Heat-seal packaging equipment and cross-seal cutting device thereof

A cutting device and horizontal sealing technology, which is applied in packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of affecting output, high packaging damage rate, and high equipment replacement cost, so as to prolong the service life and avoid local damage , Increase the effect of the force surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

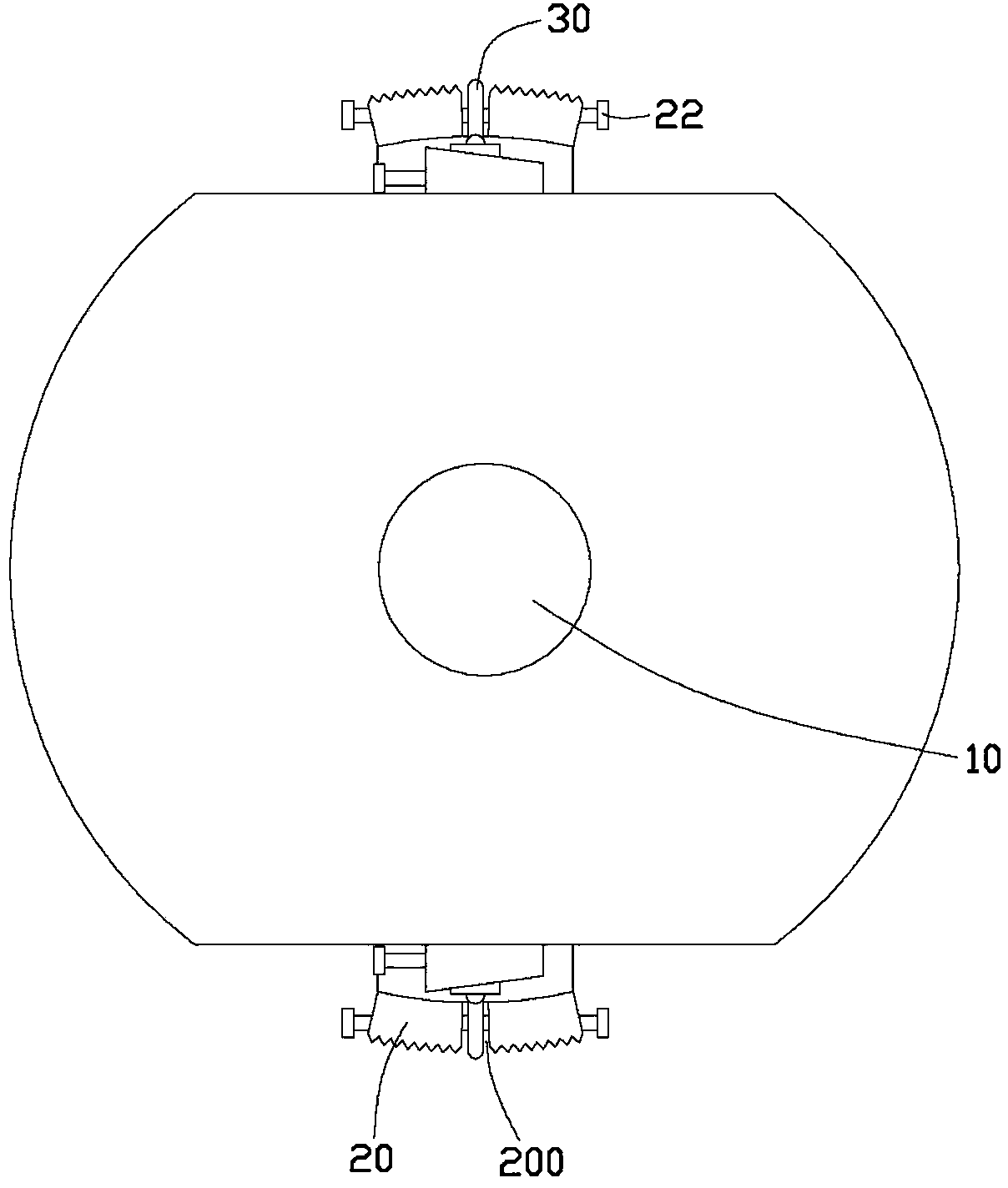

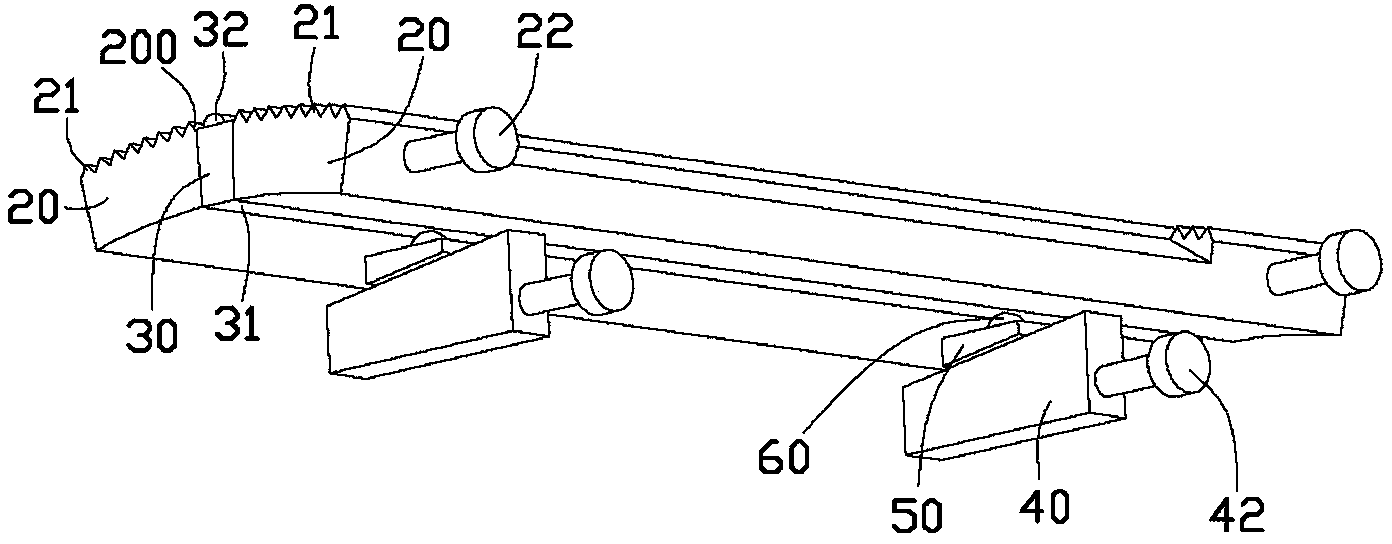

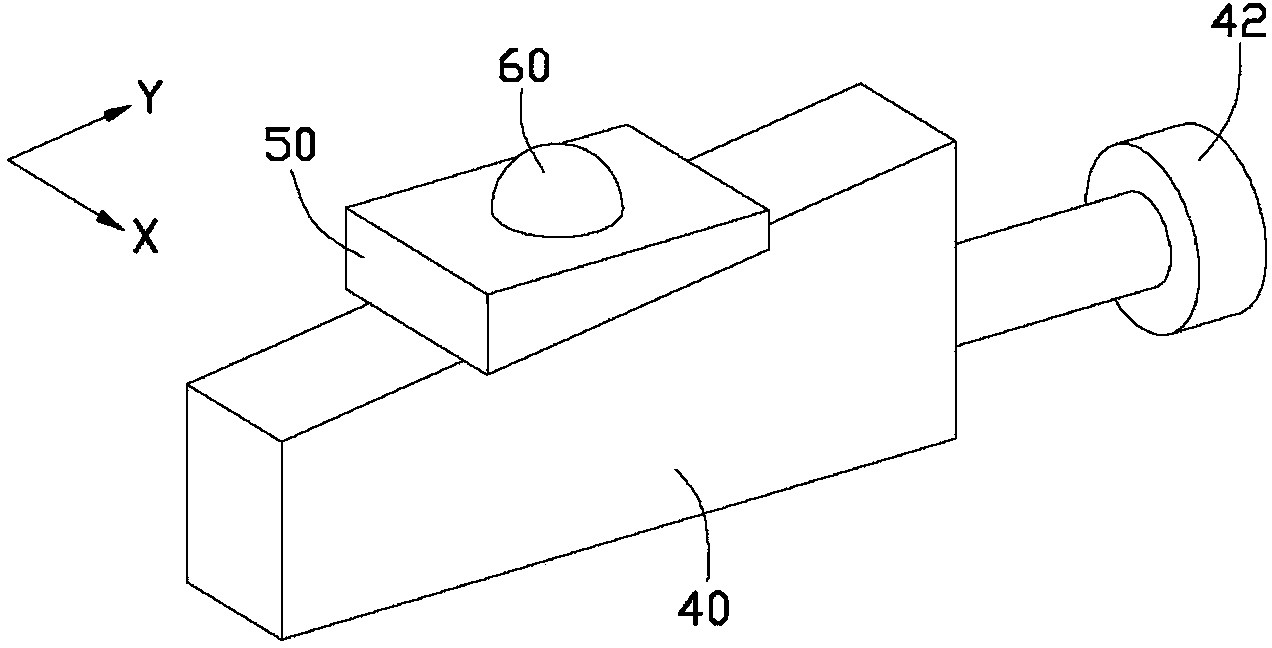

[0027] Please refer to figure 1 , The horizontal sealing and cutting device according to an embodiment of the present invention includes a horizontal sealing shaft 10 , two heat-pressing heads 20 symmetrically arranged on the horizontal sealing shaft 10 , and a cutter 30 arranged on each heat-pressing head 20 .

[0028] The horizontal sealing and cutting device also includes another horizontal sealing shaft 10 not shown in the figure which is arranged in parallel with the horizontal sealing shaft 10 , and a heat-pressing sealing head 20 and a cutting knife 30 are also arranged on the other horizontal sealing shaft 10 . The two horizontal sealing shafts 10 rotate in opposite directions, so that the heat-pressing sealing heads 20 on the two horizontal sealing shafts 10 are docked, so that the packaging materials running between the two horizontal sealing shafts 10 are thermally fused to achieve horizontal sealing , and the cutting knife 30 cuts off the transverse seal from the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com