Structure capable of reducing heating effect of air inflow of single-screw compressor

A single-screw compressor and heating effect technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of reducing energy efficiency of single-screw compressors, heating intake air, etc., to reduce energy consumption and increase intake air Mass flow, reducing the effect of intake air heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

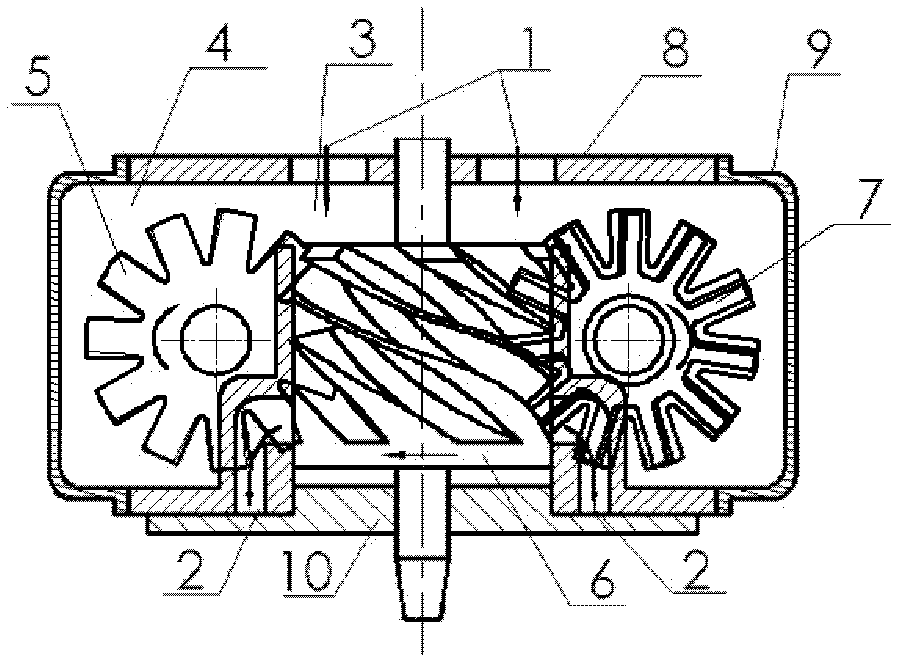

[0016] figure 1 It is a typical oil injection lubricated single-screw compressor structure, the intake chamber 3 at the end of the rotor in the casing is open and communicated with the star wheel chambers 4 on both sides, and the volume between the teeth of the screw rotor 6 rotor slots is also directly connected to the The star wheel room is directly connected. The gas in the star wheel chamber is heated by factors such as the casing 8, lubricating oil, and leakage gas, and the temperature is higher than the intake air temperature. The star wheel chamber communicates with the air intake chamber and has a large communication area, especially under the high-speed rotation of the star wheel and its bracket 7, the high temperature gas in the star wheel chamber is fully mixed with the intake air, and the intake air is heated.

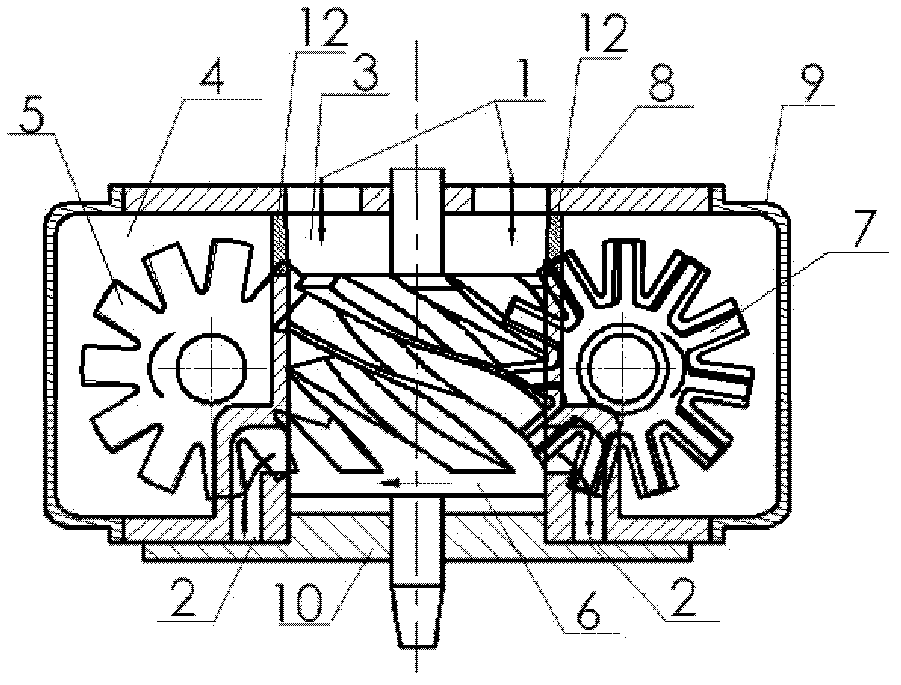

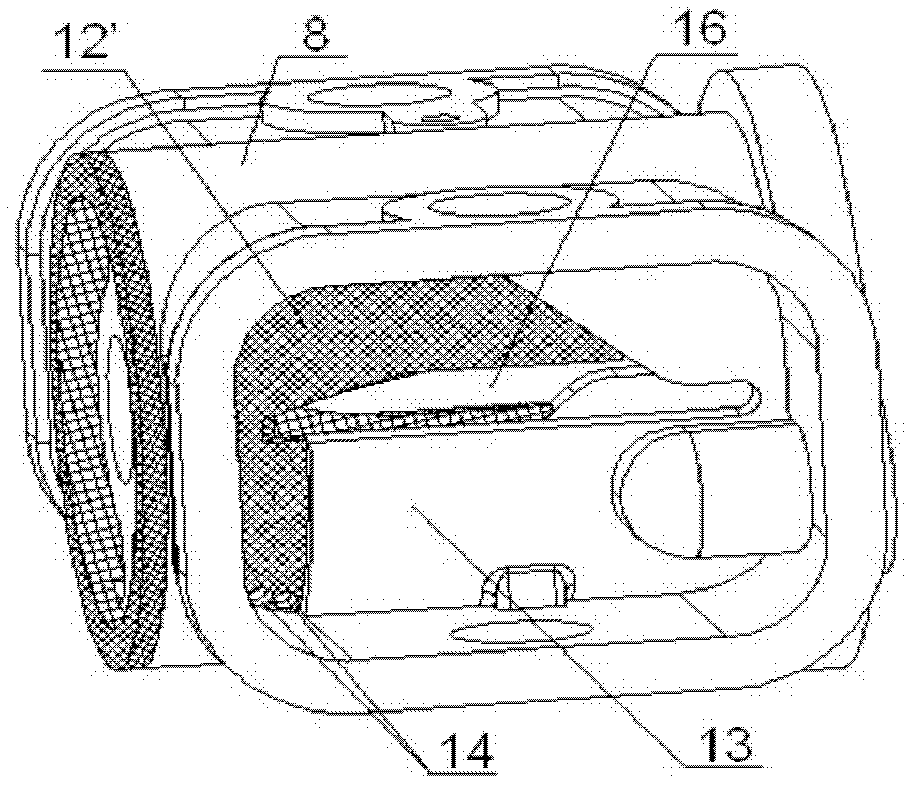

[0017] Such as figure 2 As shown, an example of the structure of the present invention is to use the intake partition wall 12 to isolate the communicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com