Two-step etching method for resonant accelerometer resonant beam and support beam

An accelerometer and two-step corrosion technology, applied in the direction of measuring acceleration, velocity/acceleration/impact measurement, manufacturing microstructure devices, etc., can solve the problems of easy cracking and difficult bonding surface, etc., to reduce cross-axis interference and Effect of measurement error, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

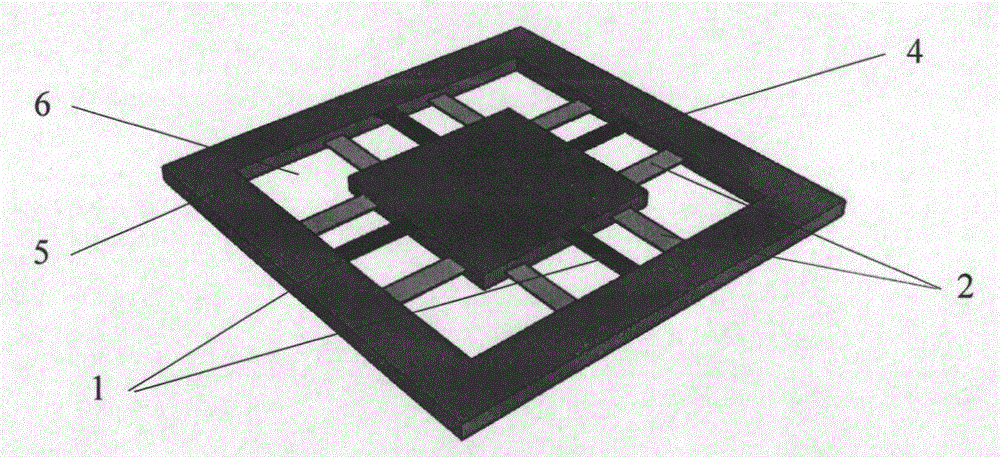

[0034] Embodiment 1: The thickness of the resonant beam (1) is 10 microns, the thickness of the support beam (2) is 50 microns, the thickness of the original silicon wafer (3) is 380 microns, and the width of the etching groove (6) is 661 microns. The production process determined based on this data is as follows:

[0035] 1) Thermal oxidation, making a silicon dioxide film with a thickness of 1.5 microns on both sides of the silicon wafer (3). (see attached image 3 [1])

[0036] 2) Photolithography on the back side to form a back etching window, the position of the window is facing the four corners of the resonant beam (1) and the etching groove (6). The length (along the length direction of the resonant beam (1)) and width (along the width direction of the resonant beam (1)) of the resonant beam back corrosion window (8) are 661 microns and 724 microns respectively compared with the length and width of the resonant beam (1). The back corrosion window (9) at the corner of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com