In situ tension specimen for mechanical performance testing of TSV (Through Silicon Vias) copper interconnection material

A technology of in-situ stretching and material mechanics, applied in the direction of analyzing materials, measuring devices, scientific instruments, etc., can solve reliability problems, hinder the process of industrialization, and cannot obtain in-situ mechanical characteristic parameters of TSV copper materials, etc. , to achieve the effect of high yield, good reproducibility and direct mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

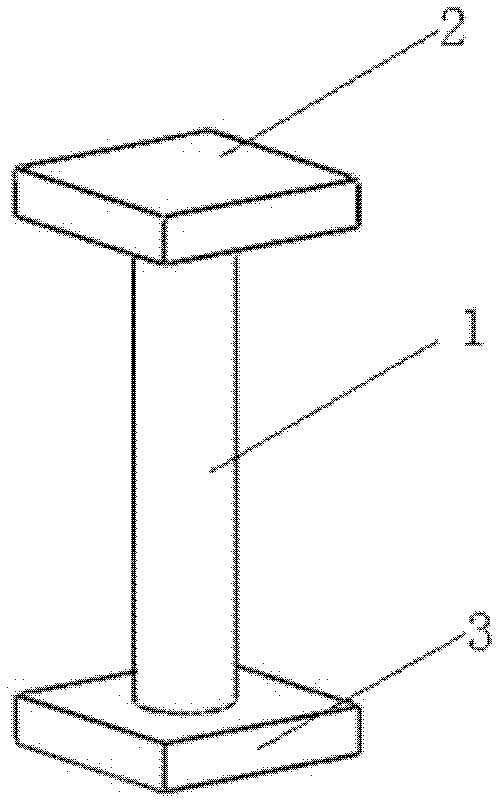

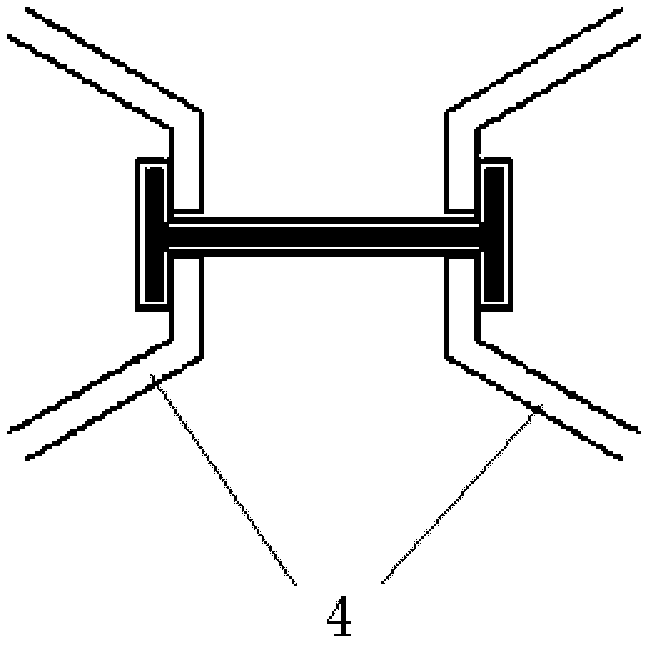

[0018] Such as figure 1 As shown, this embodiment provides an in-situ tensile sample structure of a TSV copper interconnection material, and the in-situ tensile sample includes a sample part and a clamping part for clamping the sample.

[0019] The sample part is the metal pillar 1 formed in the through-silicon via, and the material is copper.

[0020] The clamping part includes an upper clamping end 2 and a lower clamping end 3, the upper and lower clamping ends are square plate structures, and the material is copper or nickel.

[0021] The thickness of the sample part 1, the thickness of the upper clamping end 2, and the thickness of the lower clamping end 3 are all in micron order.

[0022] Specifically, in this embodiment, the sample part 1 is in the shape of a circular metal column with a diameter of 5-50 microns and a height of 10-150 microns;

[0023] In this embodiment, the sample part 1 is made of metallic copper.

[0024] In this embodiment, the upper clamping end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com