Device for preparing magnesium alloy semi-solid slurry by gas stirring

A semi-solid slurry and gas stirring technology, applied in stirring devices, lighting and heating equipment, furnace components, etc., can solve the problems of general quality of semi-solid slurry, high energy consumption by stirring method, and difficulty in large-scale preparation. The effect of great popularization and application value, compact and reasonable device structure, and rapid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment provides detailed implementation methods and specific operating procedures on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments. .

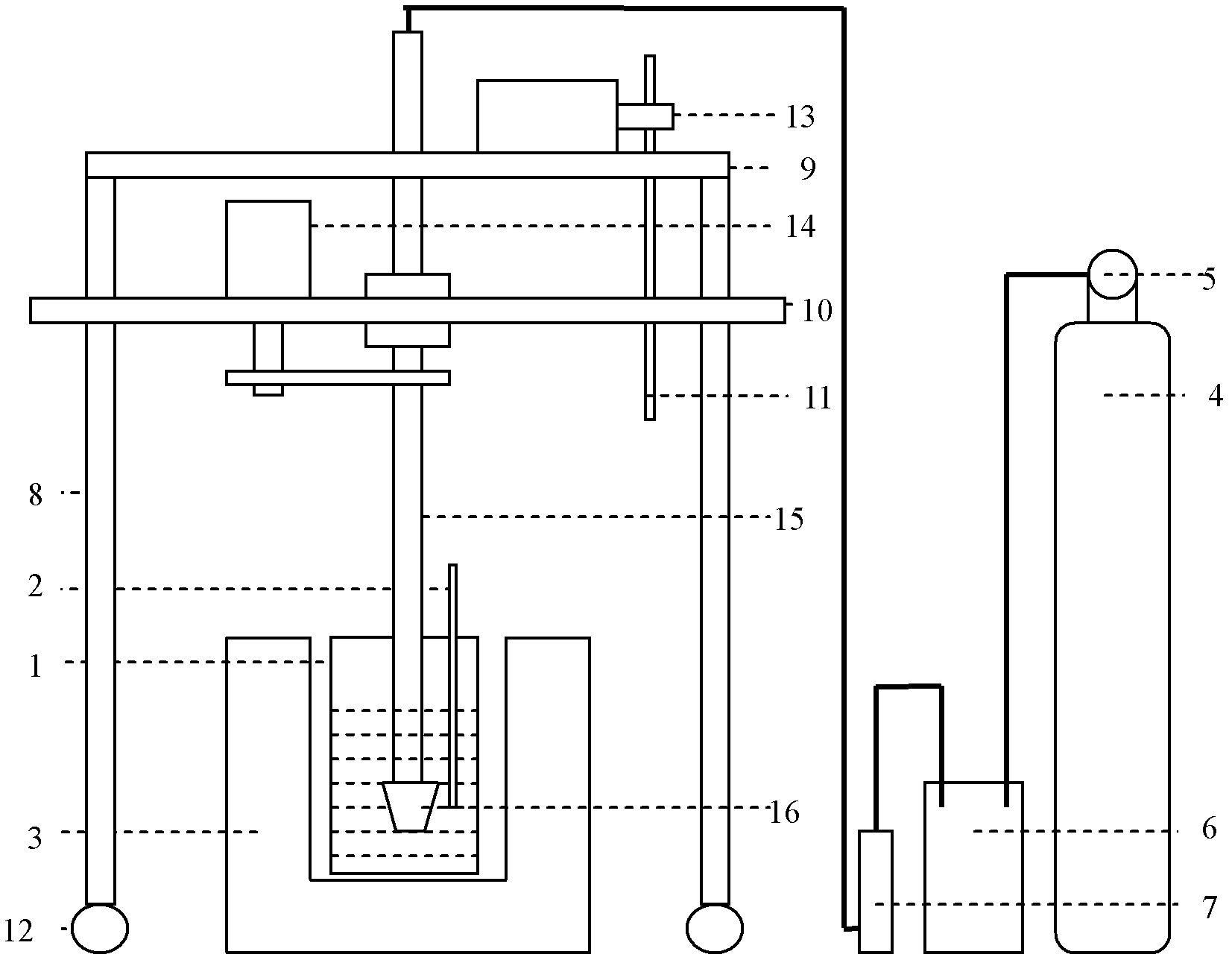

