Movable online detection device and detection method of enamelled wire diameter

A detection device and enameled wire technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as rising labor costs, unfavorable improvement of product quality, and damage to enameled wires, so as to avoid the risk of return or customer complaints afterwards, Guarantee the quality of the finished product line and process capability, and improve the measured density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

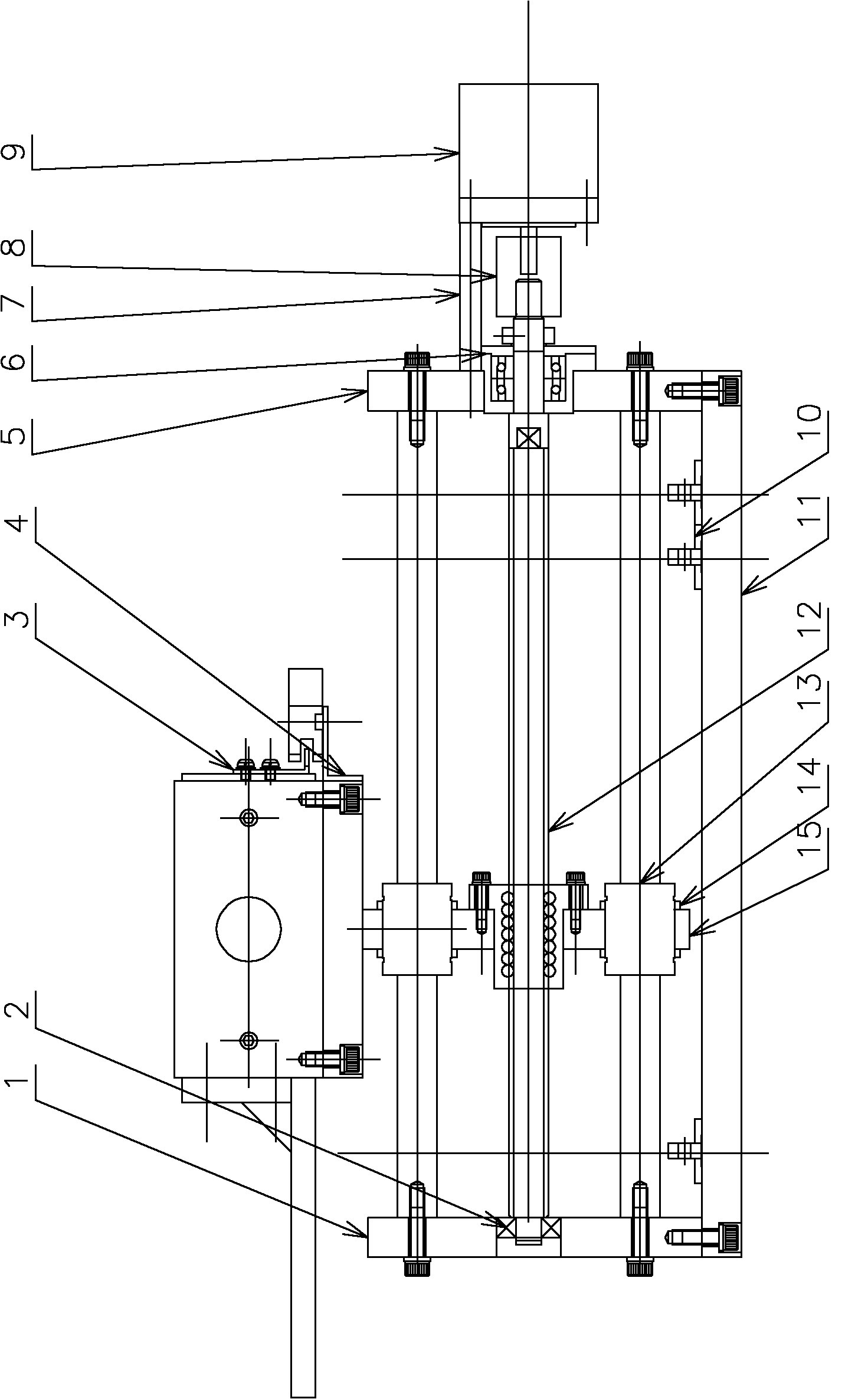

