Structure having two independent turbochargers of combustion engines and operating method thereof

A technology for turbochargers and internal combustion engines, applied to internal combustion piston engines, combustion engines, machines/engines, etc., can solve the problem of high cost and achieve the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

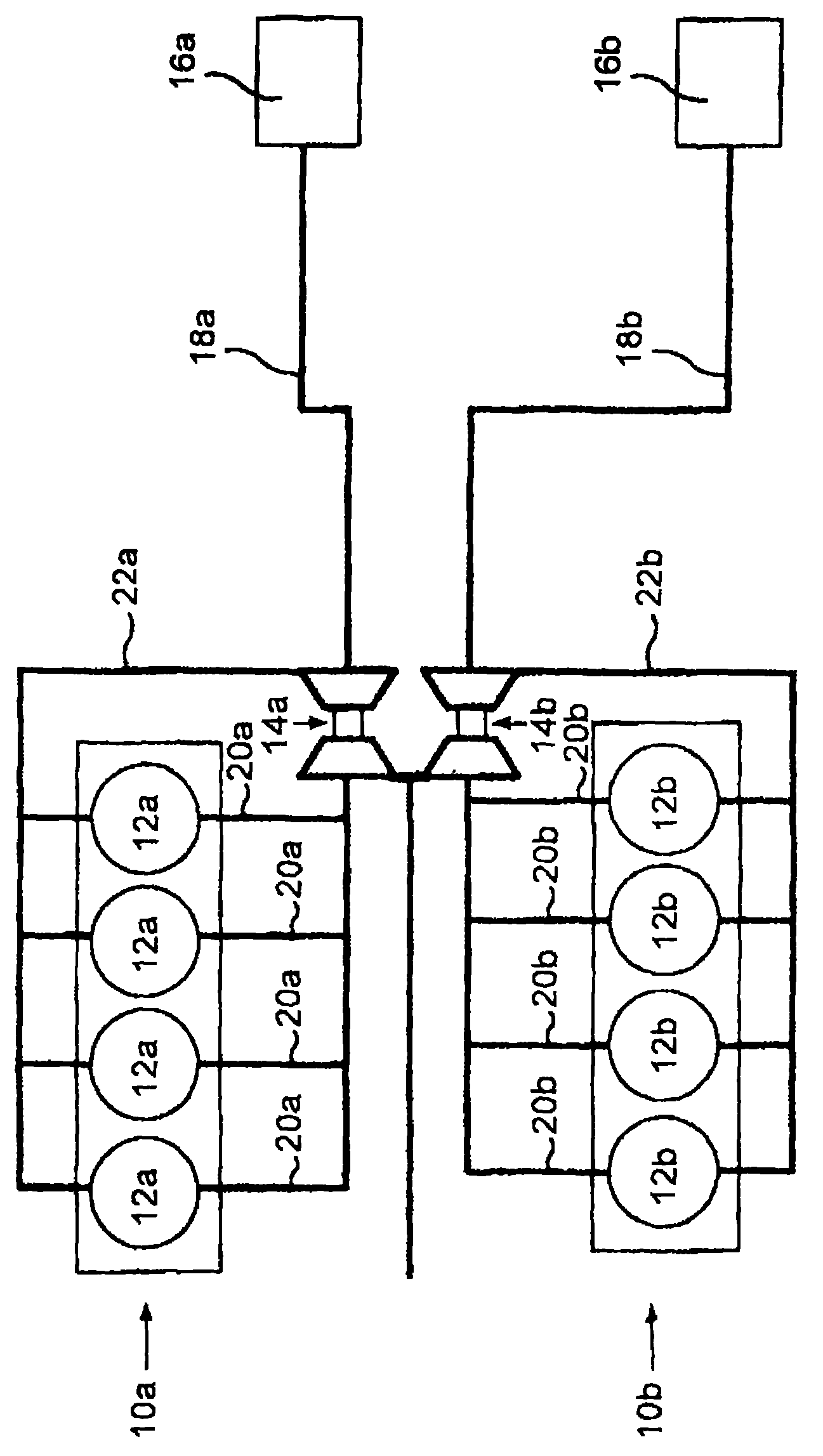

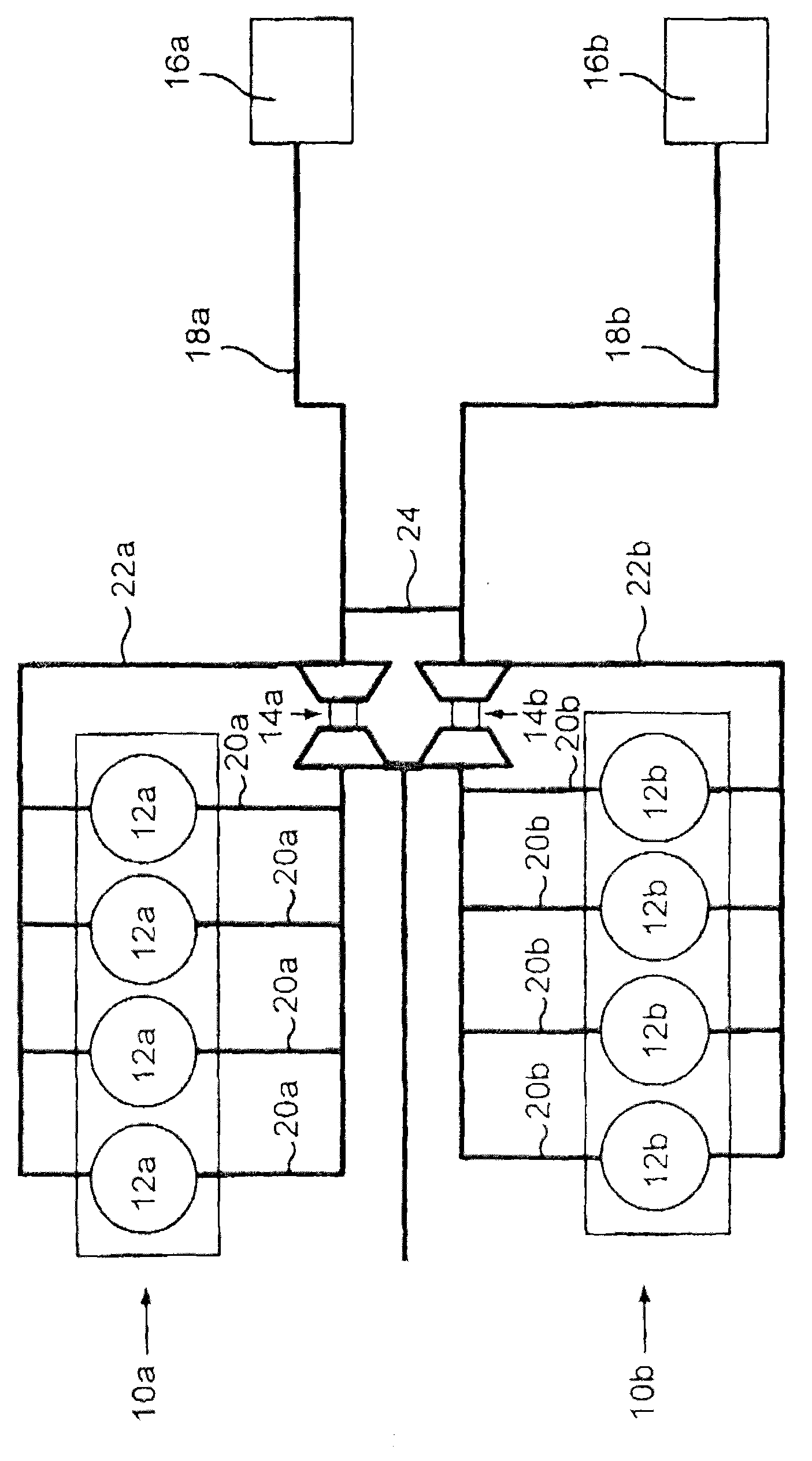

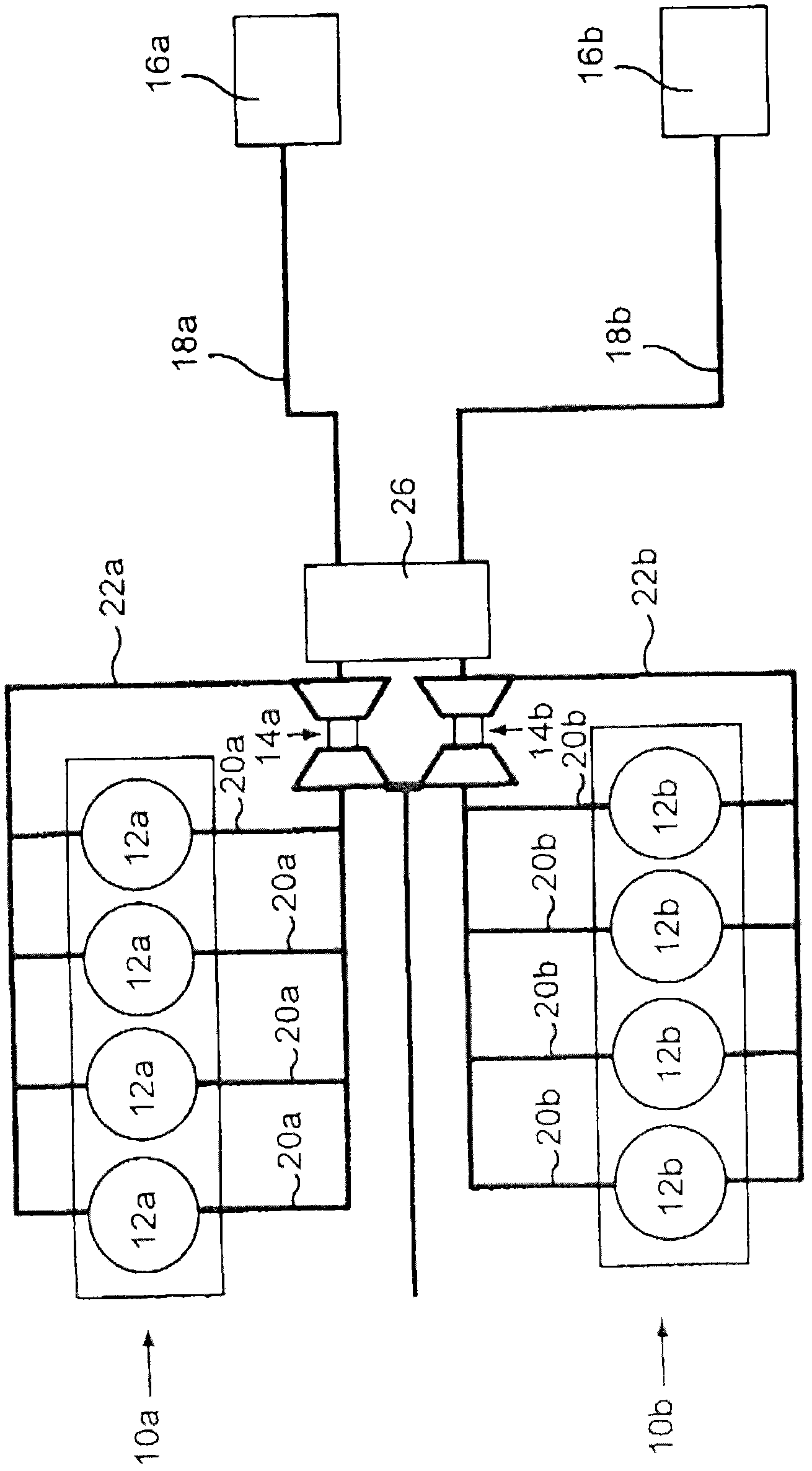

[0016] The internal combustion engine has two cylinder banks 10a, 10b which each have four cylinders 12a or four cylinders 12b. A turbocharger 14a is assigned to the first cylinder bank 10a and a turbocharger 14b is assigned to the second cylinder bank 10b. The purpose of the turbocharger is to press filtered air (clean air) into the cylinders and to utilize the pressure of the exhaust gases expelled from the cylinders there. In this case, a clean air filter 16a, 16b is assigned to each turbocharger 14a, 14b, and a clean air line 18a, 18b is connected downstream of the clean air filter 16a, 16b. The air (charge air) compressed by each turbocharger 14a, 14b is then directed to the cylinder 12a or 12b via conduit 20a or 20b. The exhaust gas recirculation line 22a or 22b guides the exhaust gas to the turbocharger 14a or 14b.

[0017] According to the prior art, the two turbochargers 14a, 14b work completely independently of each other, there is no connection between the clean a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com