Punching die for two-hole cover plate of capacitor

A hole cover and capacitor technology, which is applied in the direction of perforation tools, manufacturing tools, metal processing equipment, etc., can solve the problems of unreasonable stamping die structure, mold damage, low stamping quality of two hole cover plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

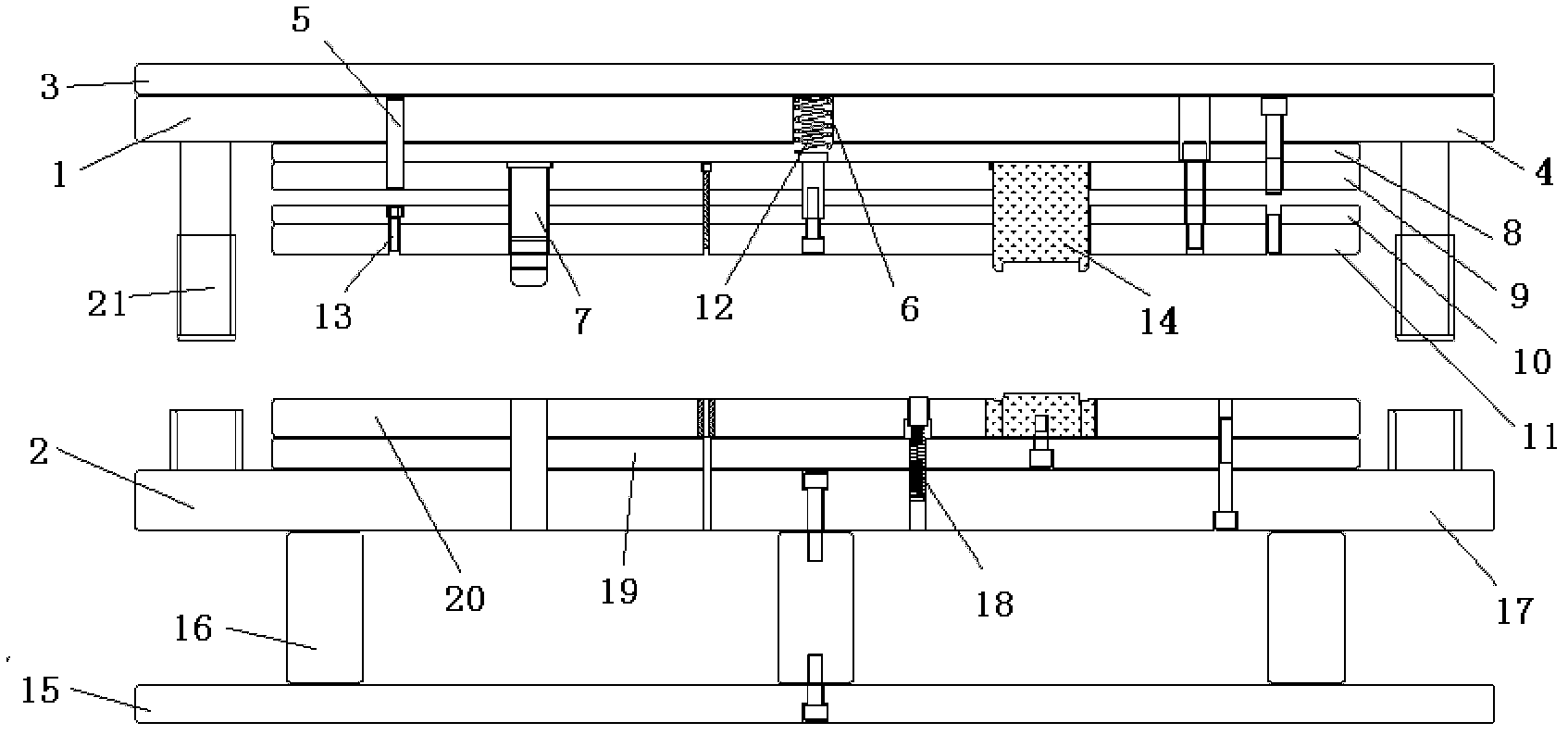

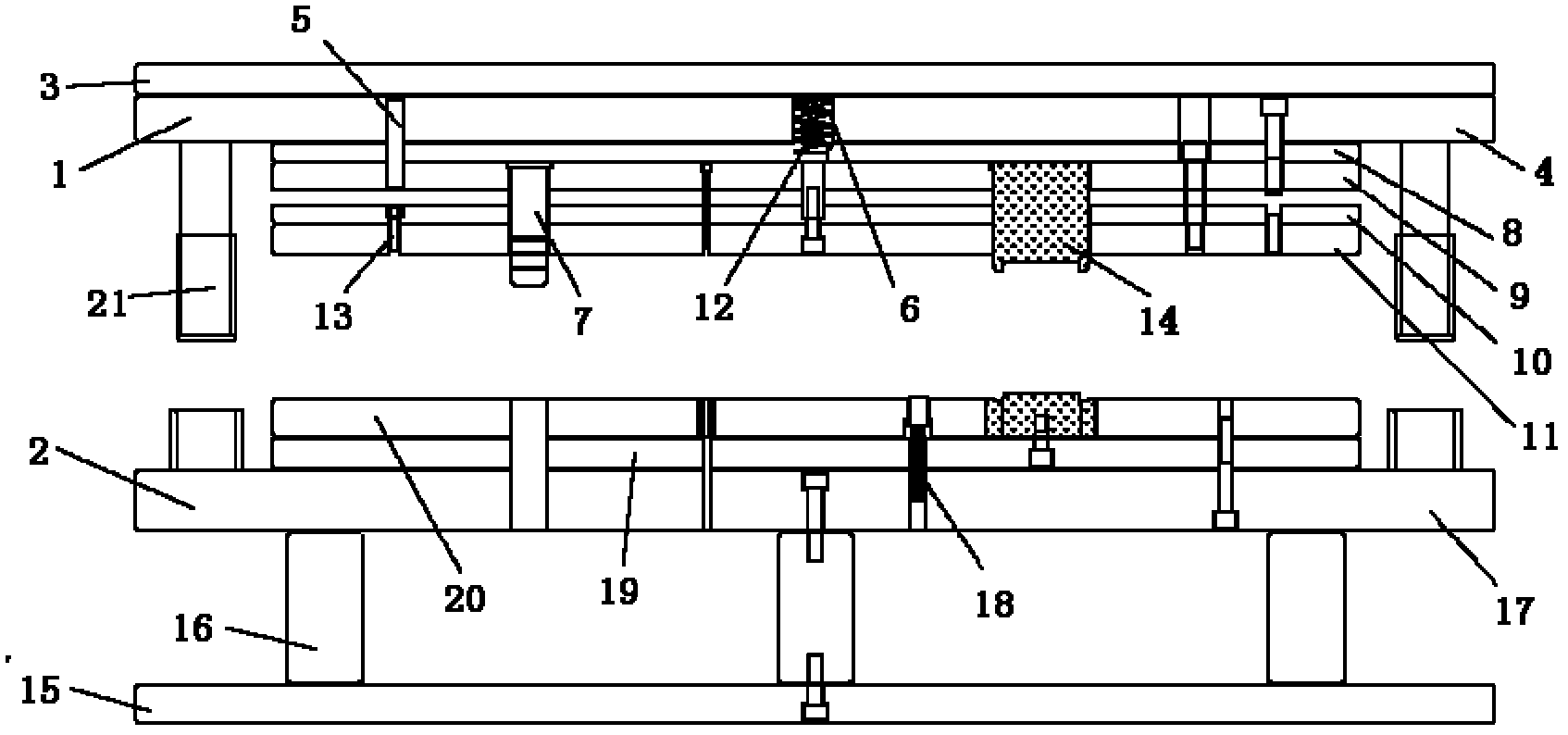

[0010] Referring to the accompanying drawings, a punching die for a cover plate with two holes for a capacitor includes an upper mold 1 and a lower mold 2, the upper mold 1 includes an upper pressing plate 3, and the lower layer of the upper pressing plate 3 is provided with an upper mold base 4, so The upper mold base 4 is provided with a positioning pin 5, a spring hole 6 and an inner guide column 7, and the upper mold base 4 is provided with an upper backing plate 8, an upper splint 9, a stop plate 10 and a stripper plate 11 in sequence. , a spring 12 is installed in the spring hole 6, and the spring 12 is supported on the upper splint 9, the stop plate 10 and the stripping plate 11 are fixed as one by bolts 13, and an inner splint 9 is fixedly installed on the upper splint 9. Guide post 7, the inner guide post 7 passes through the stop plate 10 and the stripper plate 11, the upper clamping plate 9, the stop plate 10 and the stripper plate 11 can slide up and down along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com