Gear selecting mechanism of transmission

The technology of a transmission and a shifting shaft is applied in the field of the shifting box mechanism of a micro-car transmission, which can solve the problems of large occupied space, complex structure and high cost, and achieve the effect of reducing the number of parts and simplifying the internal structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the present invention will be further described:

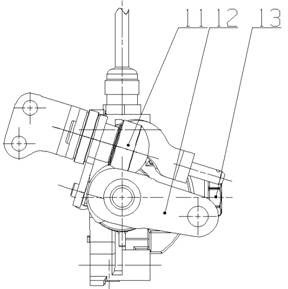

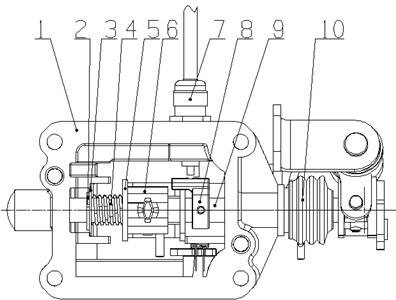

[0013] see figure 1 , figure 2 A transmission shift box mechanism with a single return spring is shown, including a gear selection mechanism, a gear shift mechanism, and a five-reverse gear interlocking mechanism.

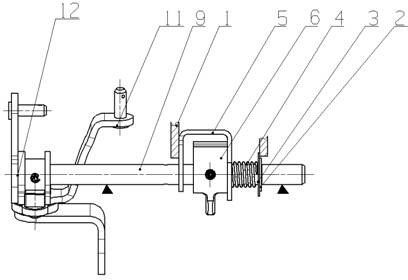

[0014] see image 3 , the improvement point of the present invention lies in the gear selection mechanism, which includes a gear shift box 1, a gear shift shaft 9, a shift lever 6, a shift support block 5, a return spring 4, a gear shift shaft washer 3 and a collar 2, etc. . The gear selection rocker arm 11 is fixed on the outside of the gear shift case 1 casing by screws and cooperates with the gear shift rocker arm. The shift shaft 9 is connected in series in the shift case 1, and is supported by the two ends of the shift case. The shift rocker arm 12 and the shift lever 6 are connected on the shift shaft 9 by pins, and the collar 2 is stuck in the groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com