Comprehensive waste biomass resource transformation and utilization system and method through pyrolysis and gasification

A technology of pyrolysis and gasification of waste resources, applied in biofuels, gas purification of condensed non-gaseous materials, waste treatment, etc., can solve problems such as waste, water source and soil pollution, and ineffective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further explain the technical means and functions adopted by the present invention to achieve the intended invention purpose, the technical solutions proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

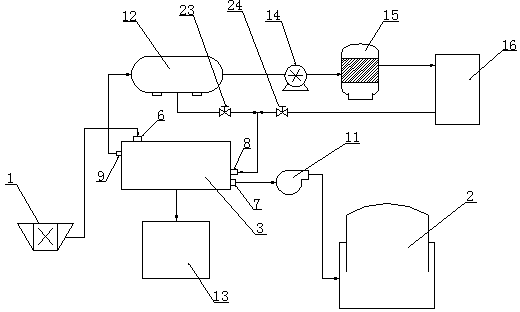

[0039] Such as figure 1 As shown, the biomass waste resource pyrolysis gasification comprehensive conversion utilization system includes a pyrolysis device 1 and a gas supply device 2 . The pyrolysis equipment 1 can adopt various common structural forms currently used in the field of pyrolysis and gasification of biomass resources such as straw. Biomass resources are pyrolyzed in the pyrolysis equipment 1 to produce high-temperature CO, CH 4 、H 2 and other flammable gases accompanied by high temperature CO 2 , N 2 Non-combustible gases and condensable gases such as high-temperature tar gas, acetic acid gas, and water vapor. The gas supply device 2 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com