Portable air compressor with wire winding function

An air compressor, portable technology, applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., can solve the problems of potential safety hazards, machine damage, leakage, etc., to eliminate potential safety hazards and prolong service life , Eliminate the effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

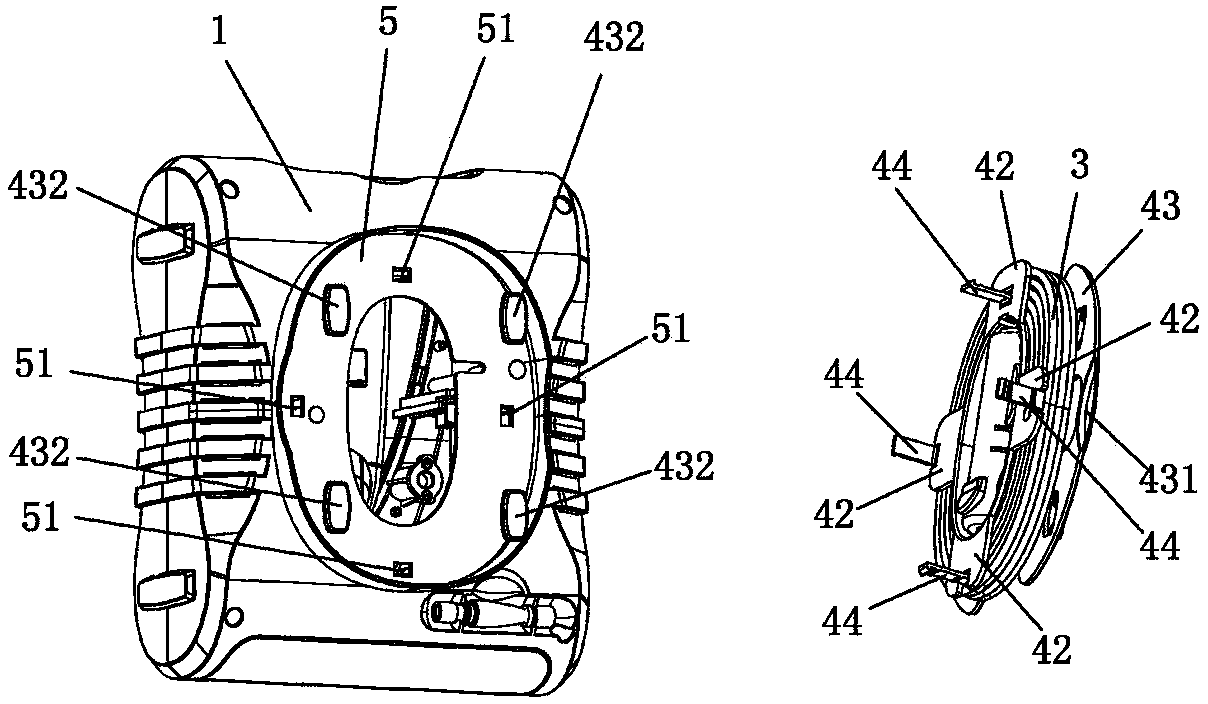

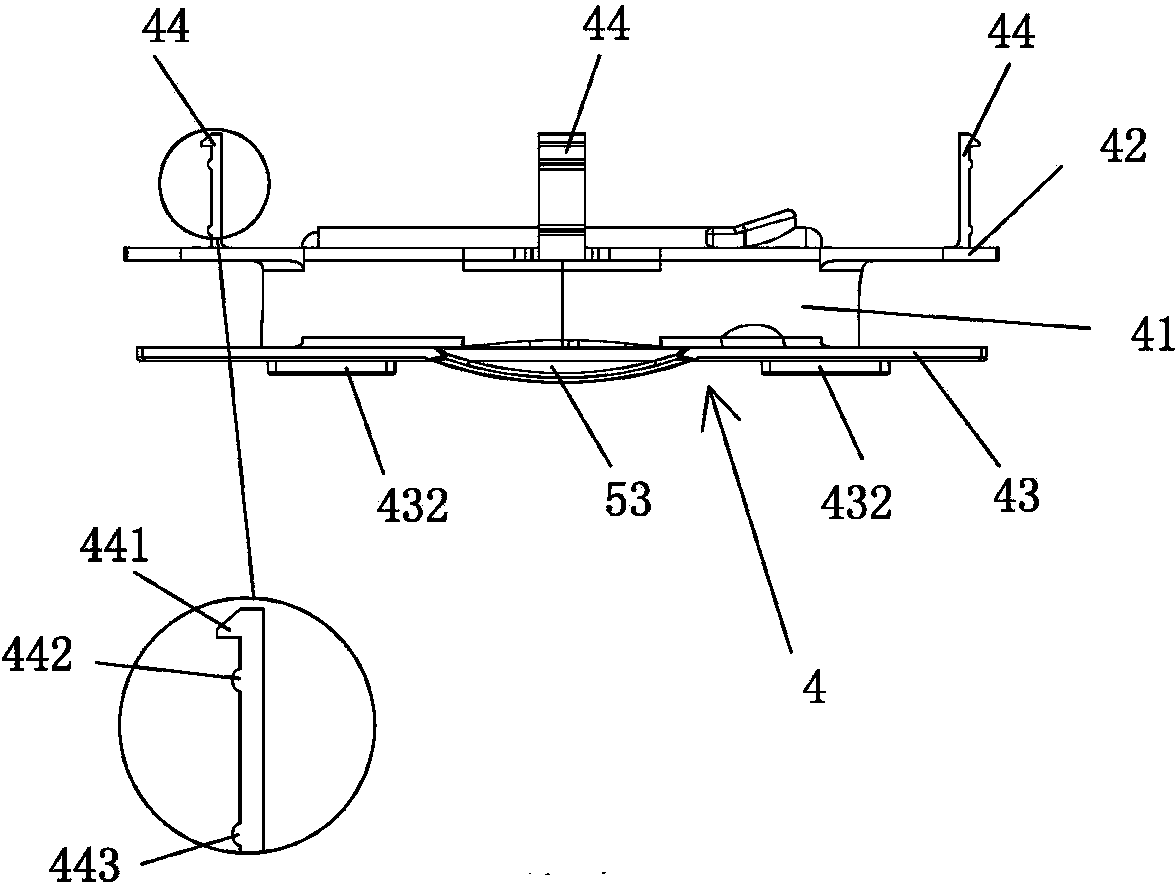

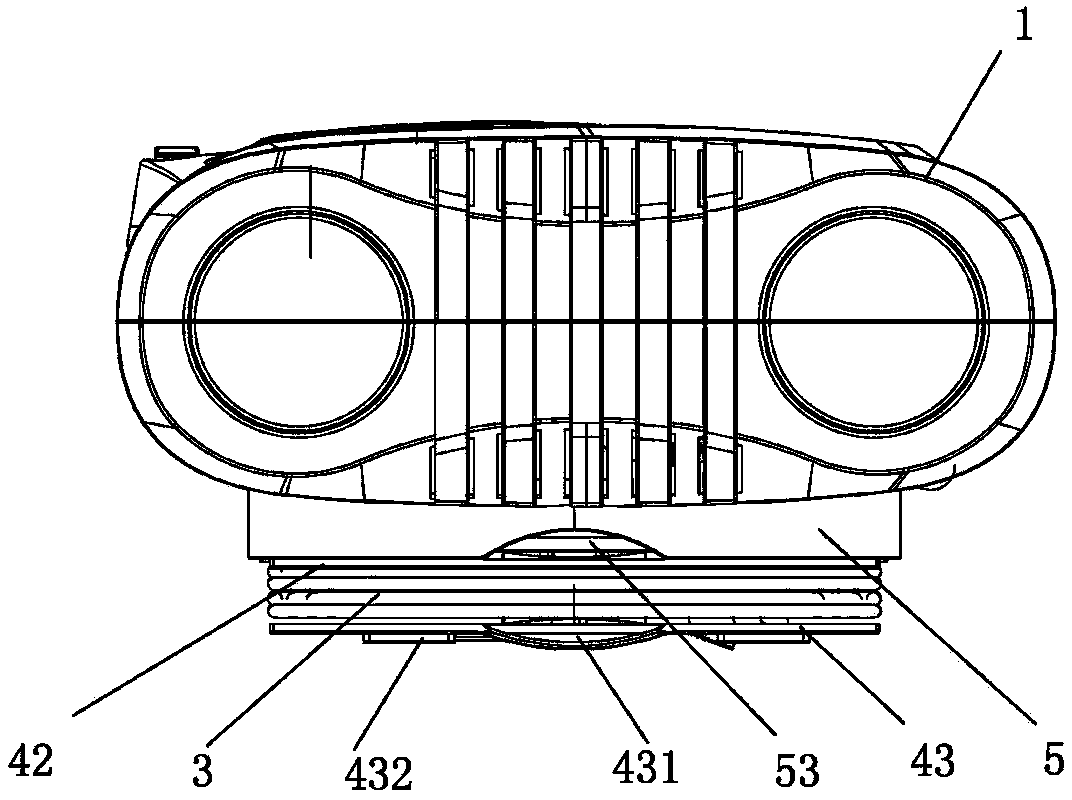

[0058] Embodiment 1 of a portable air compressor with a wire take-up function of the present invention, such as Figure 1 to Figure 5 As shown, it includes: a casing 1, an air compressor core 2, a wire take-up device 4 and a power cord 3; the bottom of the casing 1 is provided with a boss 5, and the boss 5 is provided with a clamping hole 51. The air compressor core 2 is arranged inside the casing 1 .

[0059] like image 3 , Figure 4 , Figure 5 As shown, the arrangement of the boss 5 increases the storage space inside the casing 1 , so that the core components such as the air compressor core 2 are not affected by the wire take-up device 4 .

[0060] like figure 1 , image 3 , Figure 5 As shown, the wire take-up device 4 is arranged at the bottom of the boss 5 , the wire take-up device 4 can be pulled out and pushed from the boss 5 through the corresponding cooperation with the clamping hole 51 , and the power cord 3 is wound around the wire take-up device 4 .

[00...

Embodiment 2

[0075] Embodiment 2 of a portable air compressor with a wire take-up function of the present invention, the main technical solution of this embodiment is the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1 , which will not be repeated here. The difference between this embodiment and Embodiment 1 is:

[0076] The number of the clamping feet 44 is set to one, and the clamping feet 44 are fixed to the center of the upper surface of the baffle plate 42 on the winding wire; .

[0077] When one clip 44 is used, the clip 44 can be appropriately set to be slightly thicker to prevent the clip 44 from being broken by excessive force. The structure of one clip 44 matching one clip hole 51 is simpler, material is saved, the mold is easy to manufacture, the cost is lower, and the production efficiency is higher.

[0078] like figure 1 , image 3 , Figure 4 As shown, the edge of the boss 5 is provided with a first recess ...

Embodiment 3

[0081] Embodiment 3 of a portable air compressor with a wire take-up function of the present invention, the main technical solution of this embodiment is the same as that of Embodiment 2, and the features not explained in this embodiment are explained in Embodiment 2 , which will not be repeated here. The difference between this embodiment and the second embodiment is that the number of the clamping feet 44 is set to two, and the two clamping feet 44 are arranged oppositely;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com