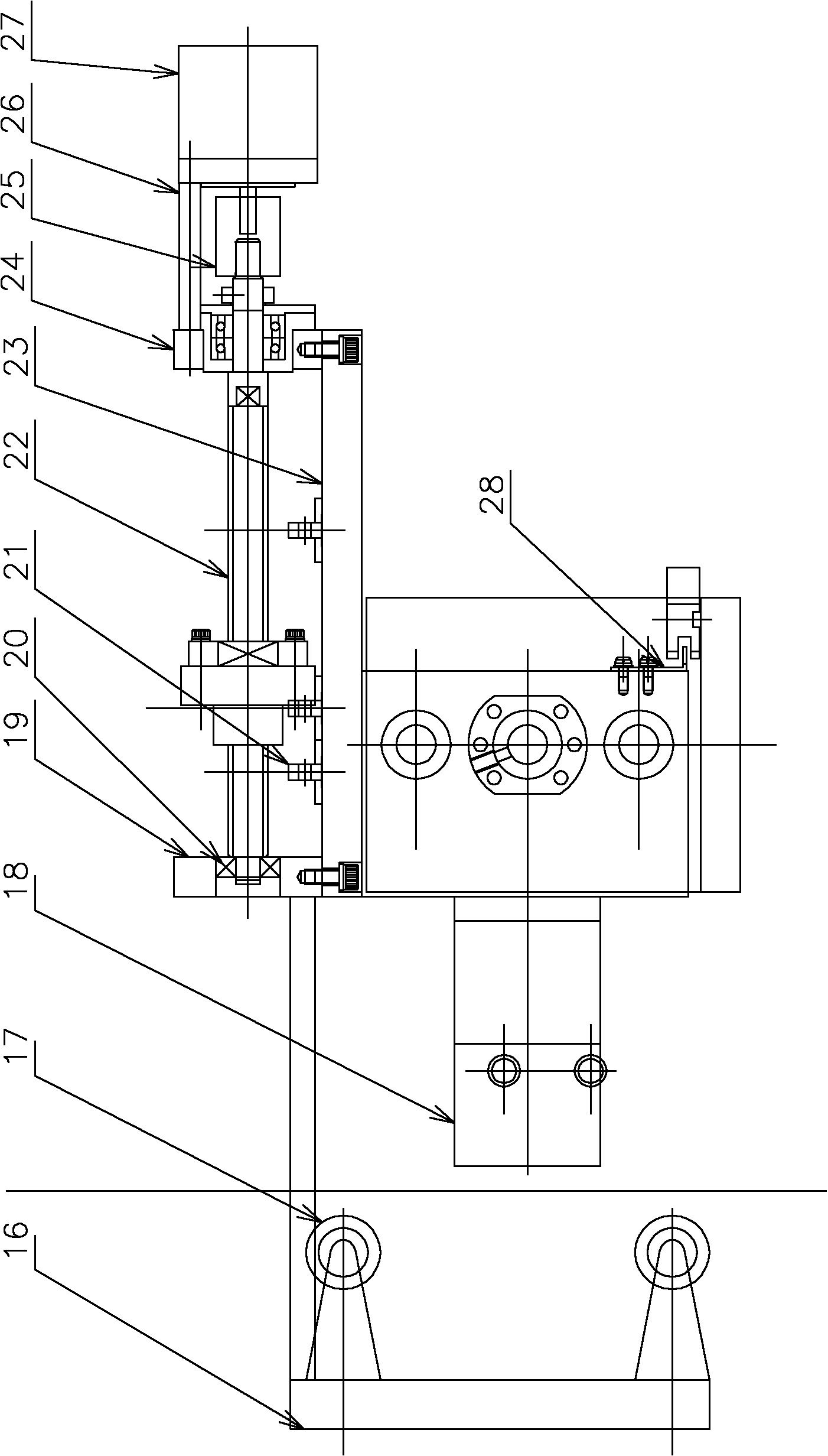

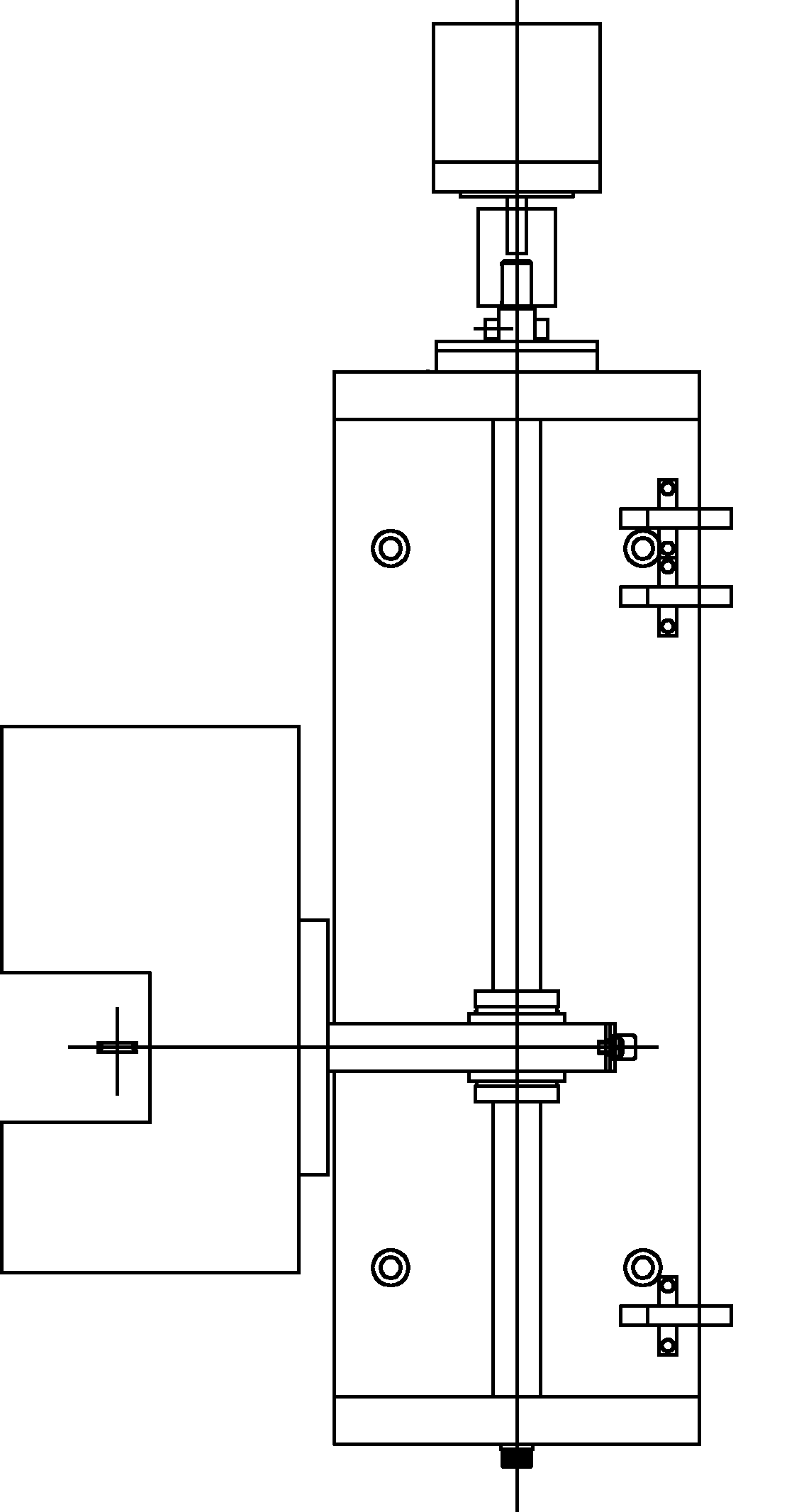

[0050] The invention discloses a mobile online detection device for enameled wire diameter, wherein, such as figure 1 , 2 , 3, 4, comprising: laser caliper 18, enameled wire pressing device, the horizontal mechanism that can drive described laser caliper 18 and enameled wire pressing device to move laterally, can drive described enameled wire pressing device to carry out longitudinal A moving longitudinal mechanism, a driving device and a controller; the enameled wire pressing device is connected with the transverse mechanism and the longitudinal mechanism respectively, and the laser caliper 18 is fixed on the transverse mechanism; the controller controls the actions of the transverse mechanism and the longitudinal mechanism, and Control the detection action of the laser caliper; the laser caliper sends the detected data information to the controller to judge whether it is qualified or not.

[0051] The enameled wire pressing device includes a pull rod 16 and a crimping roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com