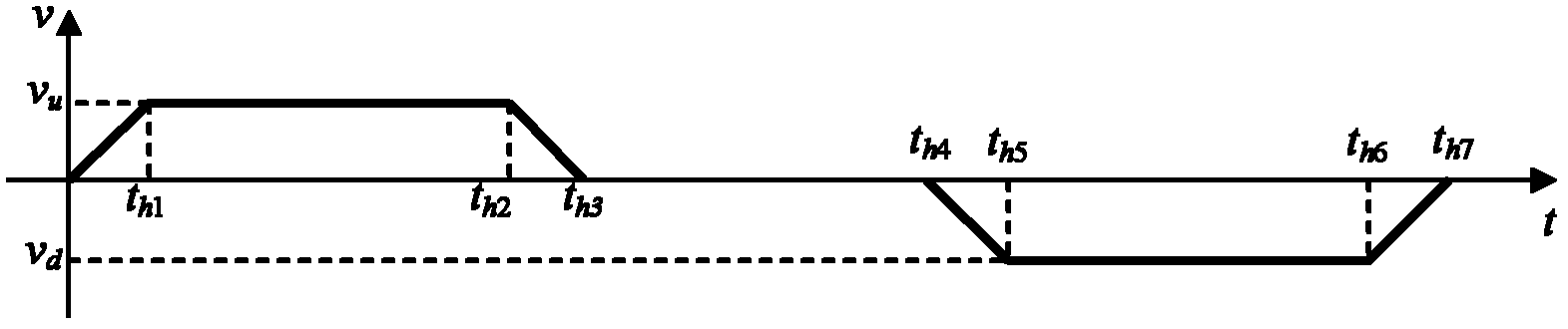

[0067] Shortening the cycle time needs to solve two problems: one is to shorten the running time of the grab bucket, and the other is to prevent the grab bucket from swinging undesirably during operation. The former problem can be solved by controlling the lifting mechanism and the trolley to move simultaneously so that the grab runs along the shortest path. The latter problem is the swing control problem, which needs to control the movement of the trolley so that the grab does not produce undesired swings. These two issues need to be considered simultaneously. For the sway control problem, experienced drivers usually use the method of following the car to eliminate the swing of the grab, which means that when the car accelerates / decelerates in a specific way, the residual swing of the grab may be zero. Therefore, the first problem that needs to be solved i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com