Anti-counterfeiting plastic packaging container

A technology for plastic packaging and containers, which is applied in packaging, packaging protection, and devices to prevent repeated filling of containers, and can solve problems such as harming the interests of businesses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

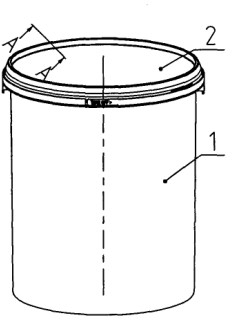

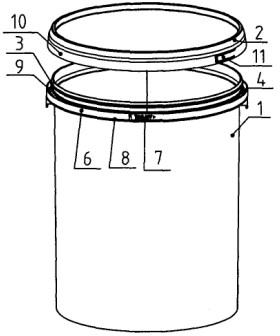

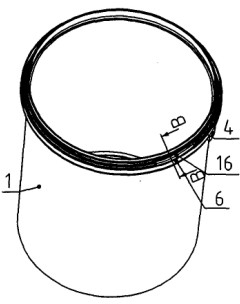

[0016] Such as Figure 1~4 , shown in 6, a kind of anti-counterfeiting plastic packaging container, it comprises staving 1 and bung 2, the outer side of the top of staving 1 is provided with the first clasp 3 of some protruding, and the inboard of bung 2 is provided with The inner convex second clasp 12 matched with the first clasp 3, the bottom of the bucket cover 2 is provided with a second tear ring 10, the second tear ring 10 is provided with a second tear opening 11, the second There is a second thin wall 13 between the tear ring 10 and the second clasp 12, and the barrel body 1 below the first clasp 3 is provided with a skirt 4 and a first tear ring 6 outside the skirt 4, The outer surface of the skirt 4 and the inner surface of the first tear ring 6 form a first groove 9 that can be inserted into the second tear ring 10, the first tear ring 6 is provided with a first tear opening 7, and the skirt Between the edge 4 and the first tear ring 6 there is a first thin wall 8...

Embodiment 2

[0018] Such as figure 1 , 2 , shown in 5 and 6, a kind of anti-counterfeit plastic packaging container, it comprises staving 1 and bung 2, is provided with the first clasp 3 of some protruding outwards on the outside of the top of staving 1, in the inner side of bung 2 An inwardly protruding second clasp 12 matched with the first clasp 3 is provided, and a second tearing ring 10 is provided on the bottom of the bucket cover 2, and a second tearing opening 11 is provided on the second tearing circle 10, There is a second thin wall 13 between the second tearing ring 10 and the second clasp 12, and the barrel body 1 below the first clasp 3 is provided with a skirt 4 and a first tearing circle positioned outside the skirt 4 6. The outer side of the skirt 4 and the inner side of the first tear ring 6 form a first groove 9 that can be inserted into the second tear ring 10, and the first tear ring 6 is provided with a first tear opening 7 , There is a first thin wall 8 between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com