Device for measuring segregation resistance and bleeding of fresh concrete

A measuring device and concrete technology, which is applied in the field of civil engineering, can solve the problems that the anti-segregation and bleeding performance of fresh concrete cannot be realized at the same time, and can achieve the effect of short measurement time and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

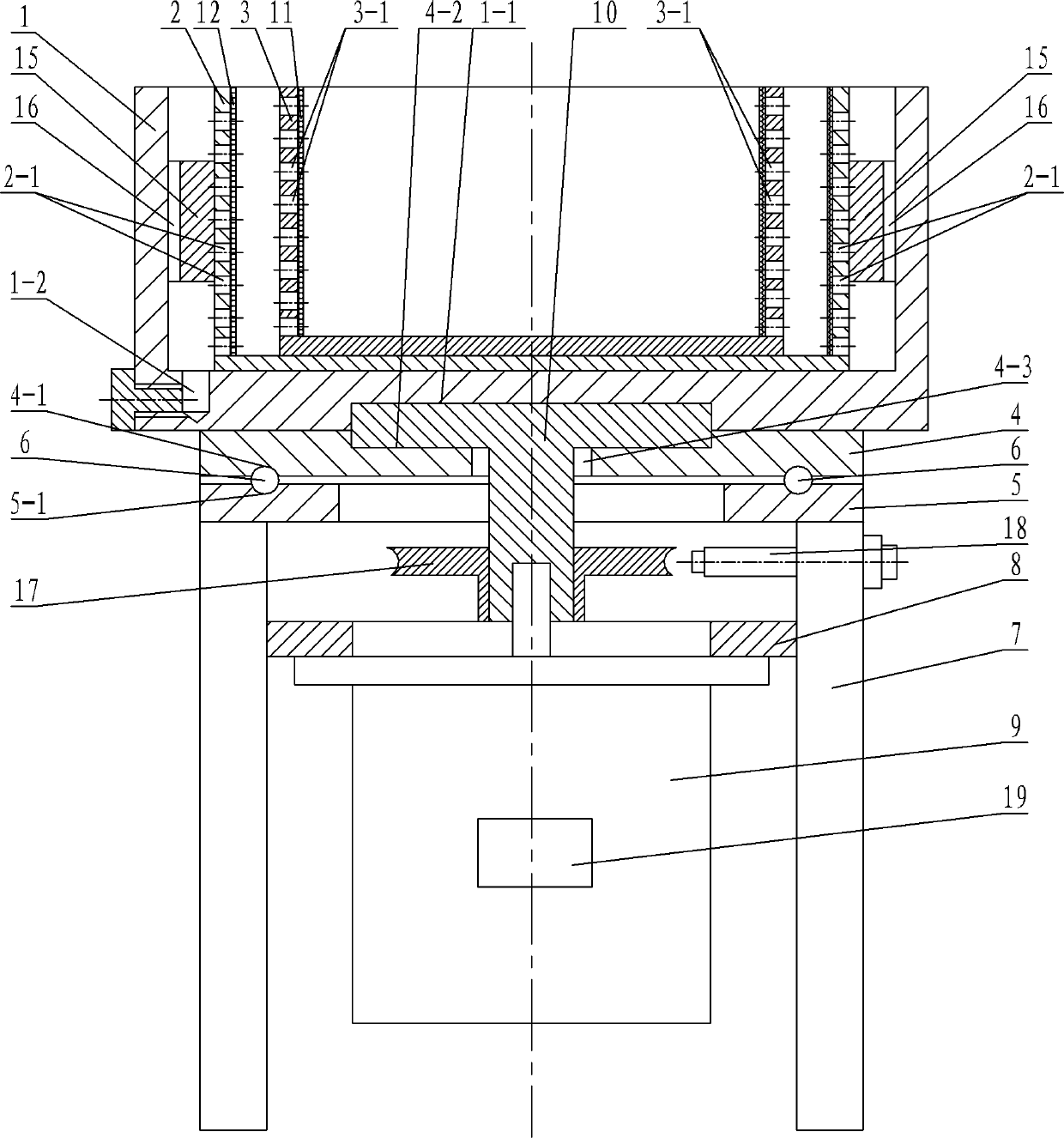

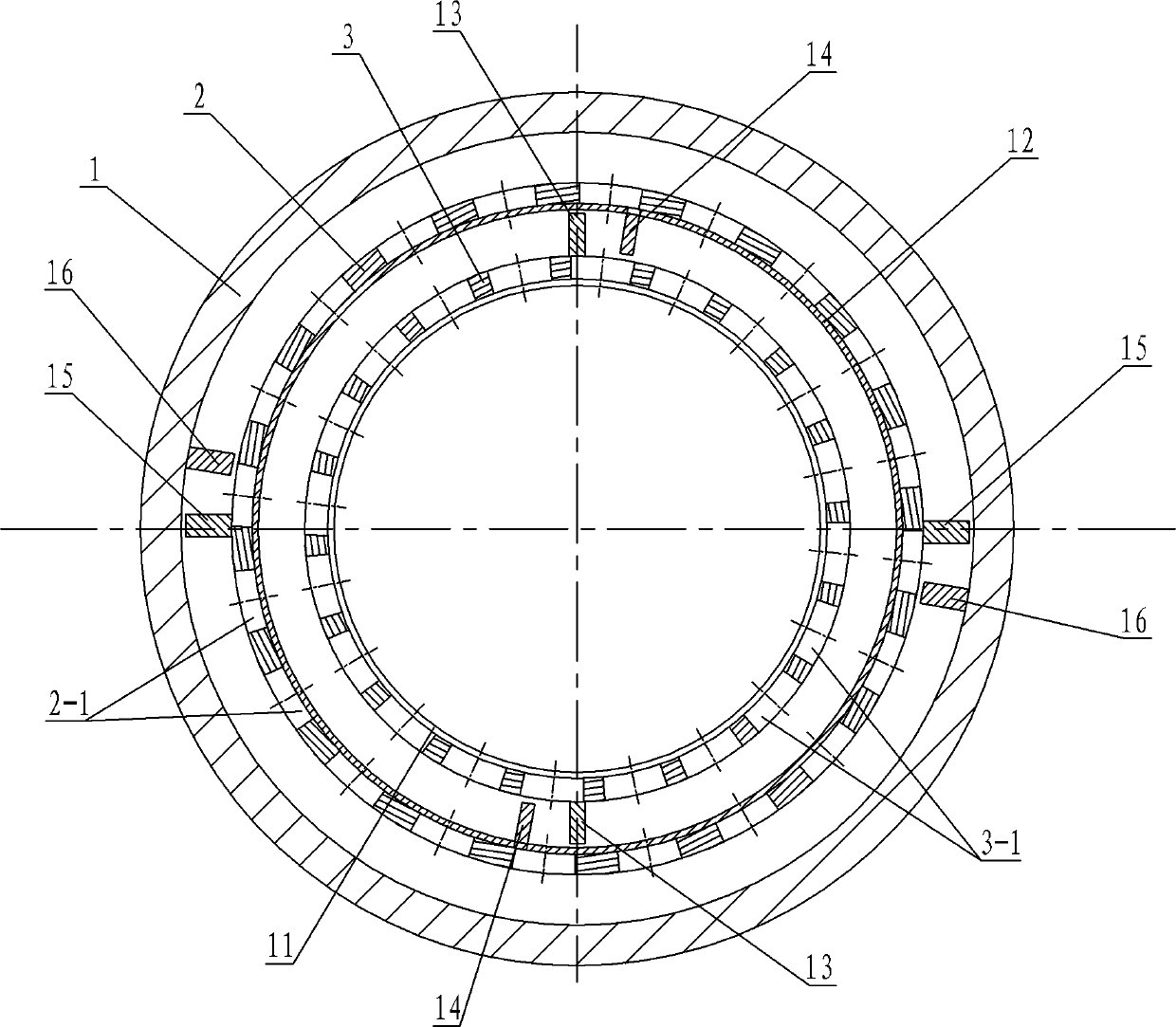

[0012] Specific implementation mode 1: Combination figure 1 with figure 2 To illustrate this embodiment, the device for measuring anti-segregation and bleeding of fresh concrete in this embodiment includes an outer cylinder 1, a middle cylinder 2, an inner cylinder 3, a turntable 4, a chassis 5, a support 7, a ring steel plate 8, a motor 9, T-shaped coupling 10, first metal mesh 11, second metal mesh 12, a plurality of balls 6, at least two first ribs 13 and second ribs 14, which have the same number as the first ribs 13, at least two The third rib 15 and the fourth rib 16 with the same number as the third rib 15;

[0013] The outer cylinder 1 is sleeved outside the middle cylinder 2, the bottom plate of the middle cylinder 2 is in contact with the bottom plate of the outer cylinder 1, the middle cylinder 2 is sleeved outside the inner cylinder 3, and the bottom plate of the inner cylinder 3 is in contact with the bottom plate of the middle cylinder 2. And the outer cylinder 1,...

specific Embodiment approach 2

[0018] Specific implementation manner two: combination figure 2 To illustrate this embodiment, the gap between the outer end surface of the first rib 13 and the second metal mesh 12 of this embodiment, the gap between the inner end surface of the second rib 14 and the outer surface of the annular side wall of the inner cylinder 3, The gap between the outer end surface of the three ribs 15 and the inner surface of the annular side wall of the outer cylinder 1, the gap between the inner end surface of the fourth rib 16 and the outer surface of the annular side wall of the middle cylinder 2, and the gap value is 0.5 mm . This arrangement better guarantees the concentricity of the inner cylinder 3, the middle cylinder 2 and the outer cylinder 1 during the rotation. The other composition and connection relationship are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 To describe this embodiment, the hole diameter of the first through hole 3-1 is 8 mm and the hole diameter of the second through hole 2-1 is 5 mm, and the center distance between two adjacent holes is 10 mm. This setting facilitates the passage of water in the cement mortar. Other components and connection relationships are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com