Continuous production equipment for polyurethane insulation board cement-based coils

A polyurethane thermal insulation board and production equipment technology, which is applied in the direction of layered products, lamination devices, lamination auxiliary operations, etc., can solve the problems of long coating time, large floor space, and low efficiency, and achieve improved production efficiency, The effect of high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

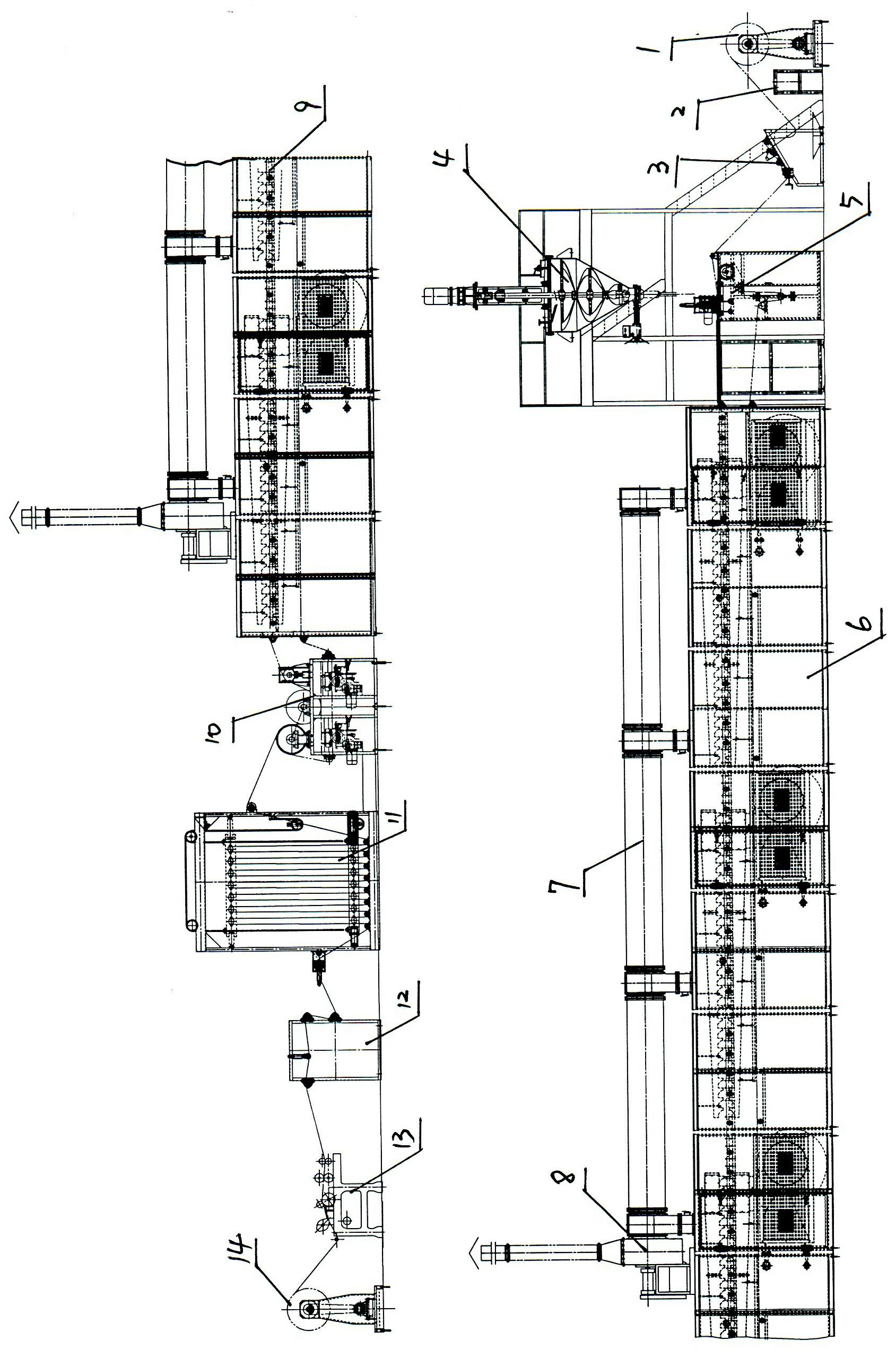

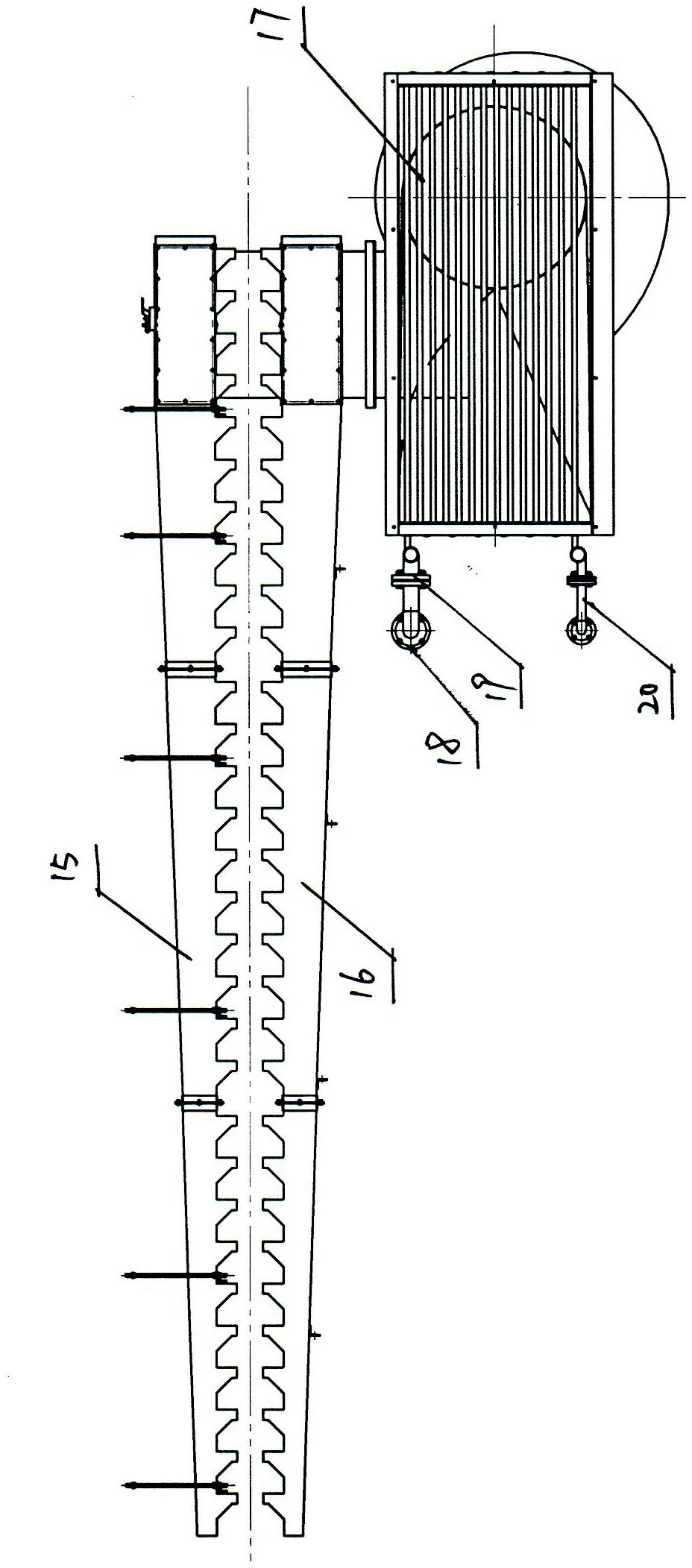

