Cage for handling or storing goods

A technology for goods and rails, applied in the field of cages for bundling items, can solve problems such as redundant effort or space, and achieve the effects of increasing occupational safety, smooth operation, and improving strength properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

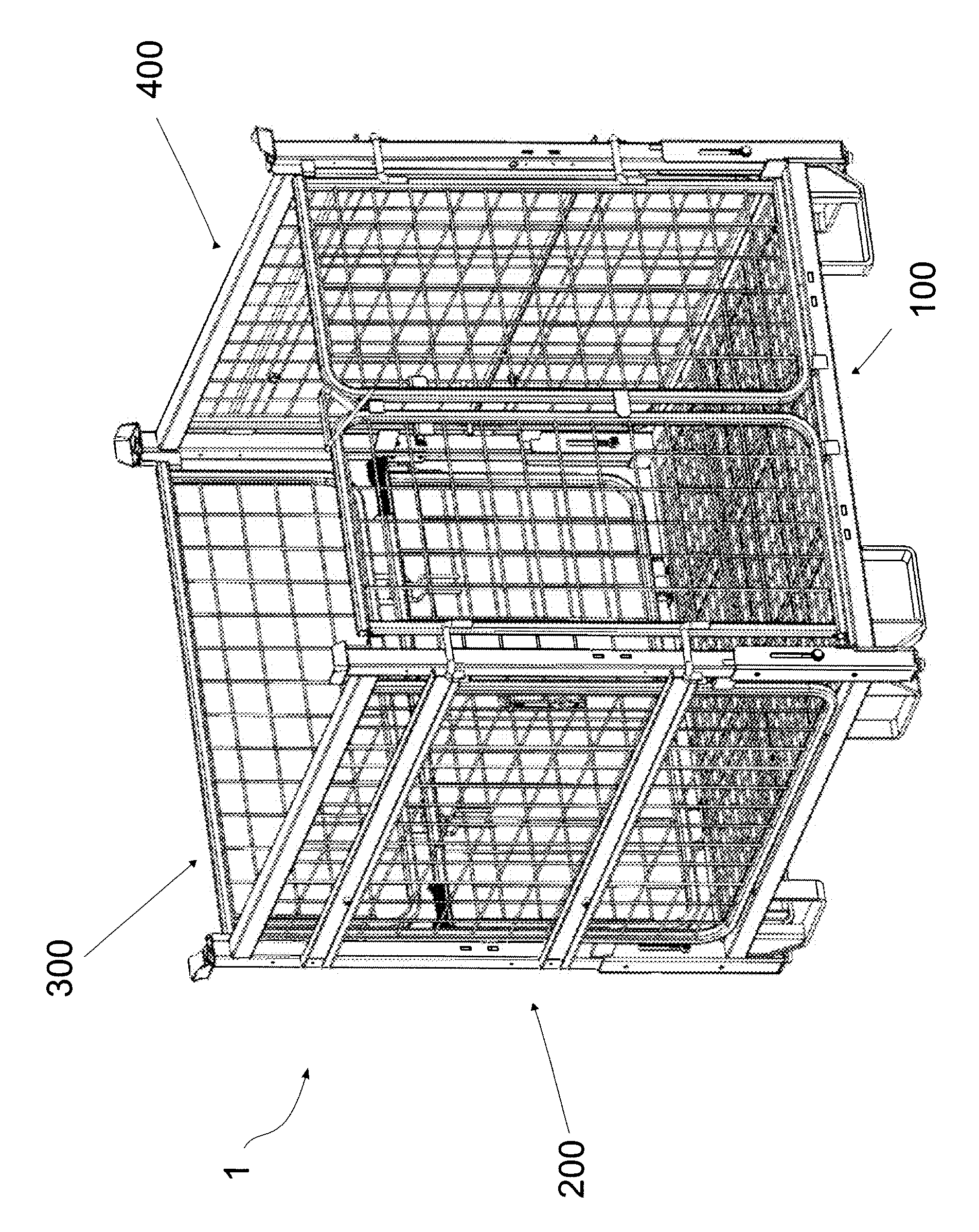

[0027] Such as figure 1 As shown, the cage 1 according to the invention has the shape of a columnar crate. The dimensions of the cage 1 advantageously comply with industry standards, such as European dimensions or UK dimensions, in order to occupy local transport equipment as efficiently as possible. Of course, cage 1 therefore has six surfaces. According to one embodiment, one of the six surfaces, referred to herein as the front end 100 , is used for loading and unloading the cage 1 . Within the scope of the invention, the cage 1 may have more than one surface for loading.

