Full-automatic cigarette conveyance caching device

An automatic cigarette strip and fully automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high manual labor intensity, increased waste rate, and low production efficiency, so as to reduce labor intensity, improve production efficiency, and automatically The effect of storage and release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

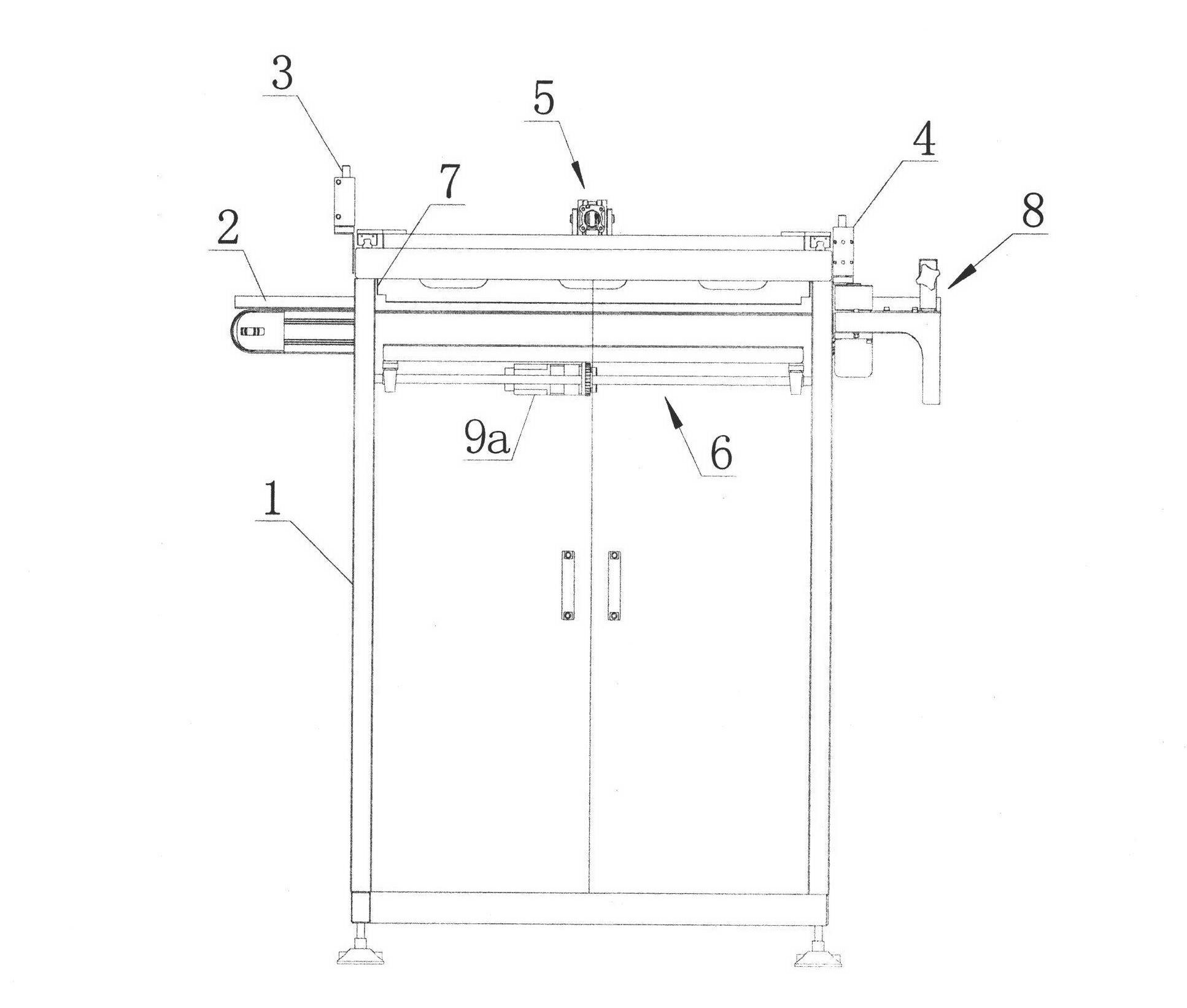

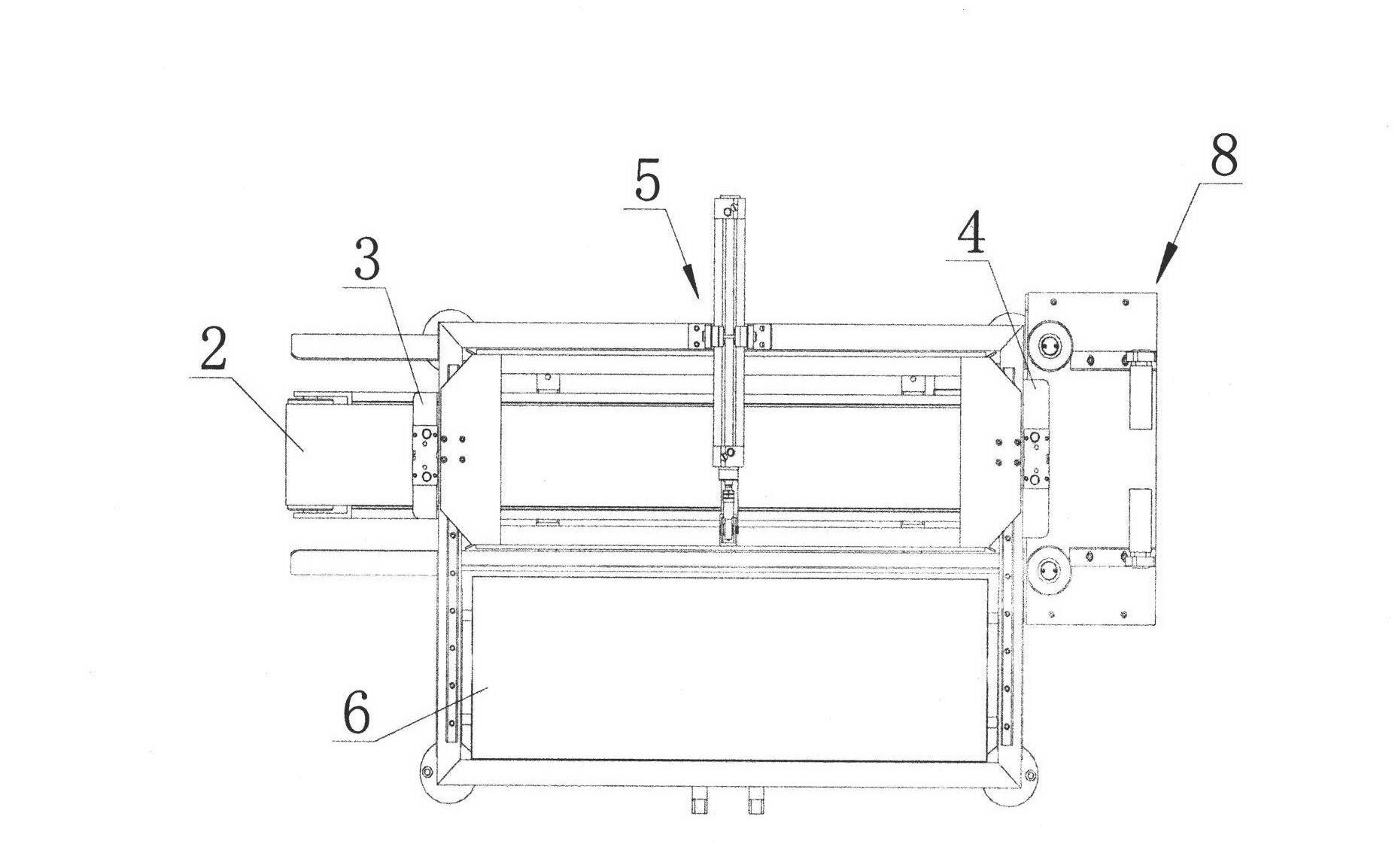

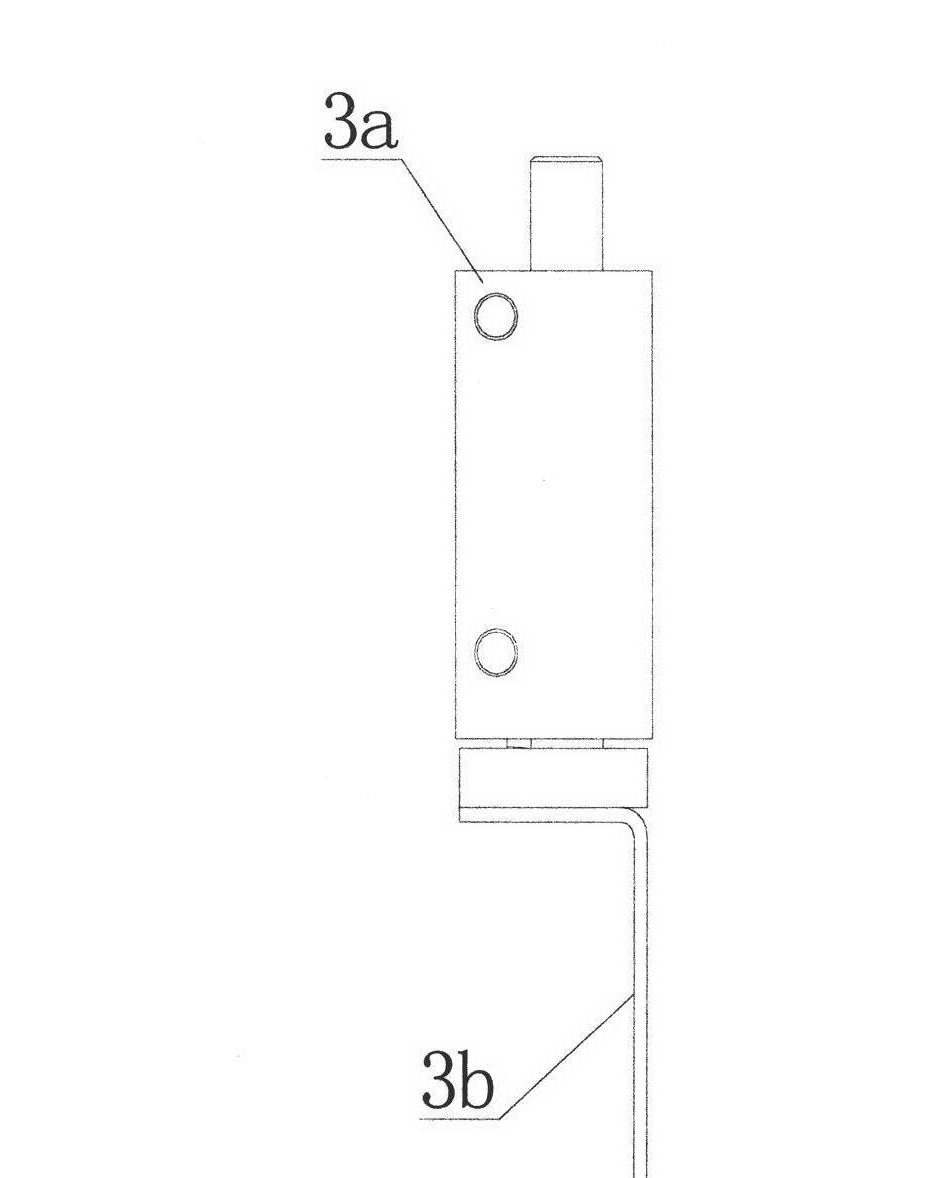

[0023] refer to Figure 1 to Figure 8 As shown, a kind of full-automatic rod cigarette conveying buffer device of the present invention comprises frame 1, is provided with conveyer belt 2 on frame 1, conveyer belt 2 is driven by driving motor, and conveyer belt 2 along the front and rear two sides of advancing direction An entrance blocking device 3 and an exit blocking device 4 are respectively arranged on the side, and a smoke pushing device 5 is arranged above the conveyer belt 2 between the entrance blocking device 3 and the exit blocking device 4. The direction of movement is vertical; the frame 1 on the side of the conveyor belt 2 is provided with a lifting smoke receiving platform 6, and the smoke pushing device 5 moves between the conveyor belt 2 and the lifting smoke receiving platform 6; The smoke device 5 circuit is connected with a controller, and the controller is also respectively connected with the drive motor of the conveyor belt 2, the entrance blocking device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com