Multi-station scattered mold conveying device

A multi-station, mold technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of high cost, complex structure, difficult installation, etc., and achieve the effect of reversible movement, controllable operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with embodiment and accompanying drawing thereof, the present invention will be further described:

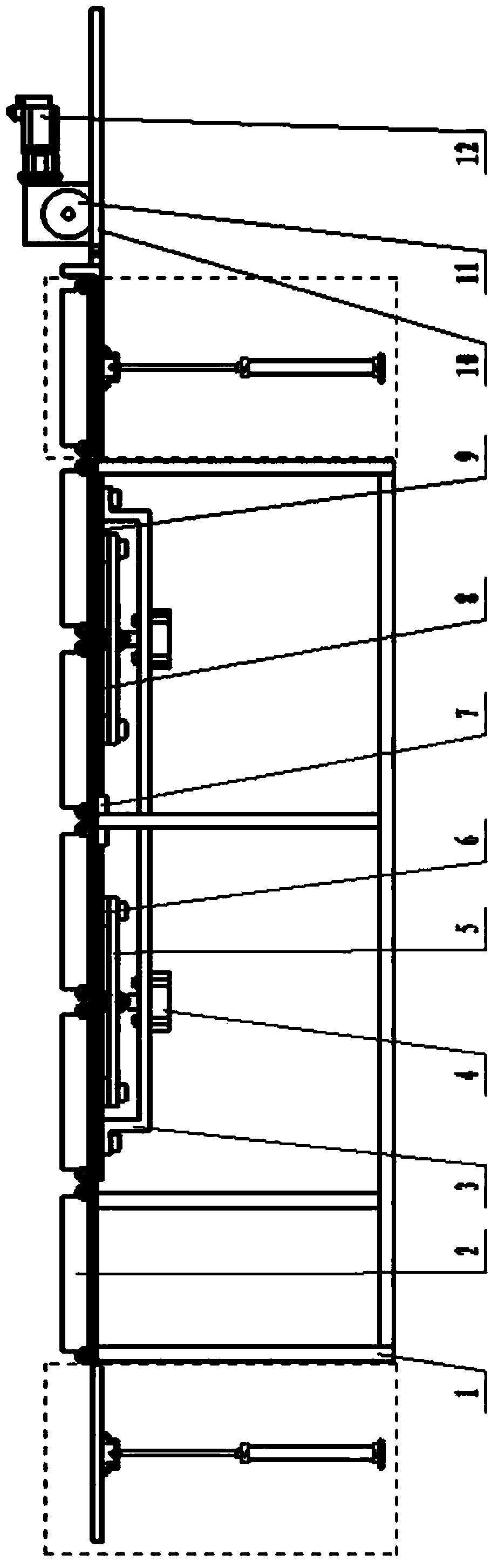

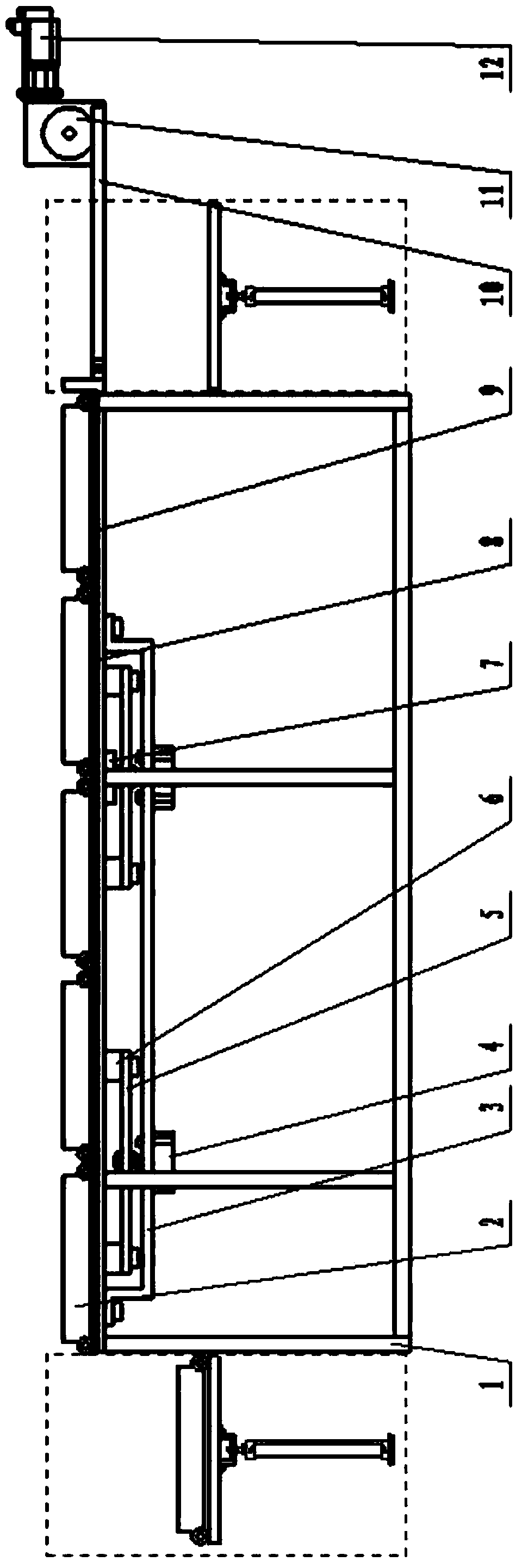

[0009] The multi-station scattered mold conveying device designed by the present invention (abbreviation device, see figure 1 , 2 ), mainly including bracket 1, mold 2, cylinder seat 3, cylinder 4, positioning frame 5, positioning pin 6, slide seat 7, guide rail 8, push plate 9, push rod 10, transmission mechanism 11 and motor 12; it is characterized in that The motor 12 is connected to the bracket 1 through screws, and the motor 12 converts the rotational power into linear power through the transmission mechanism 11 and transmits it to the push rod 10. The push rod 10 is connected with the push plate 9 through screws, and the sliding seat 7 is fixed on the bracket 1 , the guide rail 8 is also installed on the bracket 1, and the upper push rod 10 drives the push plate 9 to make a linear reciprocating motion in the slide seat 7; the two ends of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com