Pipeline flow-velocity imaging and flow measuring method based on ultrasonic

A flow measurement, ultrasonic technology, applied in the direction of fluid velocity measurement, measurement of flow/mass flow, liquid/fluid solid measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described below in conjunction with the accompanying drawings.

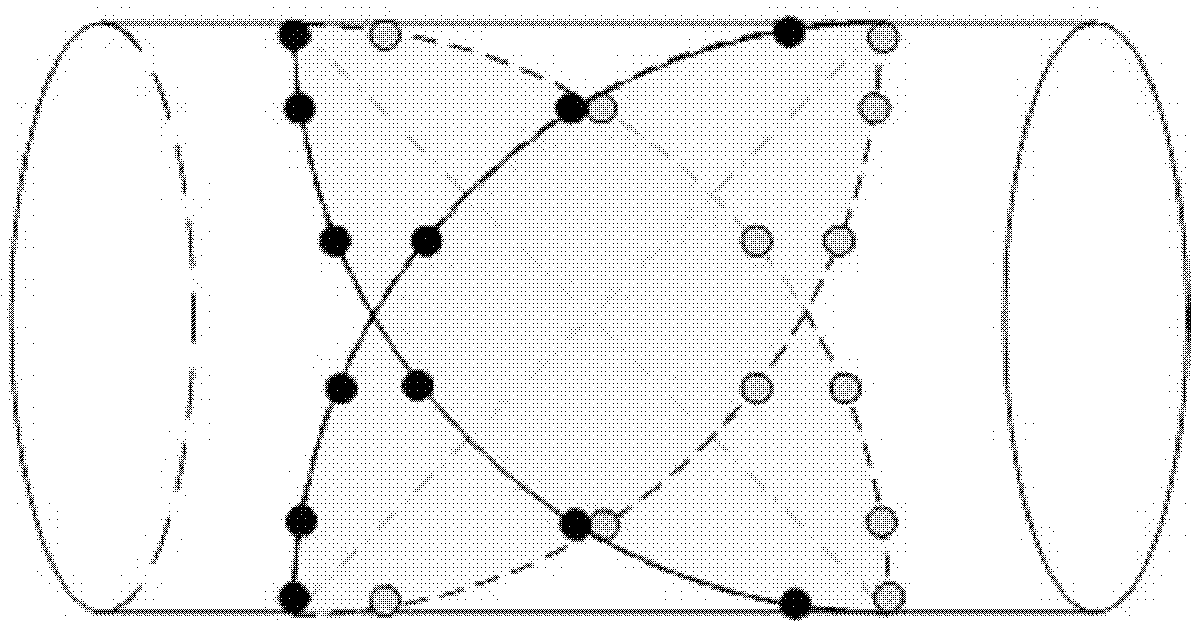

[0029] A pipeline flow velocity imaging and flow measurement method based on ultrasound, comprising the following steps:

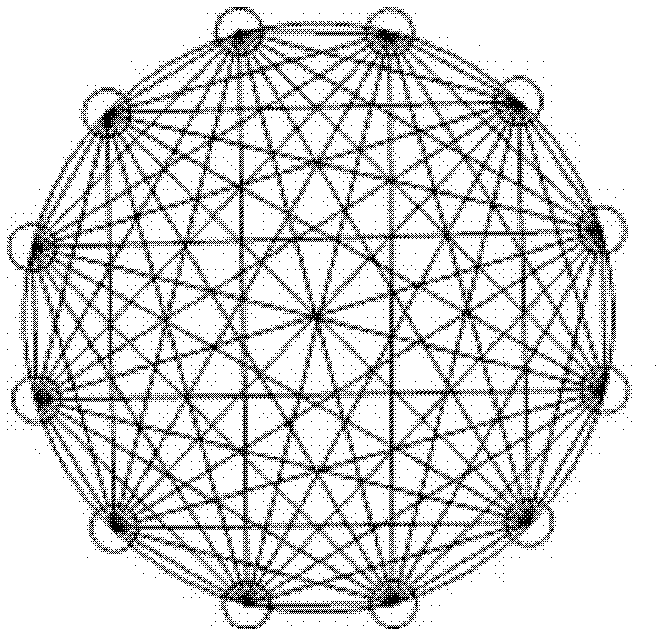

[0030]Step 1: Manufacture an ultrasonic probe composed of three piezoelectric units for transmitting and receiving ultrasonic signals. Each piezoelectric unit can complete the task of transmitting and receiving ultrasonic waves. Each piezoelectric unit has a certain sound beam angle , the sound beam angle satisfies the condition that the sound beam angle of the boundary piezoelectric unit involves the four adjacent probes respectively, and the sound beam angle of the central unit involves the three probes directly opposite;

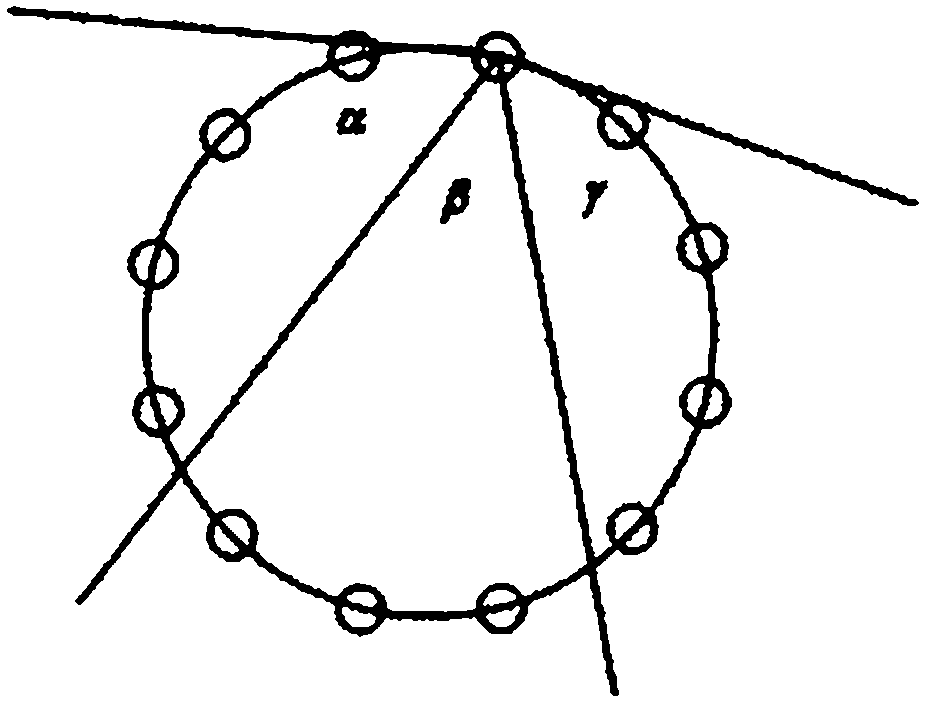

[0031] Figure 2b is the placement form of the three piezoelectric units in the ultrasonic probe, α, β, and γ are the sound beam angles of each unit, Figure 2a Other ultrasonic probes within the beam angle coverage of each piezoele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com