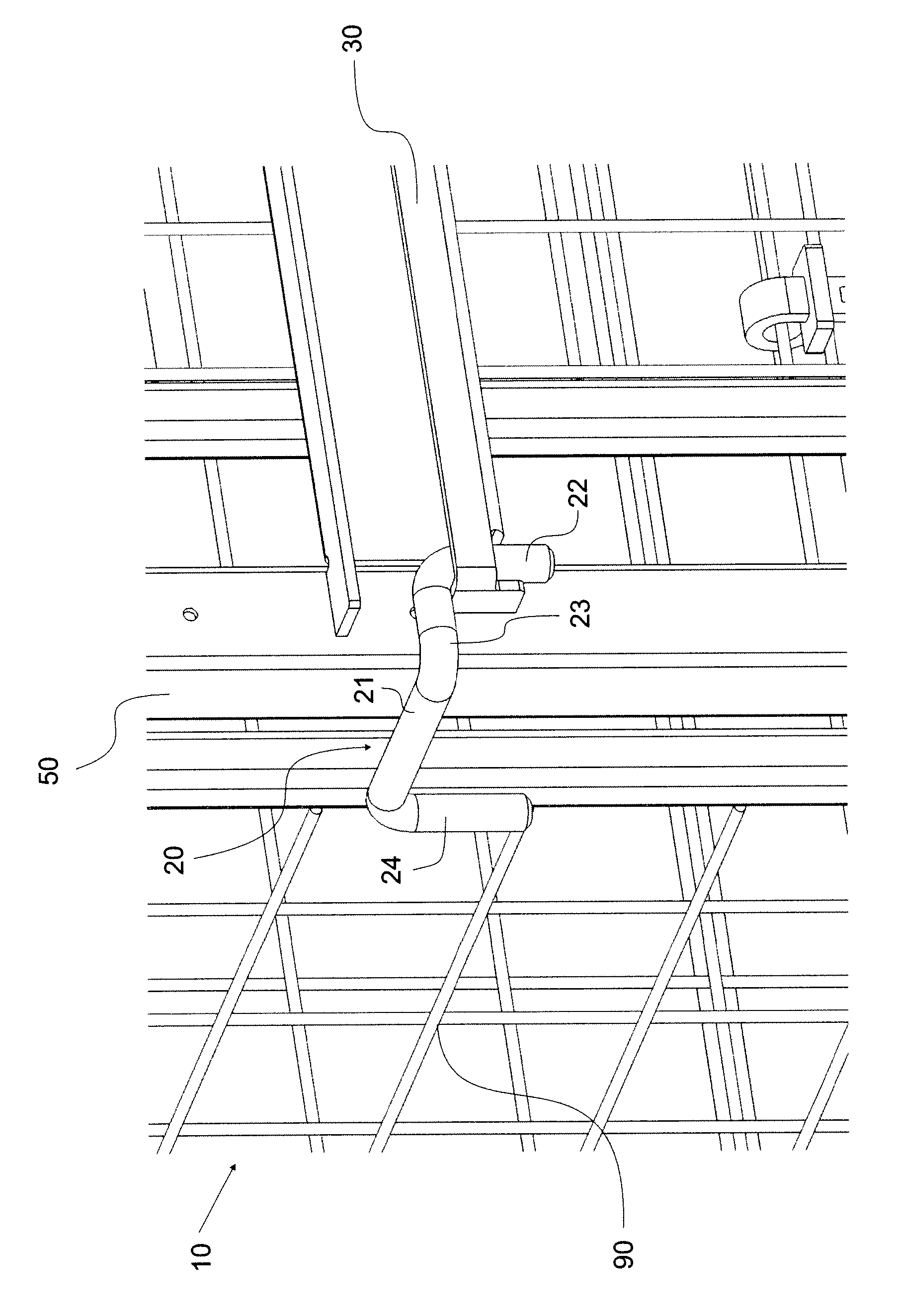

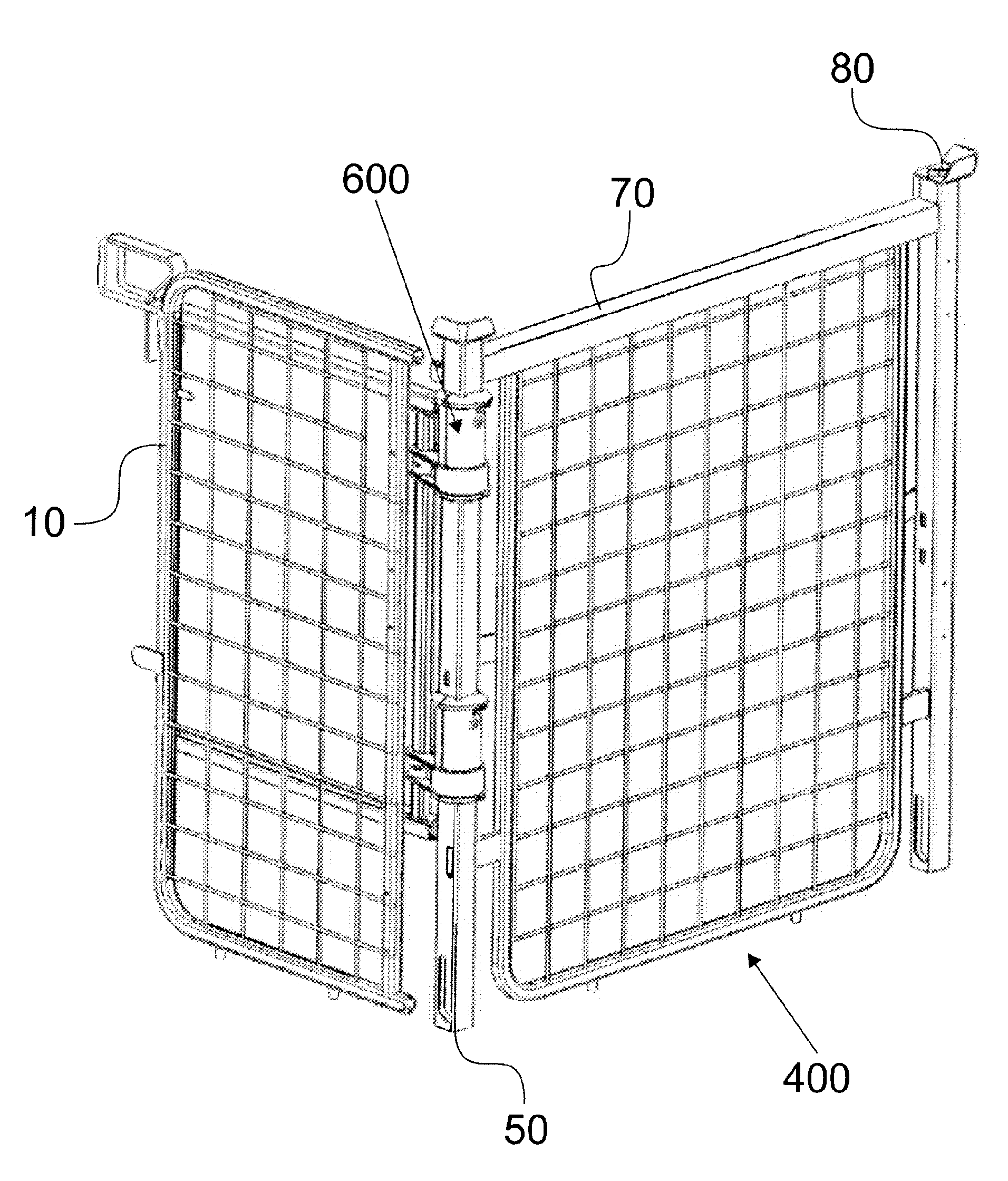

[0028] Since the cage 1 is cylindrical, it has two lateral walls, namely a first lateral wall 200 and a second lateral wall 400 , situated on either side of and perpendicular to the front end 100 . The transverse walls 200, 400 comprise vertical frame members 50 and horizontal frame members 70 which are connected together to form a rectangular frame, as figure 2 shown. The frame is provided with a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com