Fixed battery quick changing mechanism for electric vehicle

A technology for quick replacement of electric vehicles and batteries, applied in the direction of electric power devices, power devices, vehicle components, etc., can solve the problems of inconvenient installation of battery frames, large space, and inconvenient battery replacement, so as to facilitate battery replacement, improve stability, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

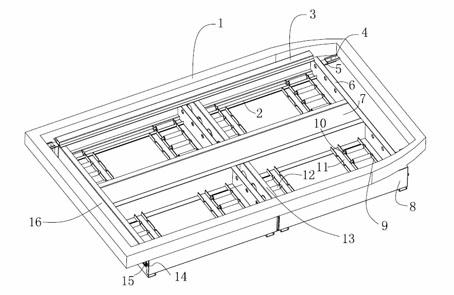

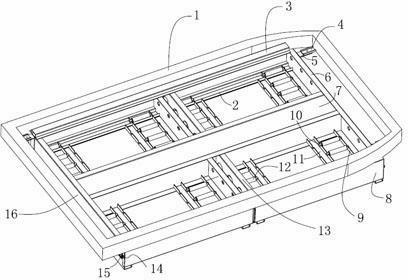

[0020] Embodiment: a kind of stationary electric vehicle battery frame (see attached figure 1 ), including the battery frame connected to the chassis frame 1 of the electric vehicle. The battery frame includes a front plate 6, a rear plate 16, an upper longitudinal beam 3, a lower longitudinal beam 2, a cross beam 13 and a middle beam 7; the front plate is parallel to the rear plate, and two middle Two beams are vertically fixed in the middle of the two middle beams, two upper and lower longitudinal beams are respectively connected between the upper and lower sides of the front plate and the rear plate, and the ends of the beams are connected with the upper and lower longitudinal beams The stringers are fixed. The center beam and the cross beam divide the battery frame into four battery accommodation chambers. The front plate and the rear plate are of channel steel structure with opposite notches; the middle beam is of channel steel structure with opposite notches; the cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com