Thermocouple temperature sensor with fast response speed

A temperature sensor and response speed technology, which is applied to thermometers, thermometers, instruments, etc. that use electric/magnetic elements that are directly sensitive to heat, can solve problems such as missed detection and lower detection accuracy, and achieve improved detection accuracy and fast response speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

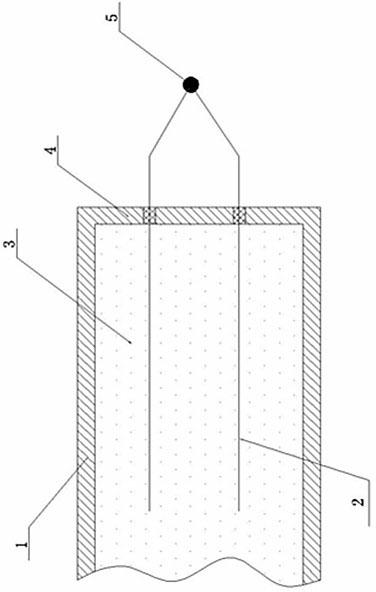

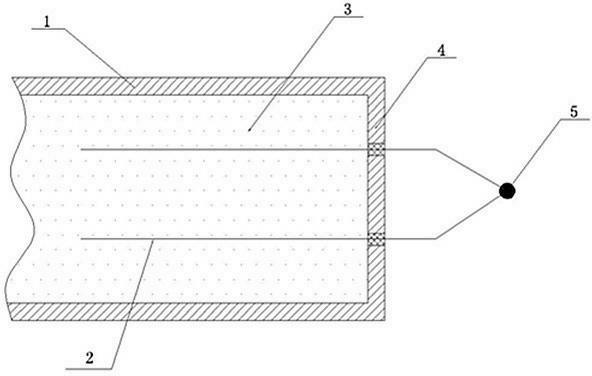

[0007] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 Shown: the same as the prior art, there is a protective sleeve 1, there are electrodes 2 and insulating filling materials 3 arranged in parallel in the protective sleeve 1, and the front end of the protective sleeve 1 has an encapsulation layer 4, which is different from the prior art The electrode 2 passes through the encapsulation layer 4 , and the joint point 5 (hot end) of the electrode 2 is located outside the encapsulation layer 4 , that is, the joint point 5 is not in contact with the encapsulation layer 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com