Intermittent control method for eliminating static deviation of main steam pressure of fossil fuel fired power unit

A main steam pressure, static deviation technology, applied in the combustion method, combustion control, fuel supply and other directions, can solve the problems of difficult steam pressure static deviation, poor ability to eliminate steam pressure static difference, unstable control system, etc. Achieve the effect of eliminating static deviation and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described below with reference to the accompanying drawings.

[0035]A kind of intermittent control method of the present invention to quickly eliminate the static deviation of the main steam pressure of the thermal power unit is realized by the following technical scheme:

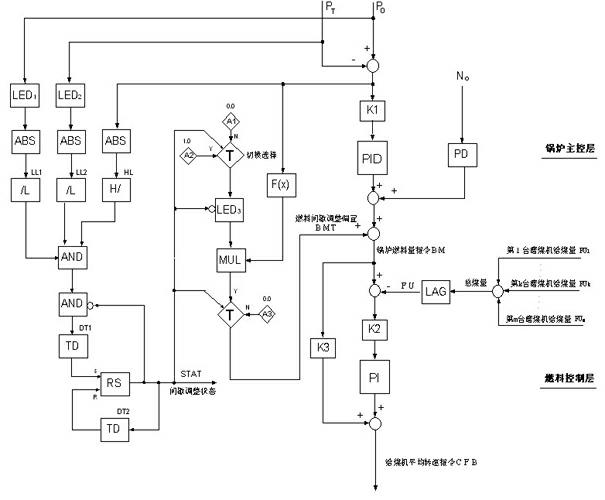

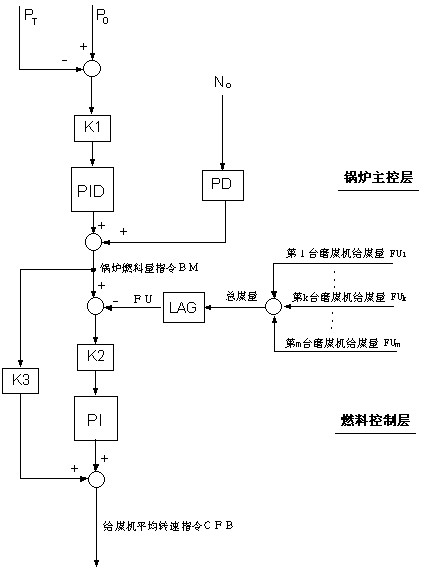

[0036] Real-time monitoring of the static deviation of the main steam pressure of the thermal power unit, when the static deviation of the steam pressure exceeds the specified value, using the step output characteristics of the differential control module, on the basis of the original boiler fuel quantity command, through intermittent rapid superposition and steam pressure static The fuel volume command offset corresponding to the deviation can adjust the fuel volume of the boiler in time, so that the static deviation of the main steam pressure of the unit can be quickly eliminated.

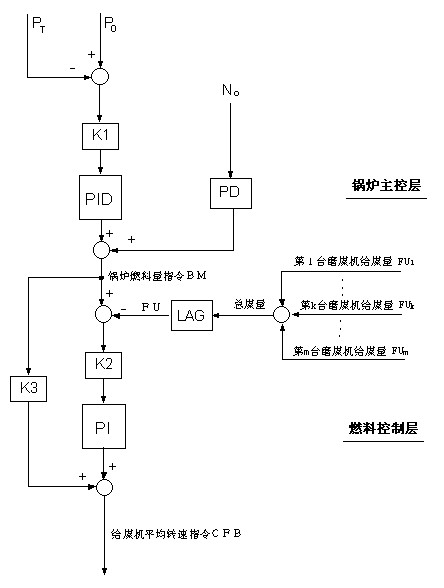

[0037] The fuel adjustment of the boiler is divided into upper and lower layers, namel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com