Cover structure of fuel tank

A fuel tank cover, fuel tank technology, applied in gasoline drums, bicycle accessories, transportation and packaging, etc., to achieve the effect of reducing the number of parts, improving productivity, and reducing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, an embodiment will be described with reference to the drawings.

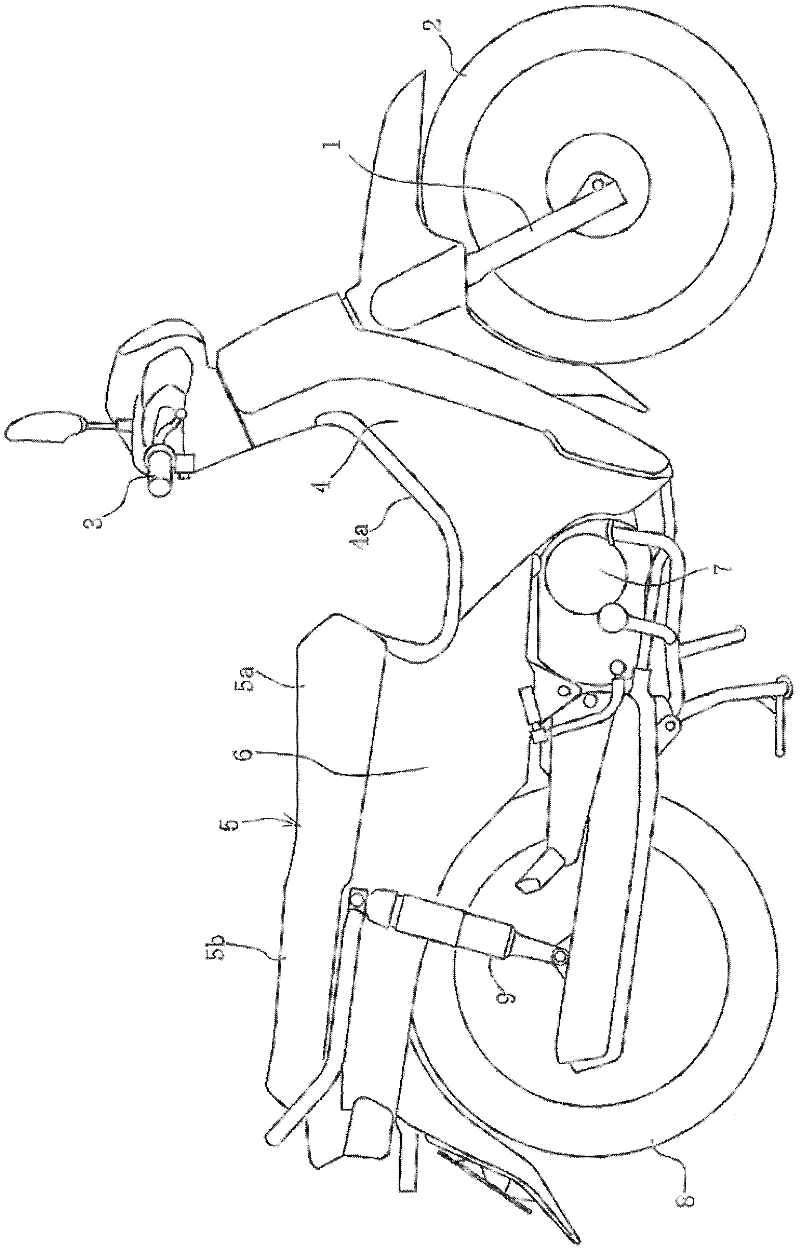

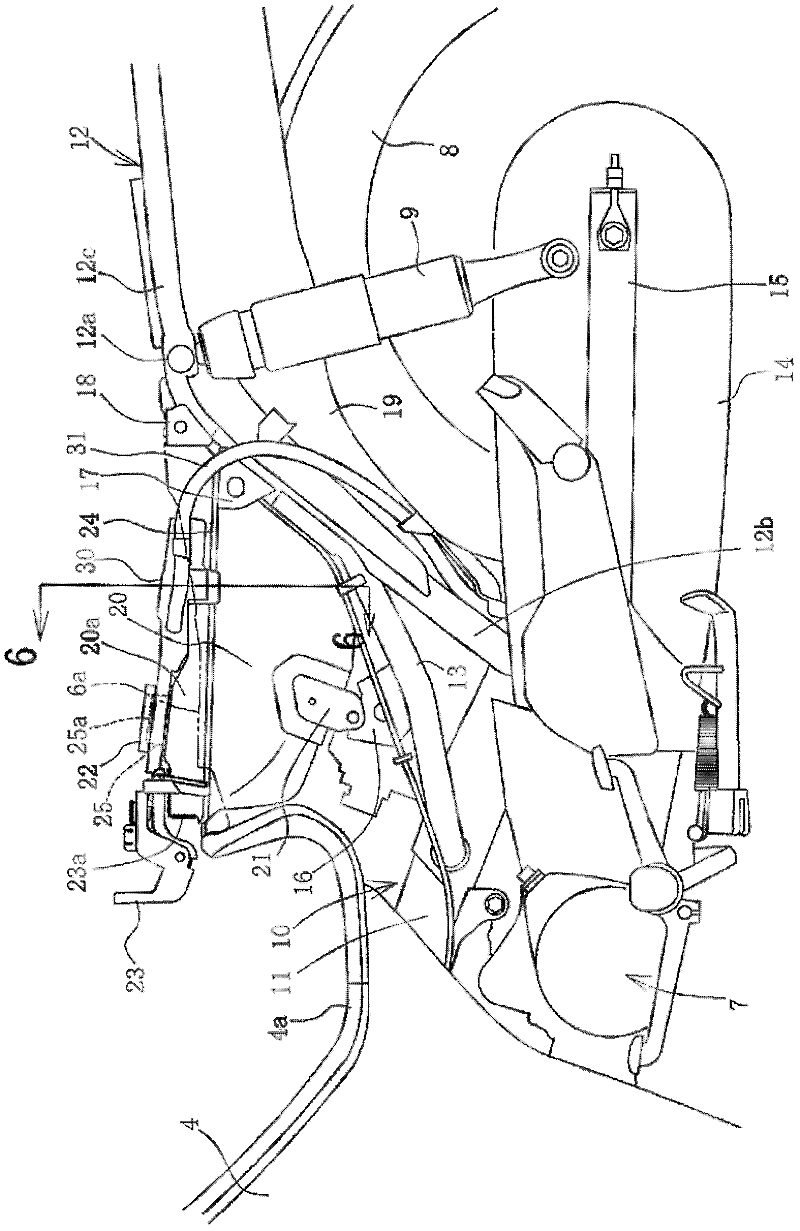

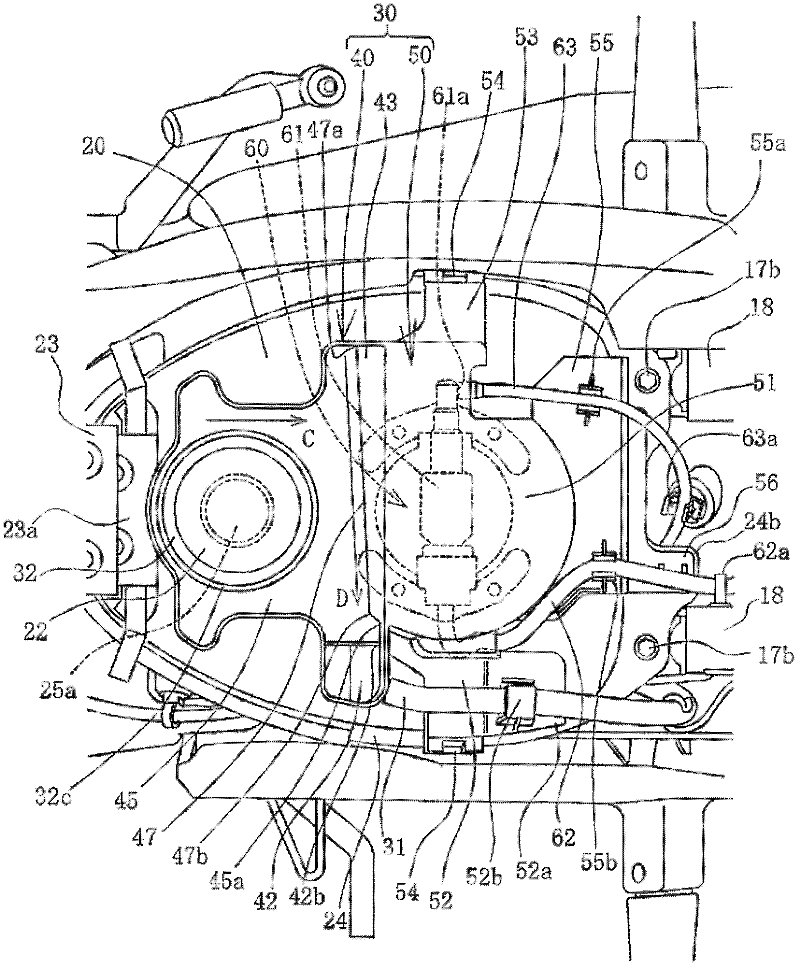

[0049] figure 1 It is a right side view showing the appearance of the motorcycle of this embodiment, figure 2 It is a figure showing the part around the fuel tank on the left side of the vehicle body, omitting the seat and the body cover, image 3 is a top view of the surrounding part of the fuel tank, Figure 4 It is a perspective view of the part around the fuel tank, Figure 5 is the rear view of the part around the fuel tank, Figure 6 yes figure 2 The 6-6 line sectional view.

[0050] First, in figure 1 Among them, at the front of the vehicle body, a front wheel 2 is supported at the lower end of a front fork 1 rotatably supported by a front end portion of a vehicle body frame not shown, and is steered by an upper handlebar 3 .

[0051] The front part of the vehicle body is covered by a front body cover 4, and a seat 5 is disposed behind the handlebar 3 so as to sandwich the sad...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap