Subdivision water injection, ball-off and profile control integrated tubular column for water injection well of oilfield and process of tubular column

A ball-throwing profile control and oilfield water injection technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve problems such as single function, uneven water absorption between layers, and thinner water injection strings that cannot be separated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

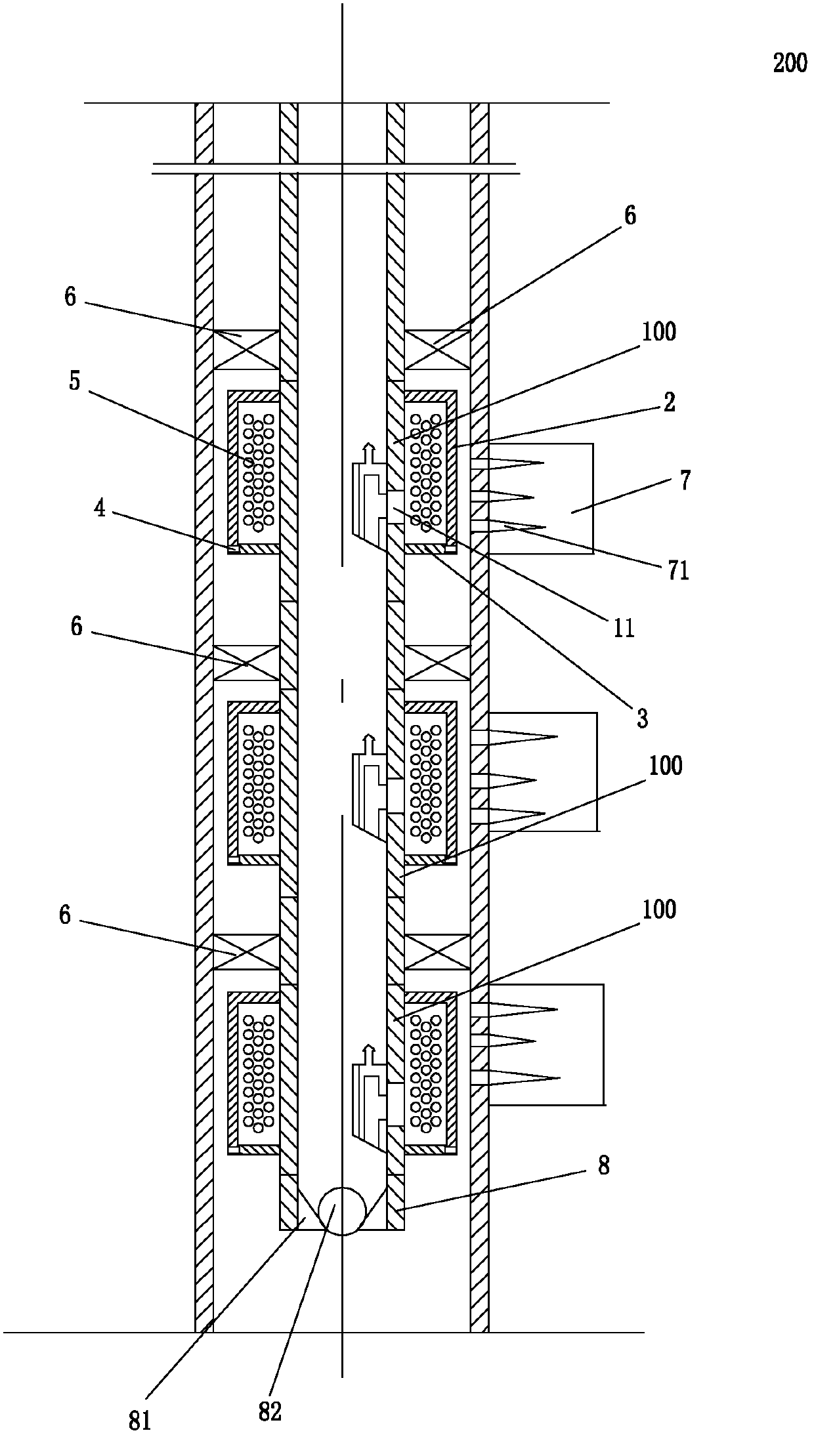

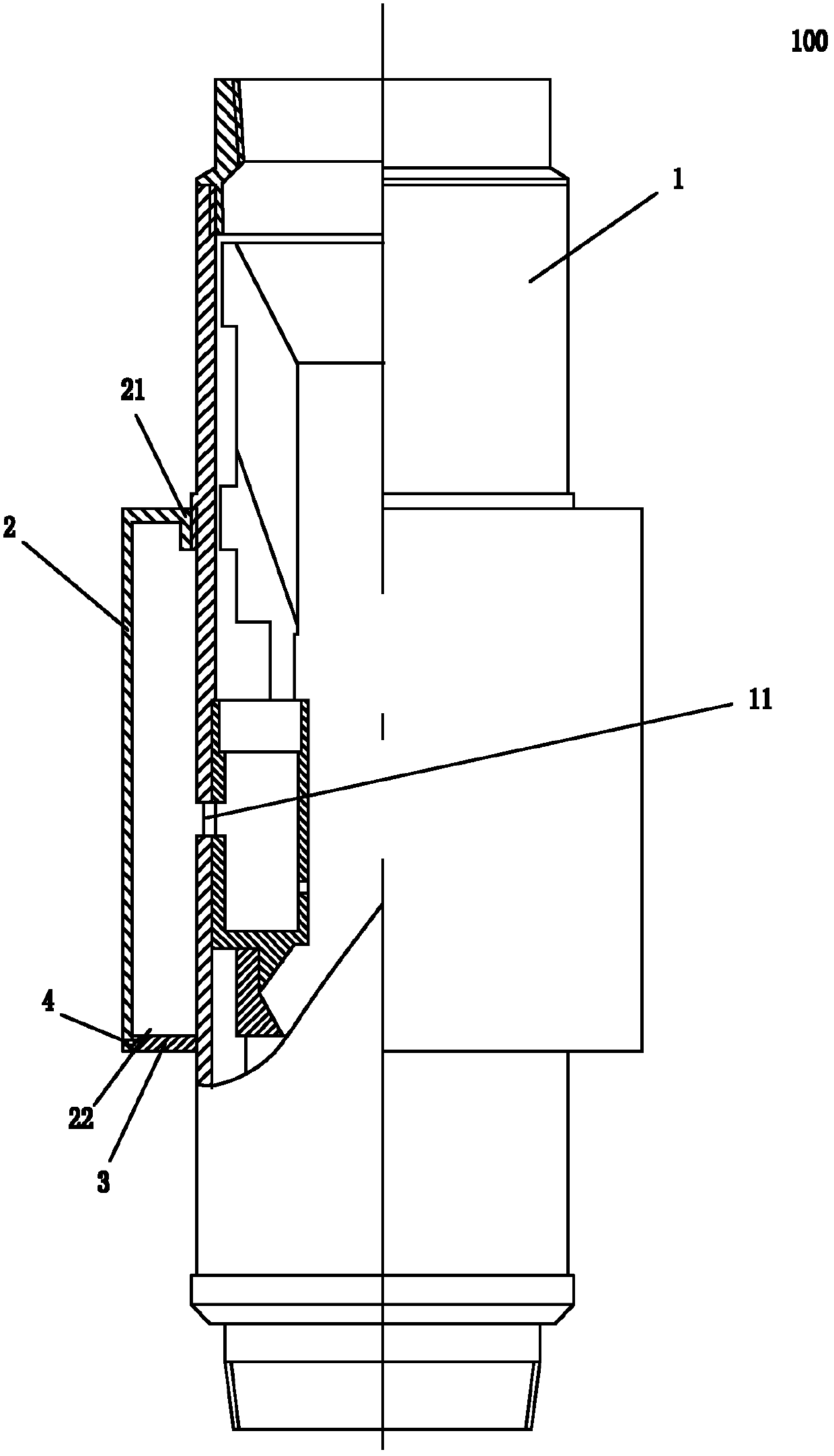

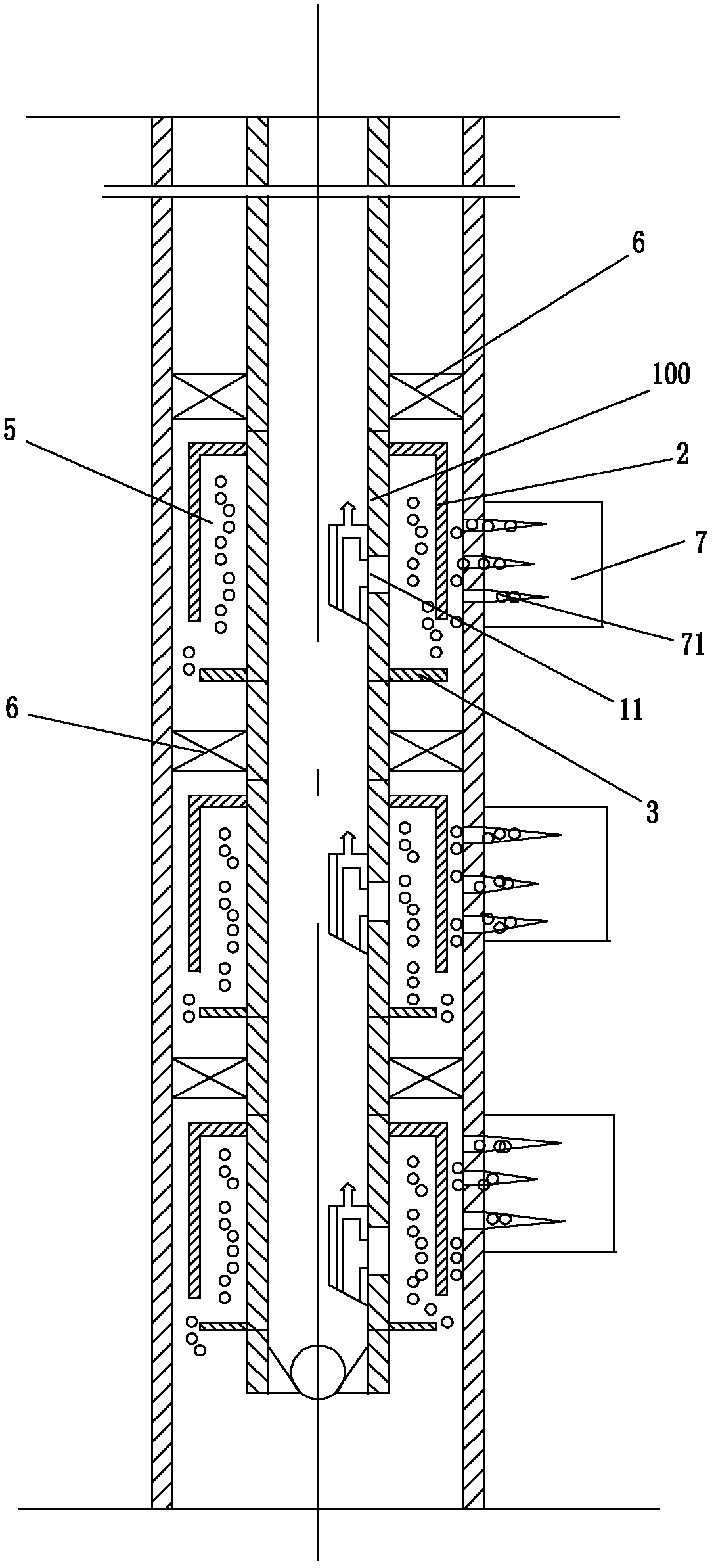

[0026] Such as figure 1 As shown, the present invention proposes an integrated pipe string 200 for subdivided water injection and ball injection profile control in oilfield water injection wells. , there is a packer 6 between the special water distributors 100 for injection and ball profile control of each injection well, and the distance between every two packers 6 is the same as the height of the corresponding subdivided interval. The bottom end of oil pipe is provided with ball valve 8, and described ball valve 8 is made of valve seat 81 and spherical valve core 82; figure 2 As shown, the special water distributor 100 for profile control of the injection well injection and pitching includes a water distributor 1, and the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com