Ball valve base structure with anti-block pre-tensioning device

An anti-jamming and valve seat technology, which is applied to cocks, valve devices, engine components, etc. including cut-off devices, can solve the problems of low material utilization and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

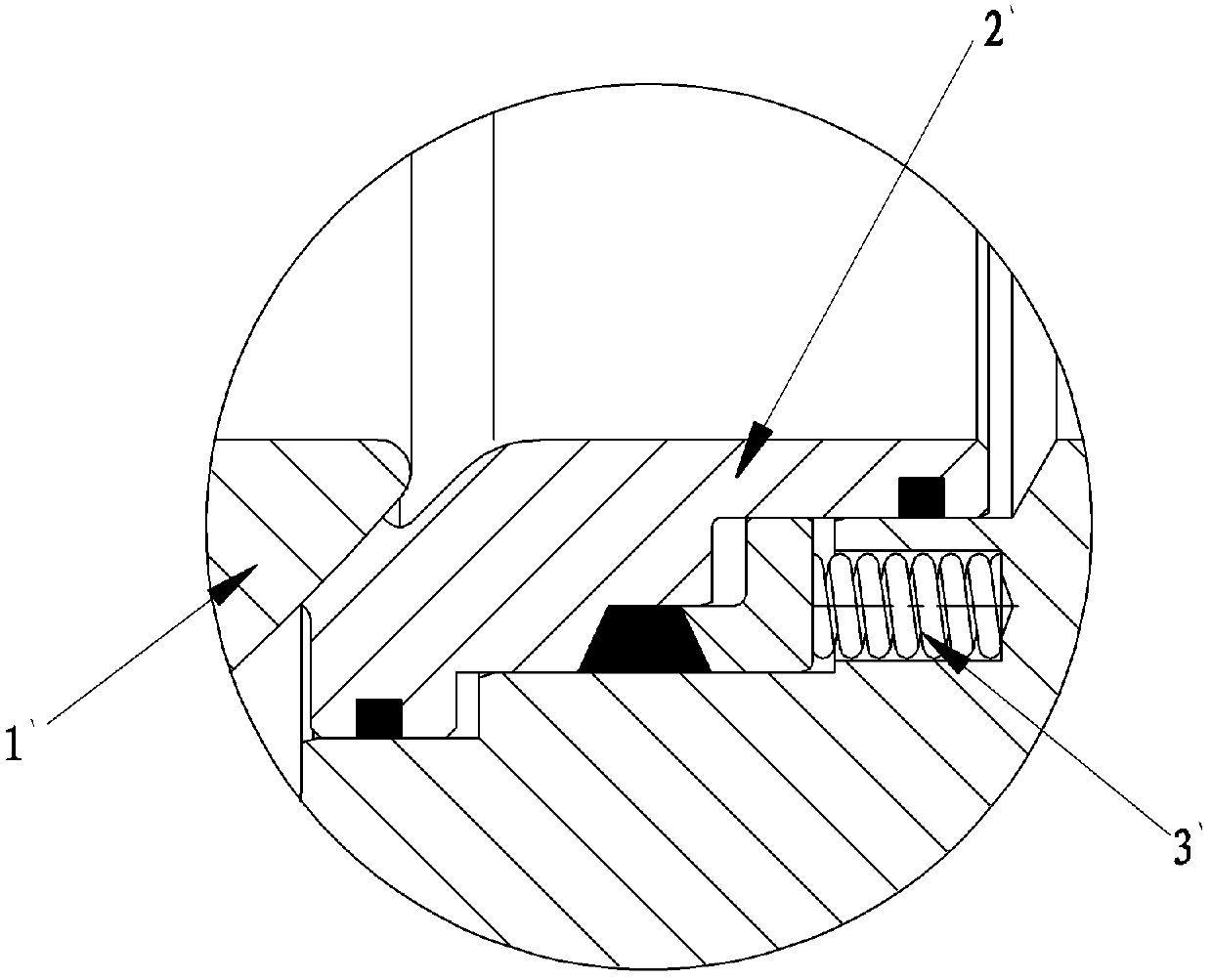

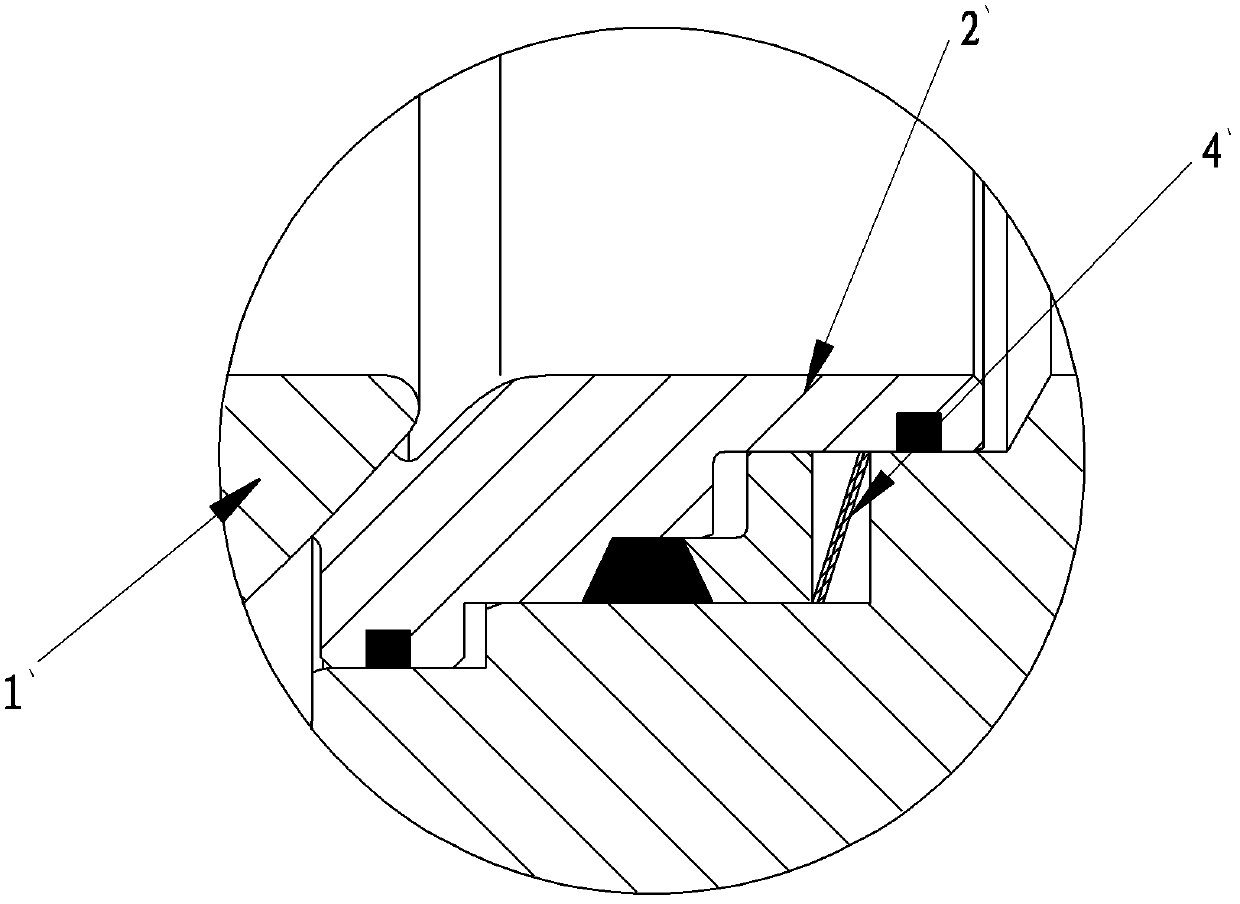

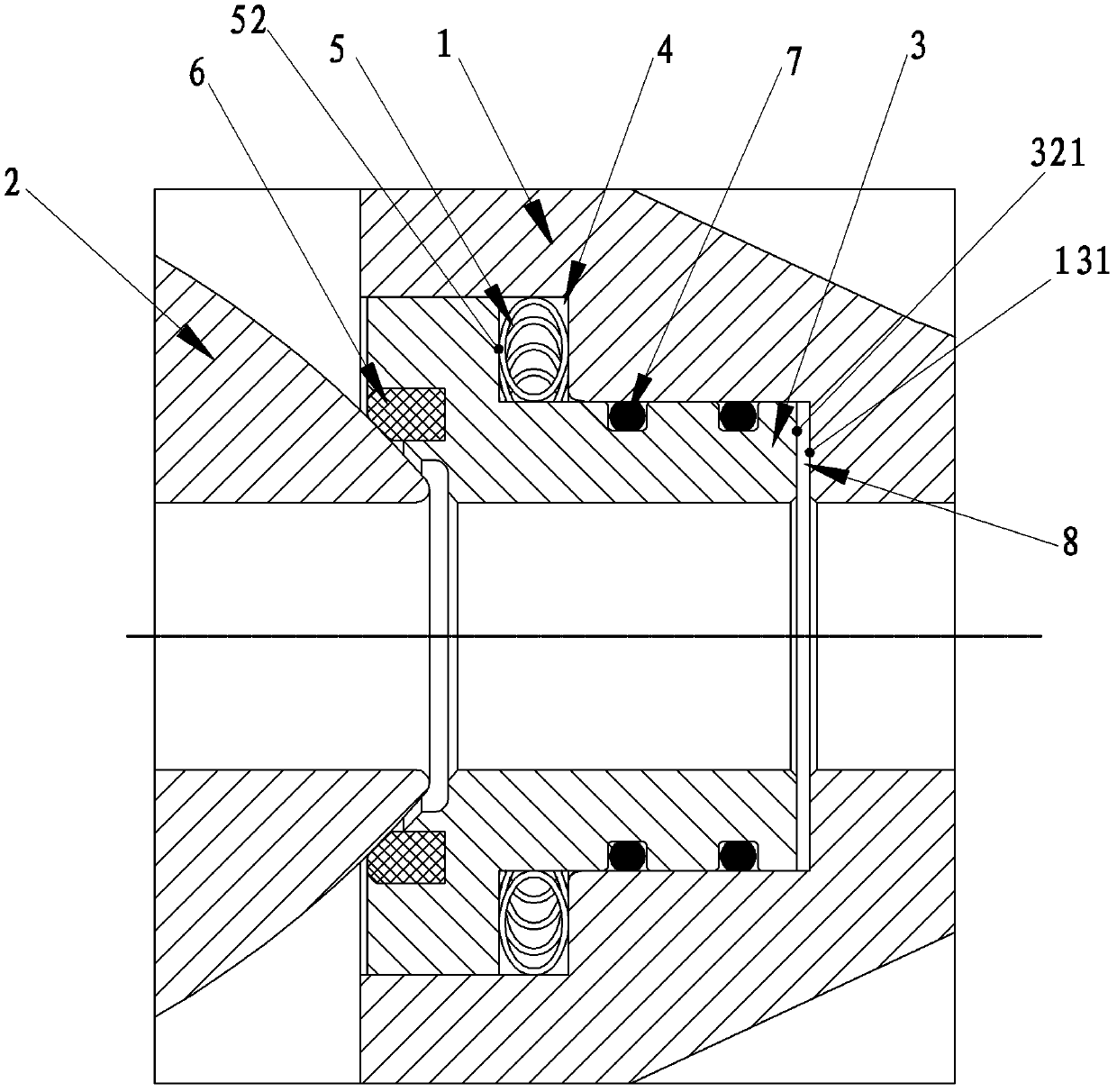

[0020] Such as image 3 — Figure 5 The seat structure of a ball valve with an anti-seize pre-tightening device shown includes a valve body 1, a ball 2 disposed in the valve cavity of the valve body 1, and a valve seat 3 that is in sealing fit with the ball 2. The valve body 1 There is an annular buffer chamber 4 between the valve seat 3. It should be noted that the buffer chamber 4 is formed after the valve body 1 and the valve seat 3 are installed and combined; the annular buffer chamber 4 is provided with an anti-seize device The anti-seize device includes a helical elastic ring 5 formed by a steel wire around the annular buffer chamber 4, and a number of contact points on both sides of the helical elastic ring 5 are in elastic contact with the valve seat 3 and the valve body 1 respectively. Cooperate. In the above scheme, a buffer chamber 4 is provided between the valve body 1 and the valve seat 3, and a spiral elastic ring 5 wound by a steel wire is arranged in the buff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com