Pneumatic punching machine

A technology of pneumatic punching machines and punching machines, which is applied in the direction of punching machines, presses, manufacturing tools, etc., can solve the problem of crushing the operator, and achieve the effects of high safety, adjustable orientation, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Specific implementation plan

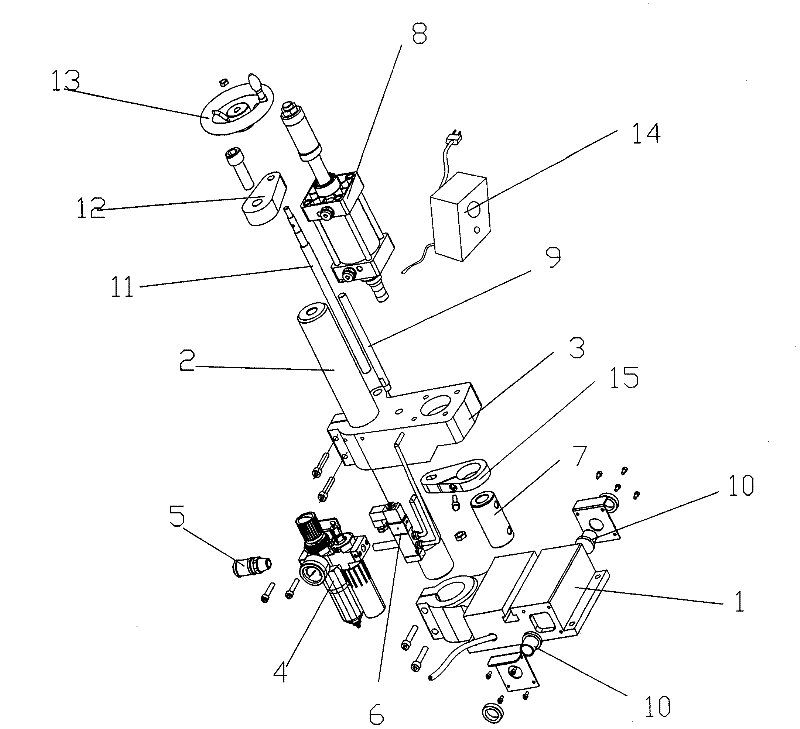

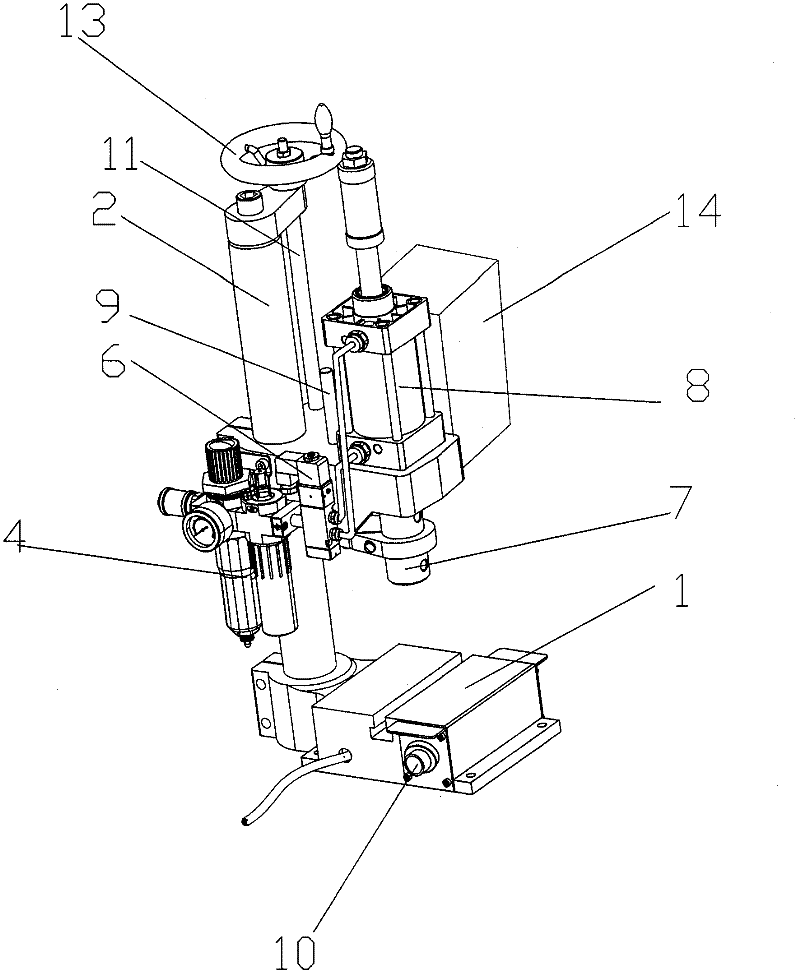

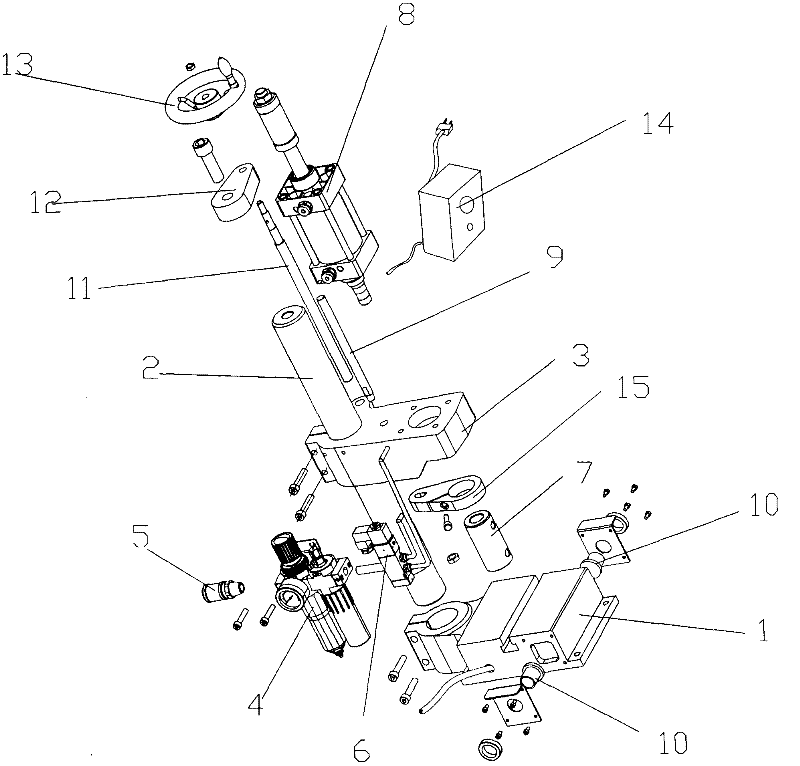

[0010] Reference attached Figure 1-2 And specific embodiments to illustrate the present invention.

[0011] A pneumatic punching machine, comprising a base 1 used as a workbench and supporting and stabilizing a base 1, a main shaft 2 with the bottom embedded in the base, and a top frame punch that is sleeved on the main shaft and can perform a punching action. The top frame punch includes a top frame 3. One side of the top frame is connected with the double body 4, the two ends of the double body are respectively connected with the hand slide valve 5 and the solenoid valve 6, and the double shaft adjustable cylinder 8 with the punch 7 is connected on the top frame. A piston rod and a piston are arranged in the adjusting cylinder 8. A guide rod 9 is provided on the top frame to prevent the piston rod from rotating when the piston rod of the cylinder moves up and down. There are buttons on both sides of the base that need to be opened at the sa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap