Novel anti-twist split combination type sling tool

A sling and combined technology, applied in the field of slings, can solve the problems of wasting resources, cannot be separated separately, and have a short service life, and achieve the effects of high safety performance, prolonging service life and reducing use cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

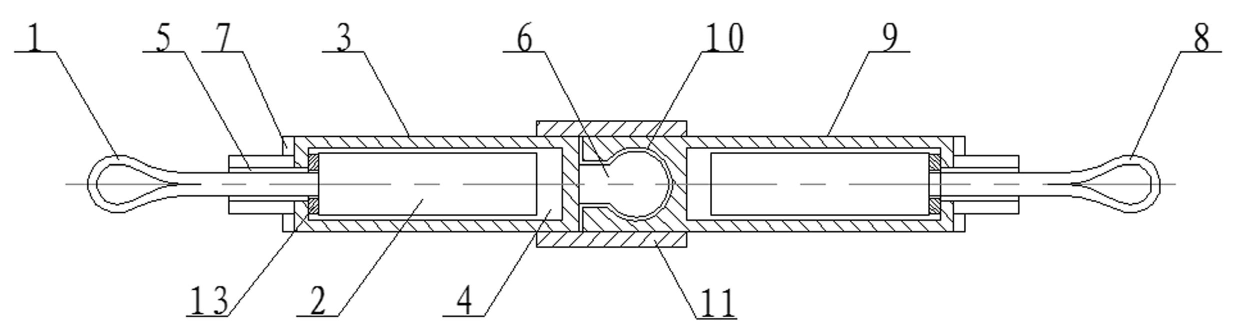

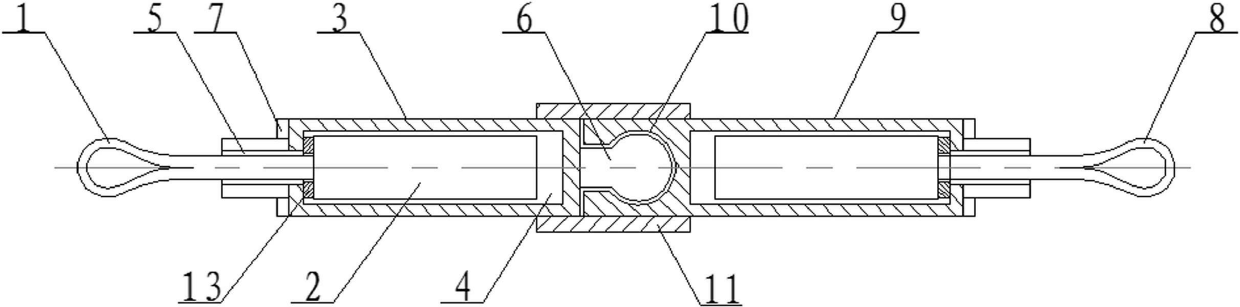

[0020] figure 1 As shown, a novel anti-twist split combined sling includes an upper noose 1, a noose male joint 3, a lower noose 8, a noose female joint 9 and a safety connection ring 11. One end of the upper noose 1 is a suspension ring structure, and the other end is crimped with an aluminum joint 2. The lower noose 8 has the same structure as the upper noose 1; One end of the rope sleeve male joint 3 is connected through the open rope chamber 5, and the pressed aluminum joint 2 is placed in the joint chamber 4, and an early warning pressure block 13 is arranged on the axial contact end surface of the pressure aluminum joint 2 and the joint chamber 4, and the rope sleeve male joint The rope part of 3 is placed in the rope chamber 5, and the snap ring 7 clamps the rope part in the rope chamber 5, or clamps the aluminum joint 2 in the joint chamber 4, and the other end of the rope sleeve male joint 3 is provided with a neck The spherical tenon 6, the spherical tenon 6, the jo...

Embodiment 2

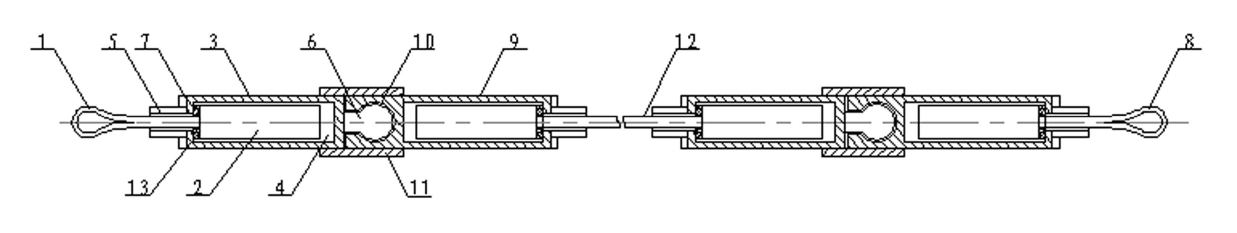

[0022] figure 2 As shown, a new anti-twist split combined sling includes an upper noose 1, a noose male joint 3, a lower noose 8, a noose female joint 9, a safety connection ring 11 and more than one section of transition rope 12 . The two ends of the transfer rope 12 are connected to the male connector 3 or the female connector 9 of the sheath through the aluminum joint 2. The non-sling end of the noose 8 is connected to the male or female joint of the noose through a snap ring by a pressed aluminum joint, and the male or female joint of the noose of the upper noose 1 is tenon-jointed with the female noose joint at one end of the transition rope 12 Or the sheath male joint, the sheath male joint or the sheath female joint at the other end of the adapter rope 12 is mortised and connected to the sheath female joint or the sheath male joint of the lower sheath 8, the upper sheath 1, the adapter rope 12, the lower sheath The rope sleeve 8 is connected to the rope sleeve male j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com