Steel-plastic composite pressure pipe

A steel-plastic composite and pressure pipe technology, applied to pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve problems such as easy scaling, user and company losses, easy deformation, etc., to achieve convenient repair and maintenance, avoid Excavation damage, not easy to corrode and aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

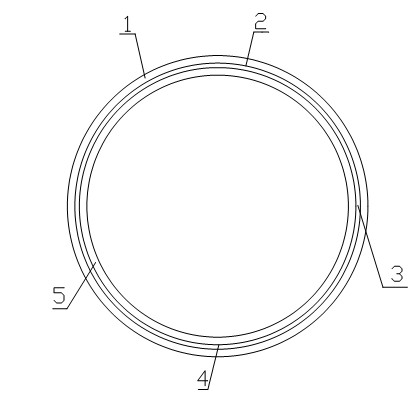

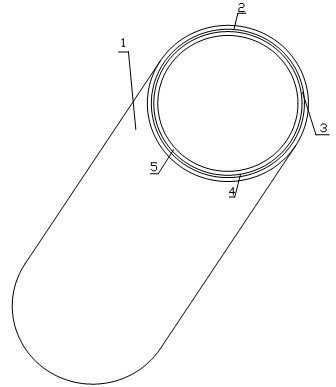

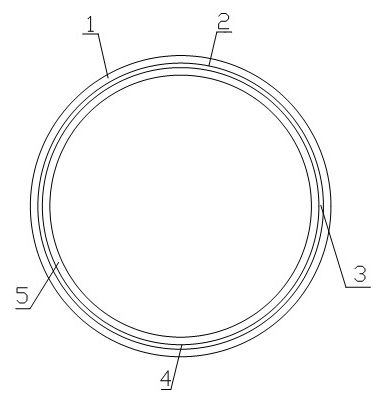

[0010] Such as figure 1 , 2 As shown, a steel-plastic composite pressure pipe includes an outer plastic layer 1, a steel pipe layer 3, and an inner plastic layer 5. The outer plastic layer 1 and the steel pipe layer 3 are bonded and connected by the outer rubber layer 2, and the steel pipe layer 3 and the The inner plastic layer 5 is bonded and connected by the inner rubber layer 4 to form a composite body. The cross section of the steel-plastic composite pressure pipe is circular. The inner plastic layer 5 and the outer plastic layer 1 of the present invention are made of non-polar material polyethylene It has stable chemical properties, is not easy to corrode and age in various acid and alkali environments, and prolongs the service life. The steel-plastic composite pressure pipe can be tracked by a magnetic metal detector, and there is no need to bury additional tracking protection marks to avoid excavation damage. , which provides great convenience for emergency repair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com