Optical axis fine tuning device and fine tuning method thereof

A technology of fine-tuning device and optical axis, applied in lighting device, lighting device parts, light source fixing and other directions, can solve the problems of affecting monitoring effect, the spot cannot illuminate the central position of the screen, etc., to achieve light weight, small repeatability error, Adjust the effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

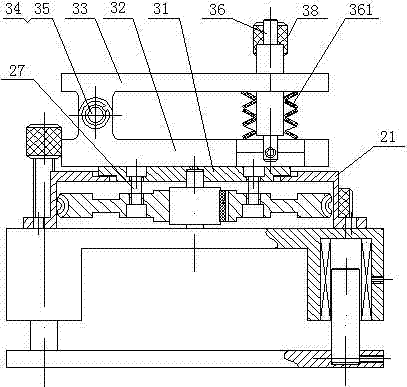

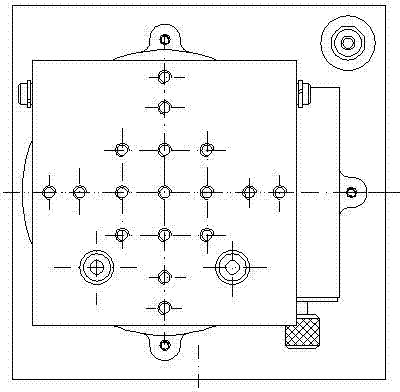

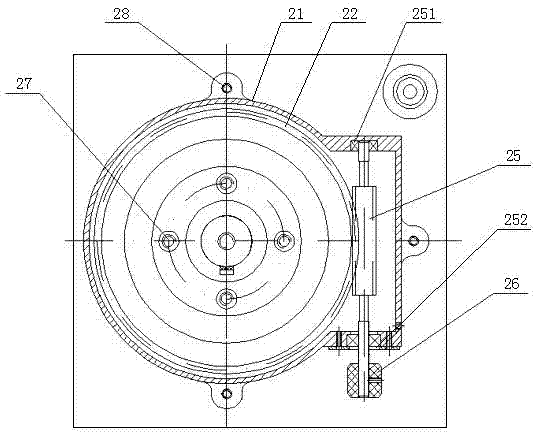

[0027] as attached figure 1 to attach Figure 4 Shown, the present invention is mainly made of base 11, cylindrical guide rail 12, linear motion rolling bearing 13, middle support body 14 and height adjustment screw 16 by complete machine height adjustment mechanism 1. The lower part of the cylindrical guide rail 12 is fixedly connected on the base 11 by set screws 111, and the upper part of the cylindrical guide rail 12 is movably connected with the linear motion rolling bearing 13 in the rolling bearing shaft hole 15 fixed on the middle supporting body 14, and It can move up and down, and the support top screw 131 fixes the linear motion rolling support 13 on the middle support body 14; its height adjustment screw 16 is rotationally connected with the base 11: the lower end of the height adjustment screw 16 is equipped with a screw deep Groove ball bearing 161, and it is fixed in the bearing housing hole of base 11 by lead screw fastening screw 112; In the transmission str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com