Helical spring device with functions of damping and silencing

A helical spring and damping technology, which is applied in the field of vibrating screening machinery, can solve the problems of large resonance amplitude, etc., and achieve the effects of reducing noise, improving overall performance, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

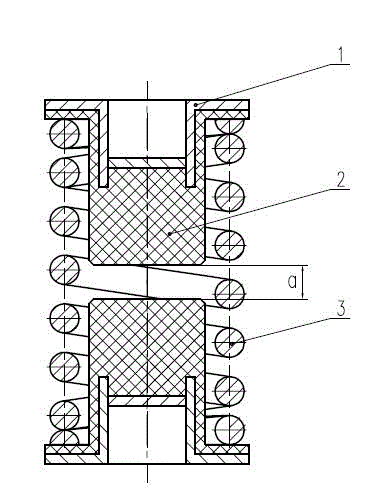

[0007] An embodiment of the present invention is described below in conjunction with the accompanying drawings. A rubber seat spring 2 inlaid with a metal skeleton 1 is respectively installed at the two ends of the metal coil spring 3. The profile of the rubber seat spring 2 is made up of two stepped cylindrical surfaces, wherein The stepped end face of the short cylindrical surface is in contact with the end face of the metal helical spring 3 , and the long cylindrical surface is inserted in the hole of the metal helical spring 3 . When the coil spring device with damping and noise reduction is installed on the vibrating screen, there is a gap a in the axial direction between the rubber seat springs 2 at both ends of the metal coil spring 3, and the gap a is set according to the vibration quality and amplitude of the vibrating screen 15mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com