Device for generating electricity by collecting environmental low-grade energy source

A low-grade energy generation technology, applied in the direction of generators, generators/motors, and electrical components that convert kinetic energy into electrical energy, can solve problems such as low efficiency and high-grade pressure energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

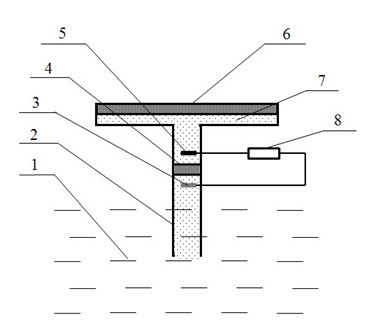

[0023] see figure 2 , a device for collecting low-grade energy from the environment to generate electricity, it includes a liquid inlet pipe 2 and a liquid storage chamber 7, the upward surface of the liquid storage chamber 7 is an evaporation film 6, and the liquid inlet pipe 2 and the liquid storage chamber 7 are connected by a nanochannel 4 ; There is an Ag electrode 3 in the liquid inlet pipe 2, and there is Ag in the liquid storage chamber 2 CO 3 or AgO electrode5, Ag electrode and Ag 2 CO 3 Or the AgO electrode is connected to the load or energy storage device 8 through wires.

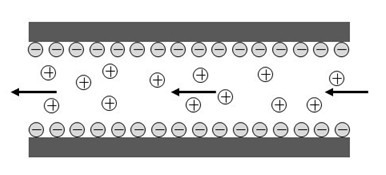

[0024] When working, the carbonic acid solution in the liquid storage chamber is continuously evaporated through the gas-liquid interface in the evaporation film, and the evaporation film is a nano- or micro-porous film. The capillary force generated by the evaporation film provides a continuous driving force for the evaporation of the carbonic acid solution. The electrical energy generated ...

Embodiment 2

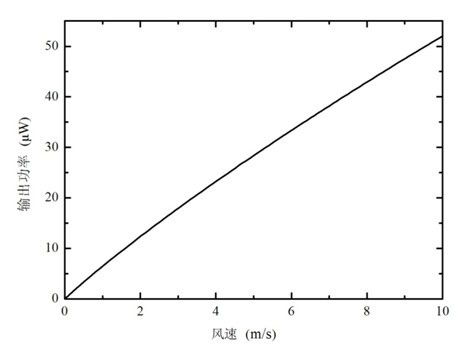

[0028] The use of wind energy. see figure 2 , the evaporation film is a nanoporous material with an area of 1 cm 2 , the concentration of the carbonic acid solution is 3×10 -4 mol / L, the nanochannel is composed of multiple parallel nanochannels with a length of 50μm, a width of 55nm, and a height of 4.5mm, and the number of channels is 5×10 4 . Under the environment of 25 degrees, different wind speeds of 0-10m / s are used to act on the evaporation film in parallel, and the structural features of other parts are the same as that of embodiment 1. Through calculation, it can be obtained that as the wind speed increases, the output power of the system increases. When the wind speed is 10m / s, the output power of the system is 52.1μW, see image 3 . The system has extremely high apparent wind energy utilization efficiency, the lower the wind speed, the higher the efficiency, which can reach more than 100%, see Figure 4 , indicating that the thermal energy in the environmen...

Embodiment 3

[0030] use of excess heat. see figure 2 , the evaporation membrane material is a nanoporous material with an area of 1 cm 2 , the concentration of the carbonic acid solution is 3×10 -4 mol / L. The nanochannel is composed of multiple parallel nanochannels with a length of 50 μm, a width of 55 nm, and a height of 4.5 mm. The number of channels is matched with the waste heat temperature to obtain the highest power generation. The different residual heats of 30 to 80 degrees act on the evaporation film, and the structural features of other parts are the same as in Embodiment 1. It can be obtained by calculation, see Figure 5 , as the waste heat temperature increases, the system output power increases. When the evaporation temperature is 80 degrees, the output power of the system is 55.4μW.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com