Method for evaluating flavor stability of beer

A technology of beer flavor and evaluation method, which is applied in measurement devices, instruments, scientific instruments, etc., can solve the problem of inaccurate judgment results, and achieve the effect of making up for subjective and unquantifiable defects and avoiding one-sidedness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

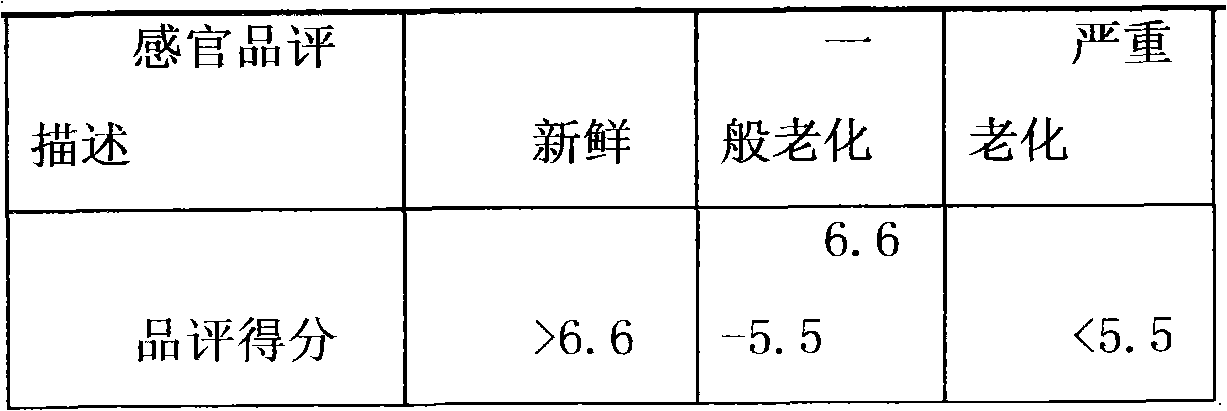

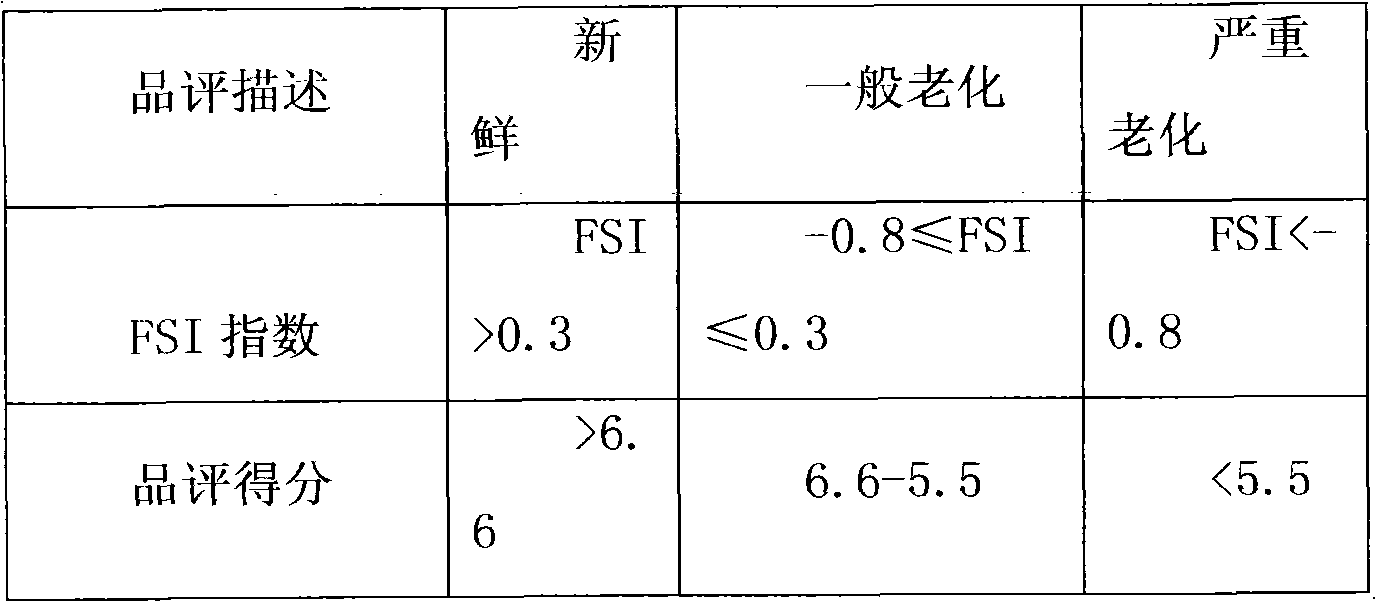

Embodiment 1

[0035] Finished beer A, a pure draft beer purchased in the market, the corresponding detection indicators are: free radical value A = 28745, LagTime value B = 123min, furfural concentration ppb value C = 60.45ppb, 3-methylthiopropanal concentration ppb Value D = 2.09 ppb, phenylacetaldehyde concentration ppb value E = 6.59 ppb, trans-2 nonenal concentration ppb value F = 0.10 ppb. The calculated FSI index is 0.403, which is judged as fresh according to the evaluation system. The average sensory evaluation score of this sample is 7.2 points, which is in the range of fresh beer sensory evaluation scores. The evaluation results of FSI index were consistent with those of sensory evaluation.

Embodiment 2

[0037] Finished beer B, an ordinary beer purchased in the market, the corresponding indicators for detection are: free radical value A = 28860, LagTime value B = 105min, furfural concentration ppb value C = 76.30ppb, 3-methylthiopropanal concentration ppb value D=4.95ppb, phenylacetaldehyde concentration ppb value E=30.52ppb, trans-2-nonenal concentration ppb value F=0.17ppb. The calculated FSI index is -0.477, which is judged to be general aging according to the evaluation system. The average sensory evaluation score of this sample is 6.25 points, which is in the range of general aged beer sensory evaluation scores. The evaluation results of FSI index were consistent with those of sensory evaluation.

Embodiment 3

[0039] Finished beer C, an ordinary beer purchased in the market, the corresponding detection indicators are: free radical value A = 84121, LagTime value B = 24min, furfural concentration ppb value C = 35652ppb, 3-methylthiopropanal concentration ppb value D =18.60ppb, the ppb value of phenylacetaldehyde concentration E=125.25ppb, the ppb value of trans-2-nonenal concentration F=0.31ppb. The calculated FSI index is -1.49, which is judged to be severely aged according to the evaluation system. The average sensory evaluation score of this sample is 5.30 points, which is in the range of severe aging beer sensory evaluation scores. The evaluation results of FSI index were consistent with those of sensory evaluation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com