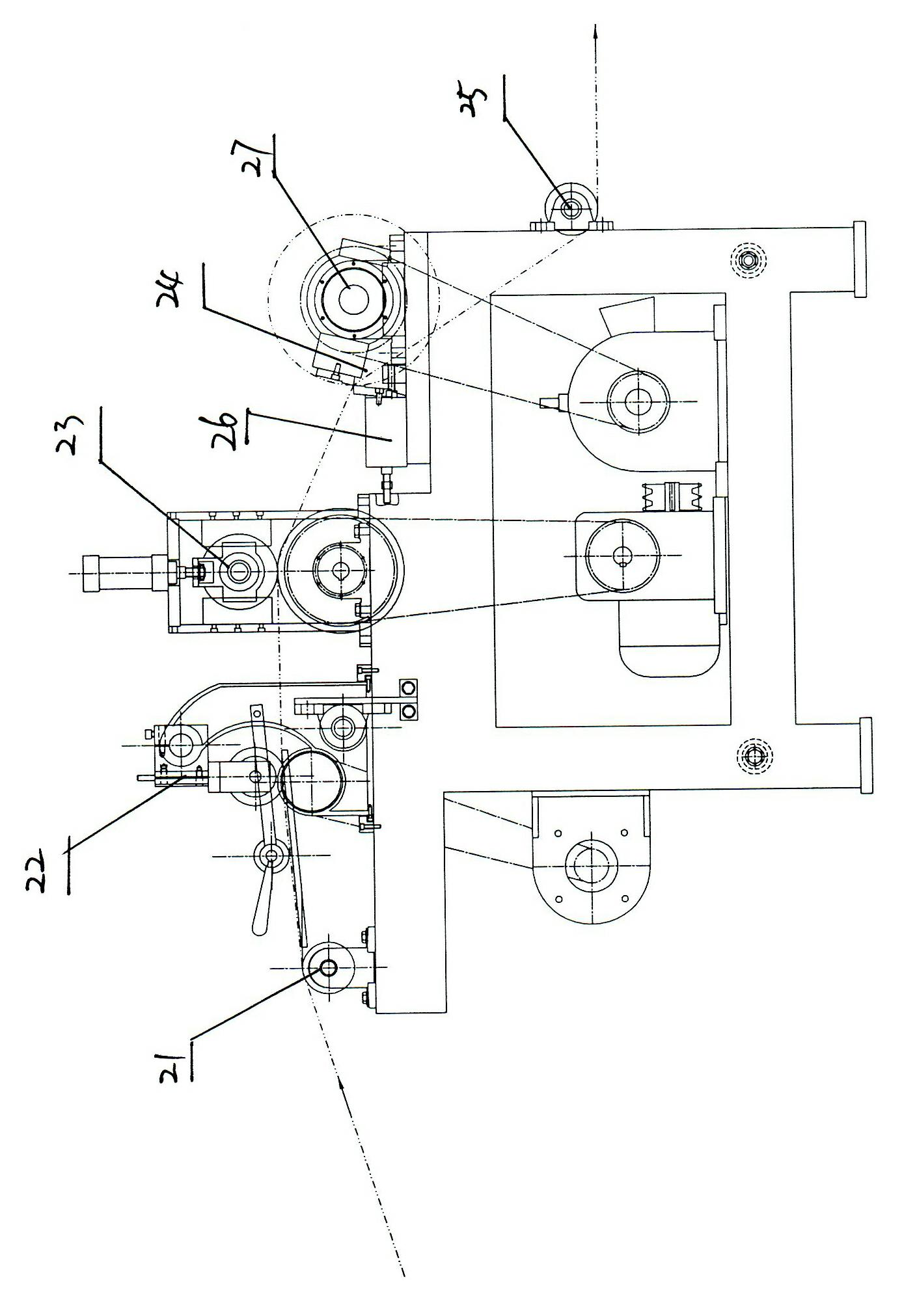

[0021] A continuous production equipment for cement-based coils of polyurethane insulation boards, including a mesh cloth conveying mechanism, a conveyor belt and conveyor belt conveying rollers 9, a drying mechanism 6, a conveyor belt and coil separation mechanism 10, a cloth storage mechanism 11, and an edge trimming and cutting mechanism 13 and the winding mechanism 14, the front end of the conveyor belt conveying roller table is provided with a grid cloth lead-in roller 48, and a coating mechanism 5 is provided on the conveyer belt conveying roller table behind the mesh cloth lead-in roller 48, and a batching mechanism 5 is arranged above the coating mechanism 5. The device 4 and the conveying roller table behind the coating mechanism 2 are arranged in the drying mechanism 6 . The mesh cloth conveying mechanism includes a mesh cloth unwinding and rolling machine 1 , a mesh cloth joint platform 2 , and a mesh cloth deviation correcting and tensioning device 3 . Between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com