Method for diagnosing failure of airplane generator bearing based on GentleBoost

A generator bearing and fault diagnosis technology, applied in the direction of mechanical bearing testing, etc., can solve problems such as overfitting, lack of theoretical basis, and increase the complexity of calculation, and achieve increased robustness, high fault recognition rate, and improved classification. The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

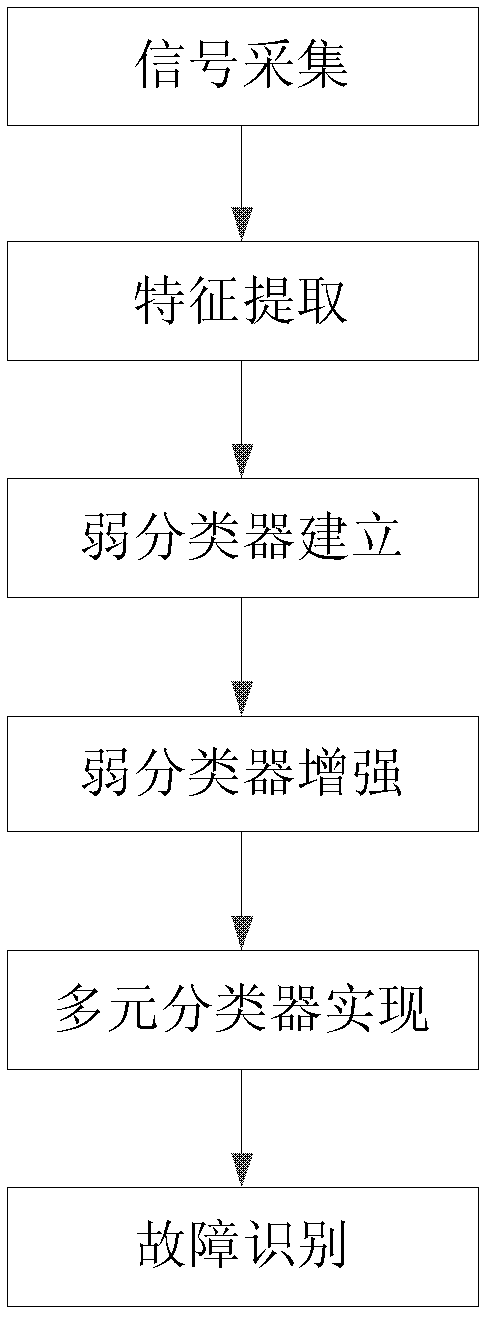

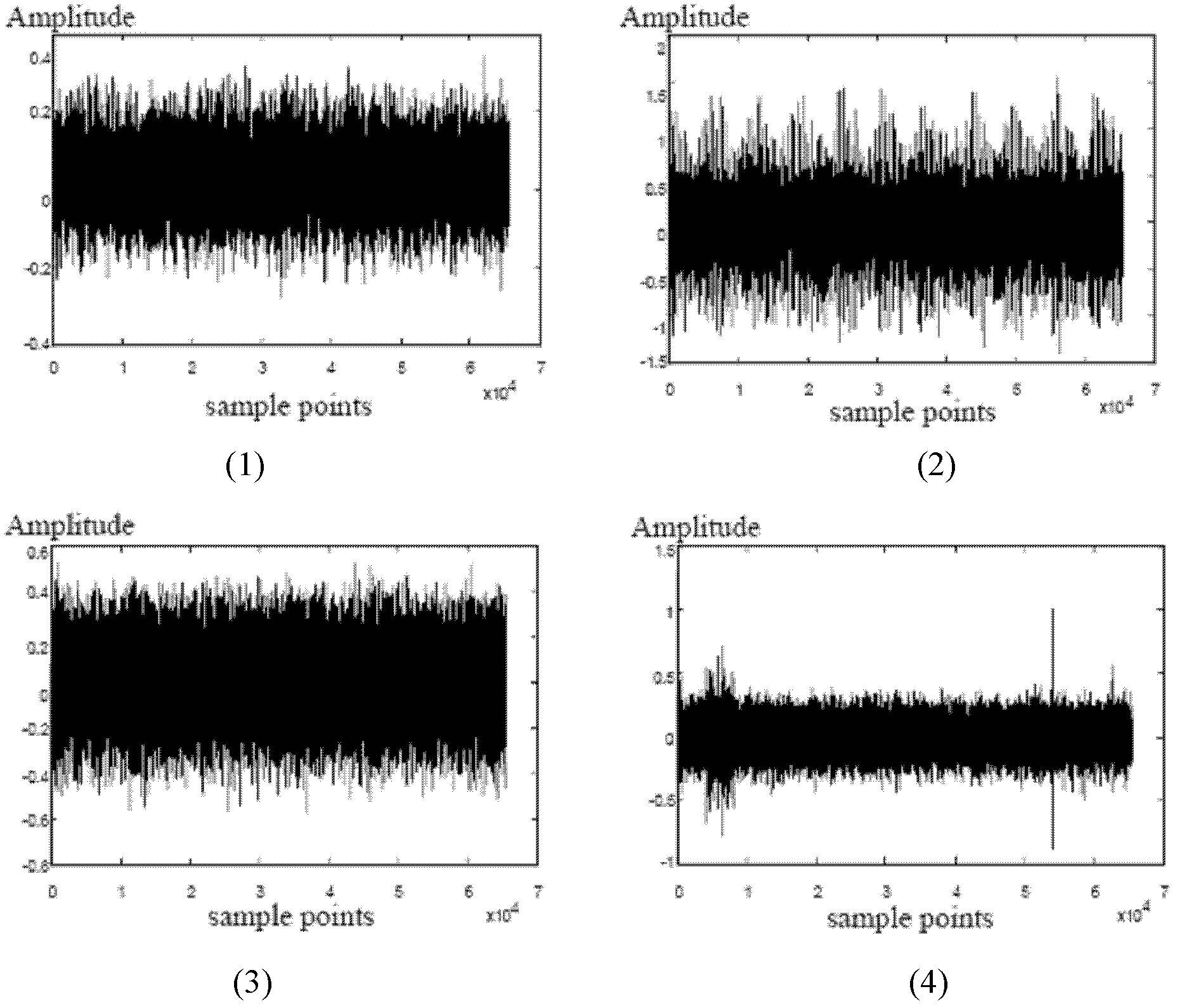

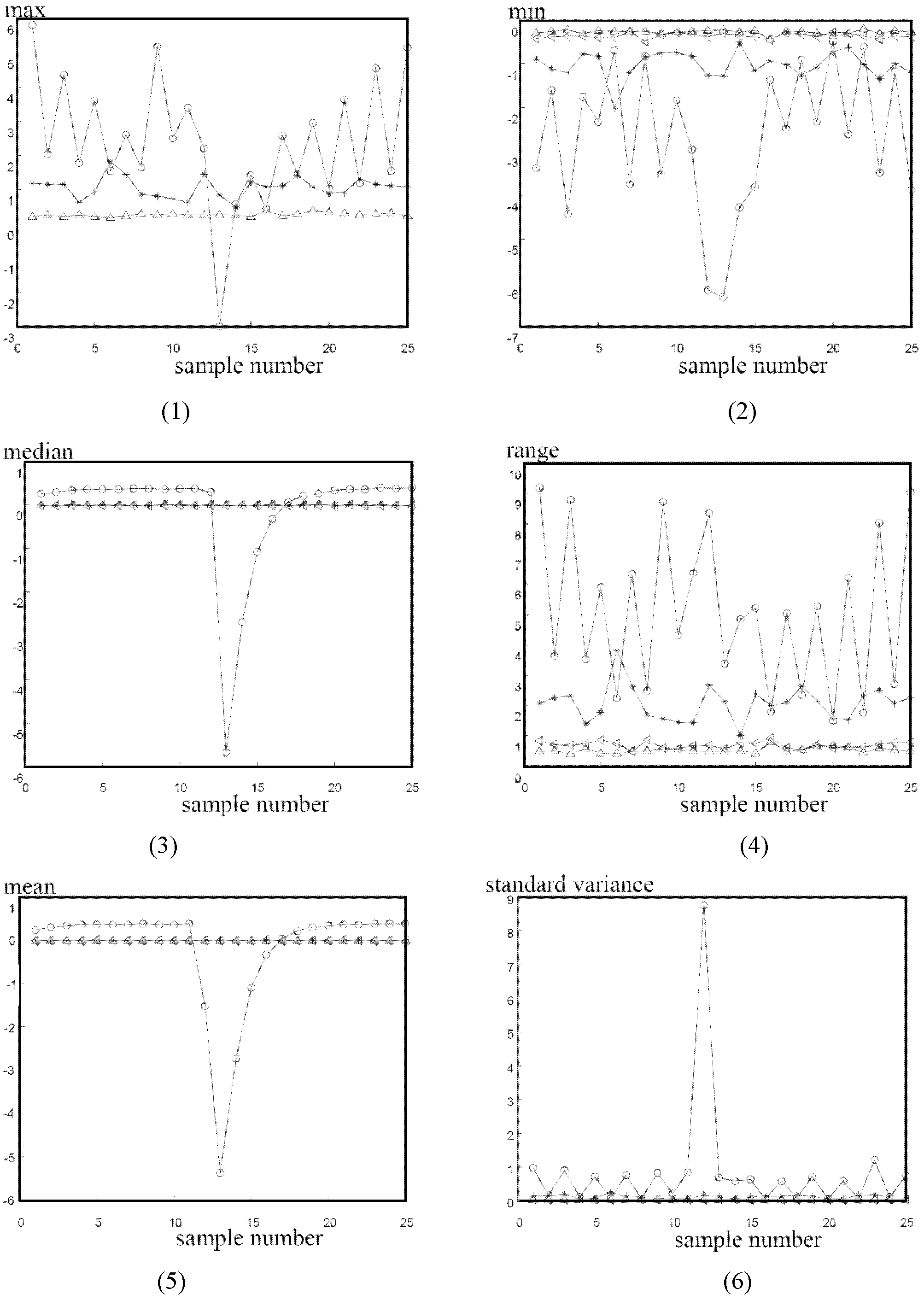

[0039] Such as figure 1 As shown, the present invention consists of five steps: signal collection, feature extraction, establishment of weak classifiers, enhancement of weak classifiers, and realization of multivariate classifiers. First, the time domain signal is collected through the fault test platform, and then the characteristics of the signal are extracted by using statistical methods, and the weak classifier is established by the GentleBoost method, and the weak classifier is enhanced to realize a strong classifier of binary classification, and finally, multiple binary classifiers are used A pairwise combination of the multivariate classifier can be used to identify and classify a variety of fault signals. In the present invention, the running state of the rolling bearing of the aircraft generator is divided into normal state, inner ring damage, rolling element damage and outer ring damage. Therefore, the present invention performs fault identification and classificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com