Multifunctional single frame emulsion system of reversible cold rolling mill and emulsion operating method of multifunctional single frame emulsion system

An emulsion system and emulsion technology, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve problems affecting production efficiency, rolling mills cannot run, etc., and achieve the effect of continuous production and cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

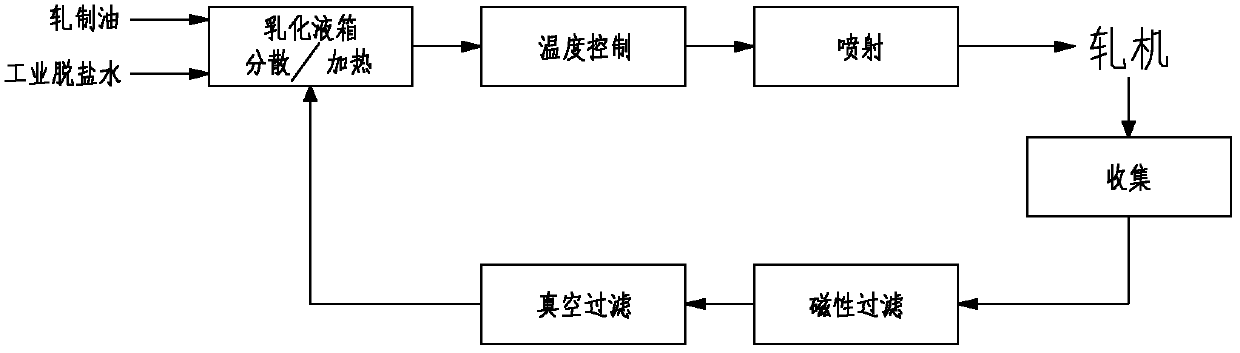

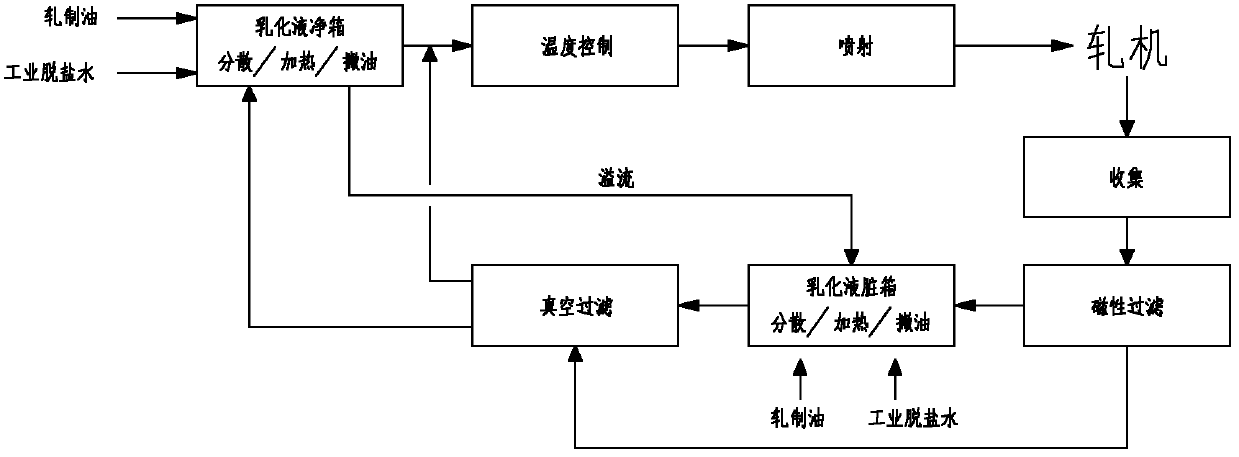

[0041] A multi-functional single-stand reversible cold rolling mill emulsion system, including: sequentially connected emulsion tank-temperature control device-spray device-rolling mill-collection device-magnetic filter equipment-vacuum filter equipment-emulsion tank, the emulsifier The liquid tank is fed with rolling oil and industrial desalted water, dispersed and heated in the emulsion tank, and an emulsion dirty tank is set between the magnetic filter equipment and the vacuum filter equipment, and the emulsion dirty tank is separated It communicates with and accepts the overflow liquid from the emulsion tank, and the vacuum filter equipment is connected to the connecting pipeline of the emulsion tank-temperature control device at the same time, and the emulsion dirty tank is fed with rolling oil and industrial desalinated water.

[0042] According to this embodiment, the emulsion tank is an emulsion clean tank. According to this embodiment, the overall operation method flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com