Dual-purpose type welding working device

A working device and dual-purpose technology, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problem of reducing the welding efficiency of U-shaped pipe 11 or straight pipe 12, increasing equipment costs, and increasing the number of U-shaped pipes 11 or straight pipes. 12 Placement time and other issues, to achieve the effect of saving placement time, saving working hours, and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following description will be given in conjunction with specific embodiments.

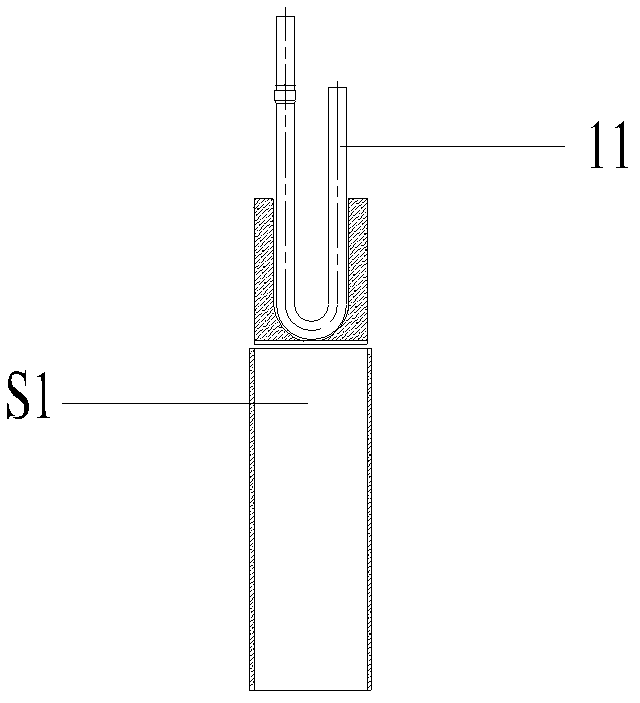

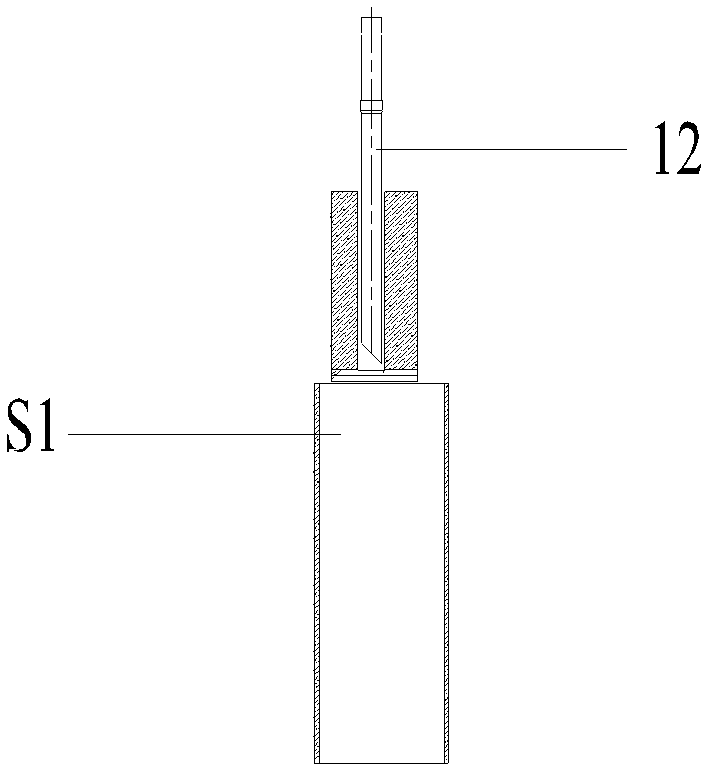

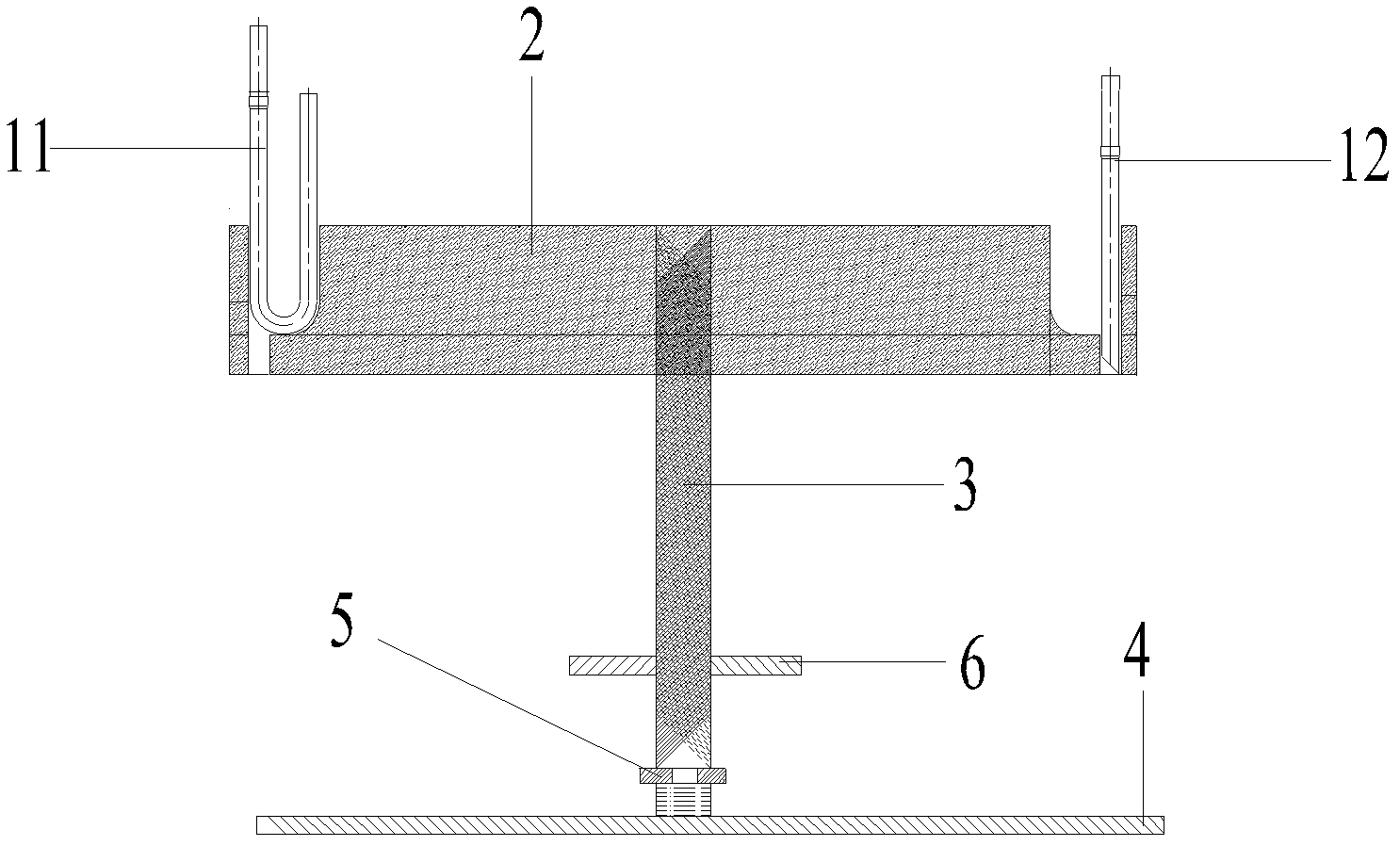

[0019] See image 3 with Figure 4 , image 3 It is a schematic diagram of the structure of a dual-purpose welding working device in an embodiment of the present invention; Figure 4 It is a schematic top view of a dual-purpose welding working device in an embodiment of the present invention.

[0020] The dual-use welding working device provided by the embodiment of the present invention includes a base 4 and a placing table 2. The placing table 2 is connected to the base 4 through a mounting post 3, and the placing table 2 is provided with a U-shaped tube placing hole 7 and The straight pipe placement hole 8 and the U-shaped pipe placement hole 7 have an oval structure, and the straight pipe placement hole 8 has a circular structure.

[0021] The straight pipe placement hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com