Vibration exciter

A vibrator and eccentric block technology, which is applied in chemical instruments and methods, fluid and solid separation using vibration, etc., can solve the problem of oil leakage at the vibrator shaft and bearing seal, poor sealing effect and working conditions, and inconvenient disassembly and assembly. Convenience and other issues, to achieve the effect of improving oil leakage, improving efficiency and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

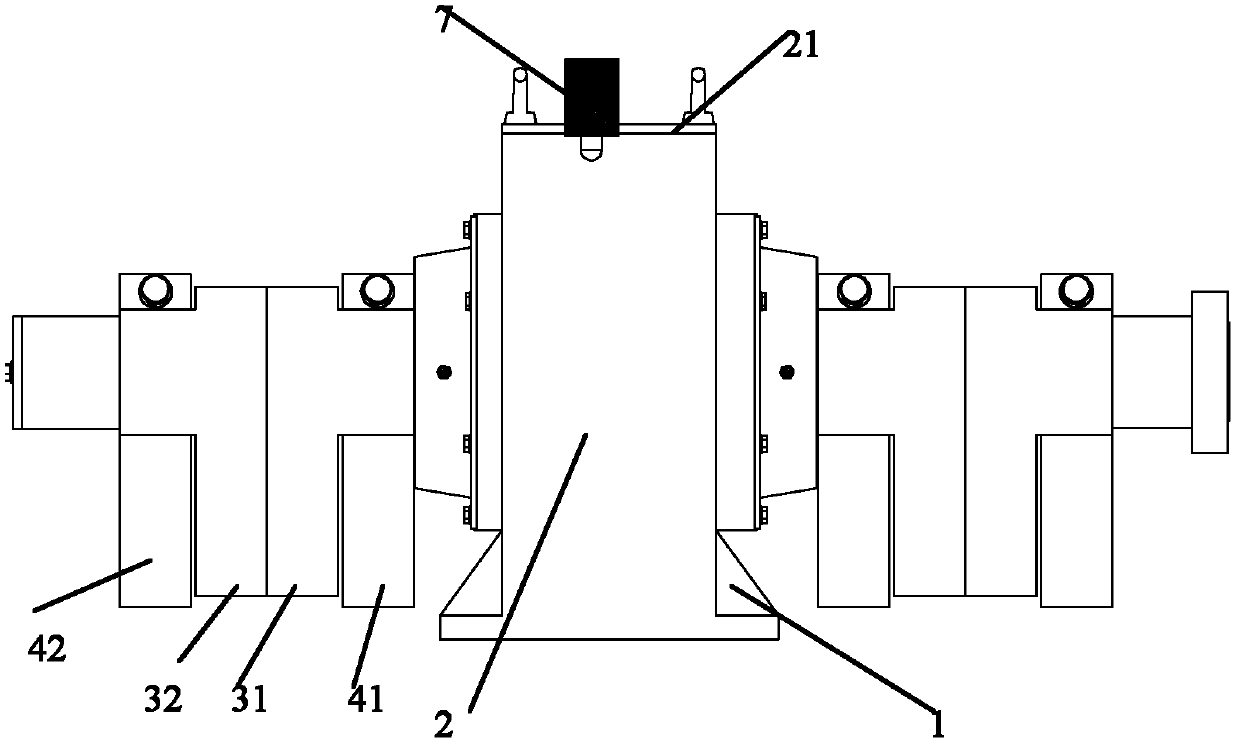

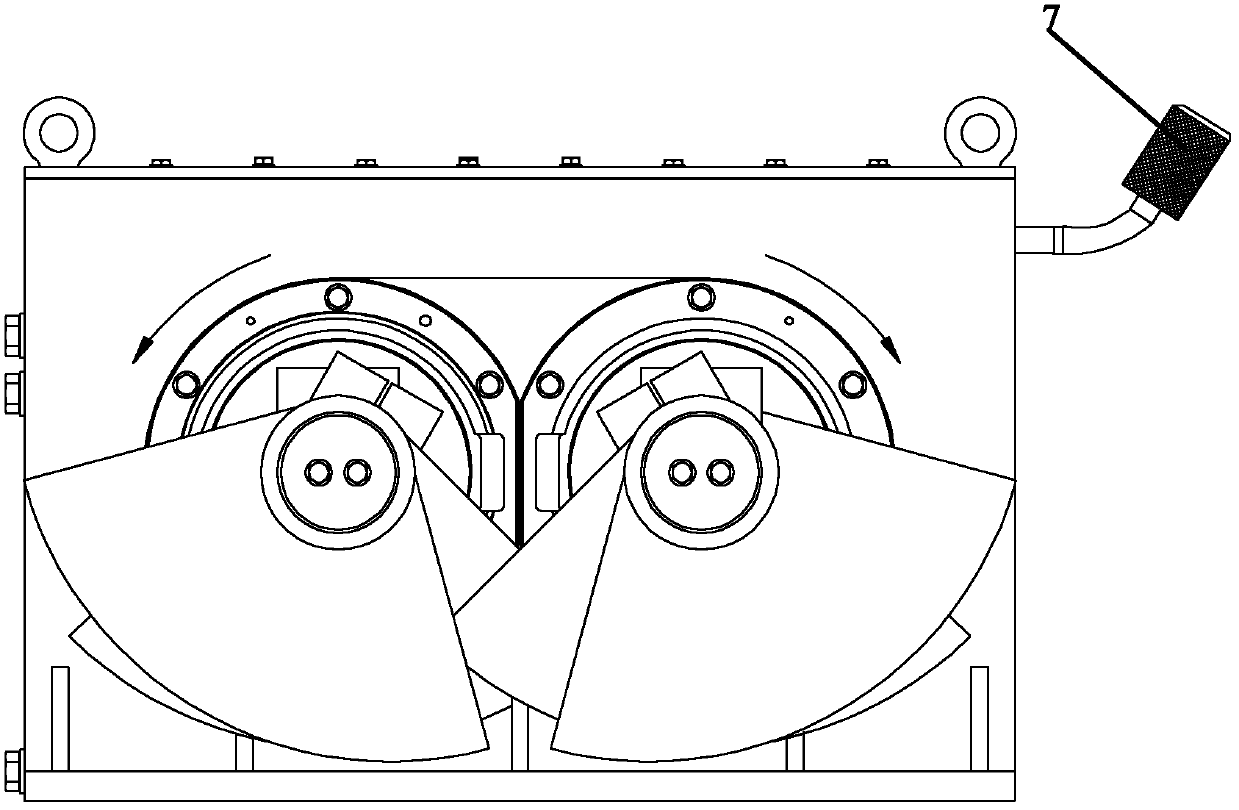

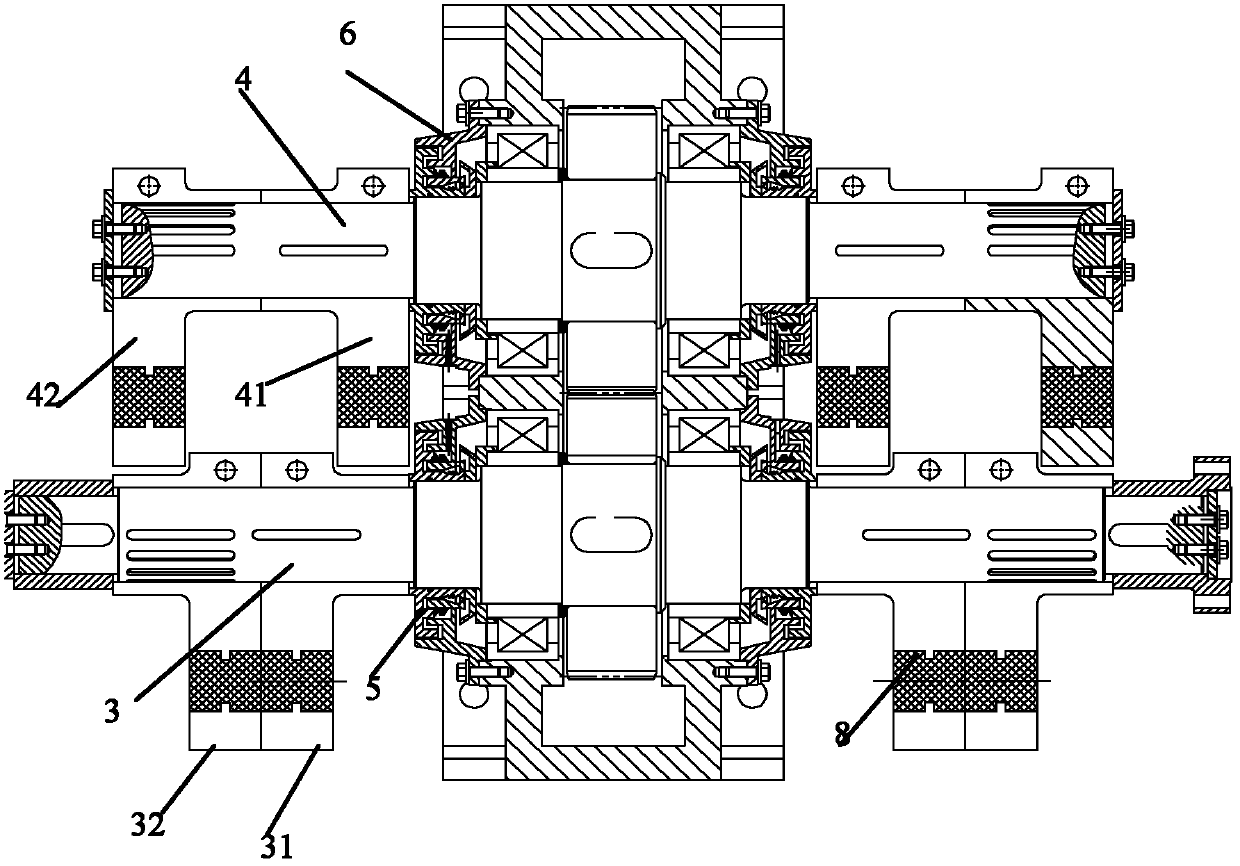

[0020] Such as Figure 1-3 As shown, the exciter of the present invention includes a base 1; a rectangular box 2 fixed on the top of the base 1, and an upper cover 20 is fixedly connected to the upper part of the box 2, and the upper cover 20 and the box form a The sealed cavity 21 is provided with two pairs of circular through holes 22 correspondingly on both sides of the box body, the driving shaft 3 and the driven shaft 4 respectively pass through the box body and both ends are located outside the box body , Bearings and sealing structures are respectively arranged between the driving shaft, the driven shaft and the box body.

[0021] Such as Figure 1-3 As shown, first eccentric block structures are respectively symmetrically arranged outside the casings at both ends of the drive shaft 3, and the first eccentric block structures are two ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com