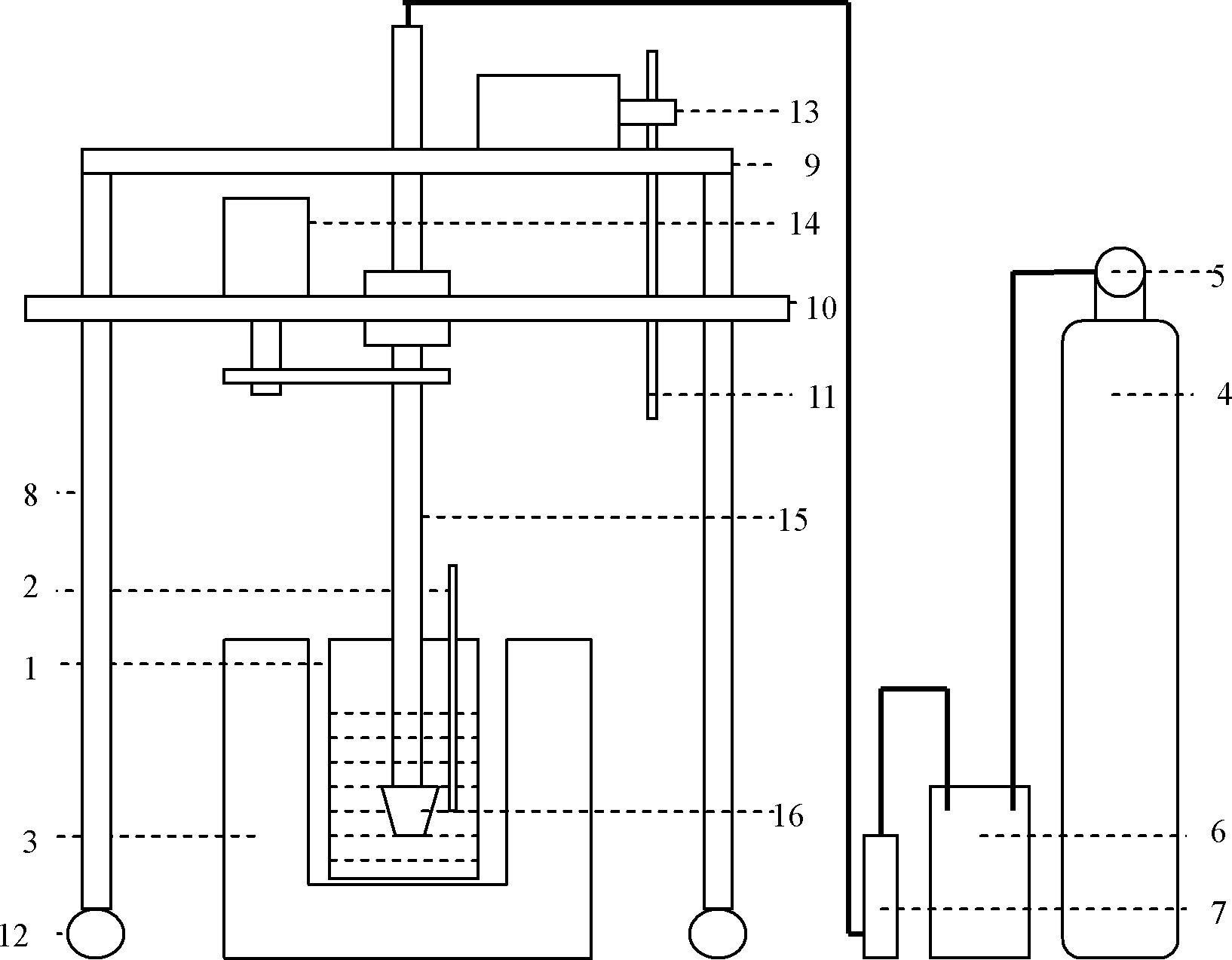

[0015] like figure 1 As shown, this embodiment includes a heating and holding device, a stirring gas input device and a stirring device, wherein the heating and holding device accommodates and heats the magnesium alloy melt, the stirring gas input device is connected to the stirring device, and the stirring gas is fed from the stirring gas input device After the output, it is input into the stirring device through the hose. The stirring device is located directly above the heating and heat preservation device, and extends into the heating and heat preservation device to penetrate into the melt.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com