Drying system for lithium ion battery cores

A technology of lithium-ion battery and drying system, applied in the improvement field of baking equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

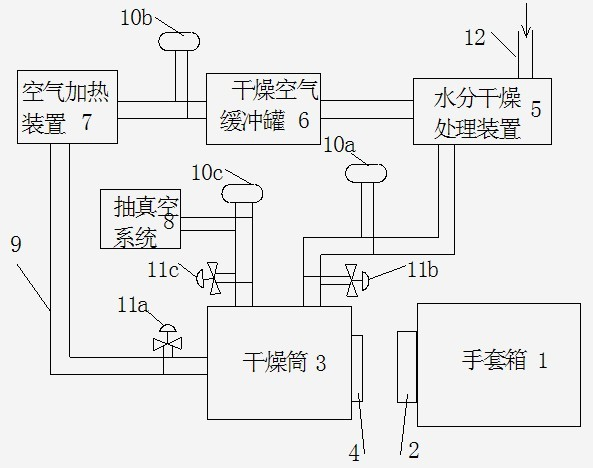

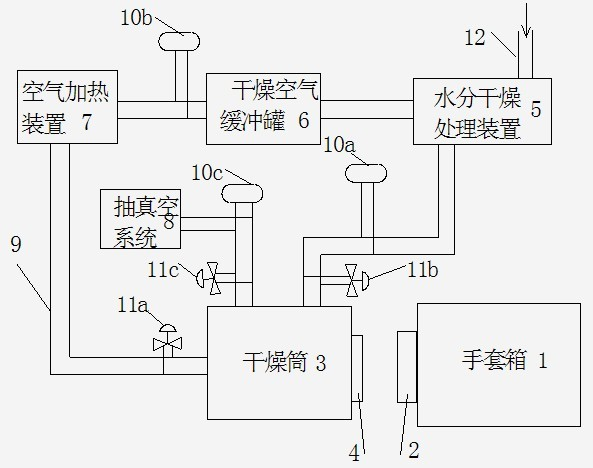

[0028] This embodiment includes a drying cylinder 3, which is detachably connected to the pipeline. After the drying of the cells in the drying cylinder is completed, the movable drying cylinder is docked with the glove box for the next liquid injection operation.

[0029] In order to realize seamless docking, a barrel cover 4 is provided on one side of the drying cylinder 3, and a sealing ring is also provided on the barrel cover. The side of the glove box 1 that can be docked with it is provided with a protruding transition chamber 2, and the transition chamber 2 is connected to the barrel. The cover 4 is engaged to realize the seamless connection between the drying cylinder 3 and the glove box 1 .

[0030] When the system of the present invention was working, the compressed air input pipeline 12 delivered to the system from the outside entered the moisture drying treatment device 5, and the moisture present in the external compressed air was dried and processed in the moist...

Embodiment 2

[0041] The above-mentioned embodiments only express the implementation manner of the present invention, and the description thereof is relatively specific and detailed, but should not be construed as limiting the patent scope of the present invention. It should be pointed out that for those skilled in the art, without departing from the concept of the present invention, several modifications and improvements can be made, such as selection changes of the transmission modulation processing circuit and the reception processing circuit, etc., all of which are Belong to the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com