Coking and coal blending method with participation of gas coal

A gas-coal and coal blending technology, which is applied in the field of coking coal blending in which gas-coal participates, can solve problems such as low blending amount, large coke lumpiness, and poor wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

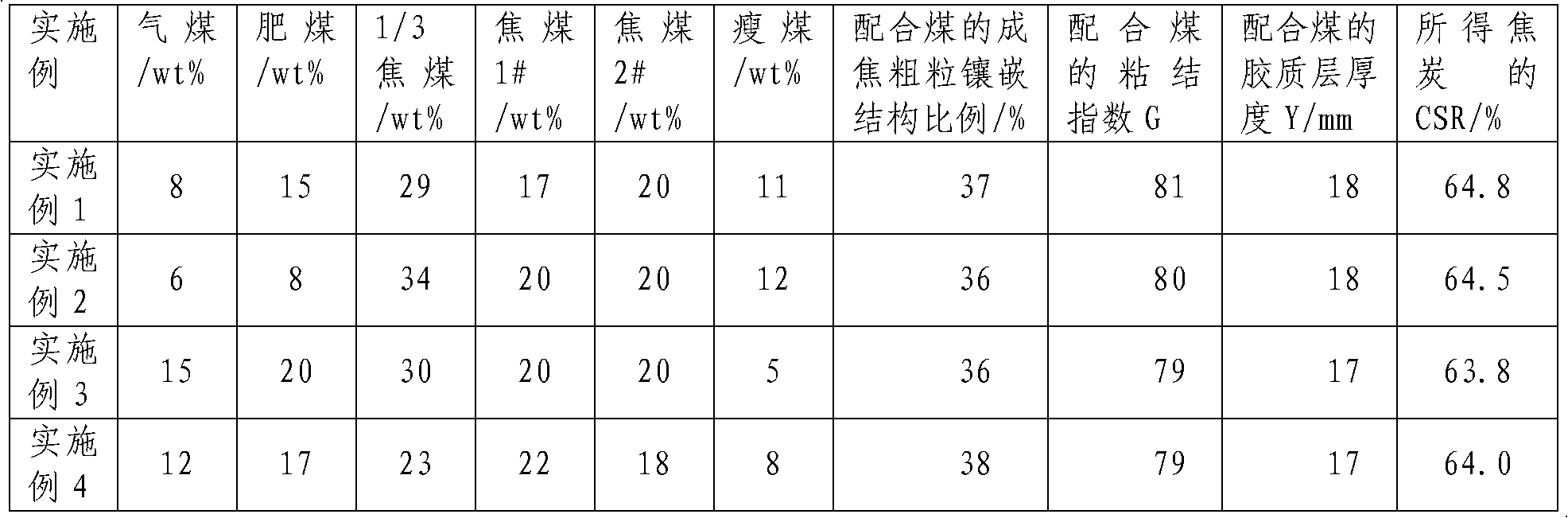

[0012] The present invention will be described in further detail below in conjunction with specific embodiments.

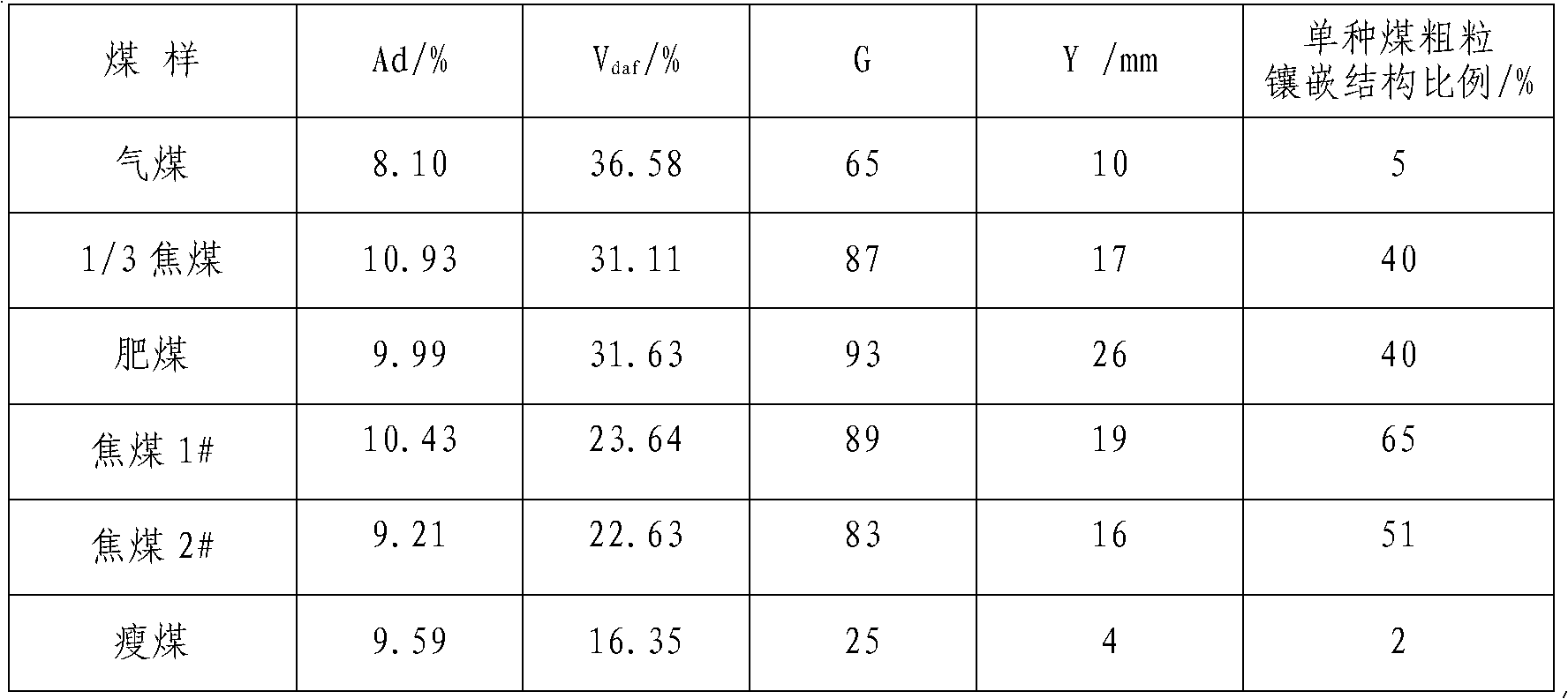

[0013] In the coking coal blending method involving gas coal of the present invention, the coking index G value of the gas coal is 50-70, the blending amount of the gas coal is 5-15 wt%, and the coal blending steps are as follows:

[0014] 1) 15-25wt% coking coal 1# is added, and the coking coal 1# has a coke-forming coarse-grain mosaic structure ratio of ≥60%;

[0015] 2) 5-20wt% of fat coal is added, the maximum Gigabit fluidity MF of the fat coal is more than 60000ddpm, the b value of the Oya expansion degree is more than 150%, and the proportion of coke coarse grain mosaic structure is more than 40%;

[0016] 3) Mix in 1 / 3 coking coal, coking coal 2# and lean coal, and make the proportion of coking coarse-grain mosaic structure of the mixed coal reach more than 35%, the bonding index G value is 79-82, and the colloidal layer thickness Y value is 17-19mm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com