Dynamic balance testing method for rotatable part

A technology of rotating parts and testing methods, which is applied in the field of mechanics, can solve problems such as inconsistencies in states, and achieve the effects of improving accuracy, improving measurement accuracy, improving measurement accuracy and trimming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

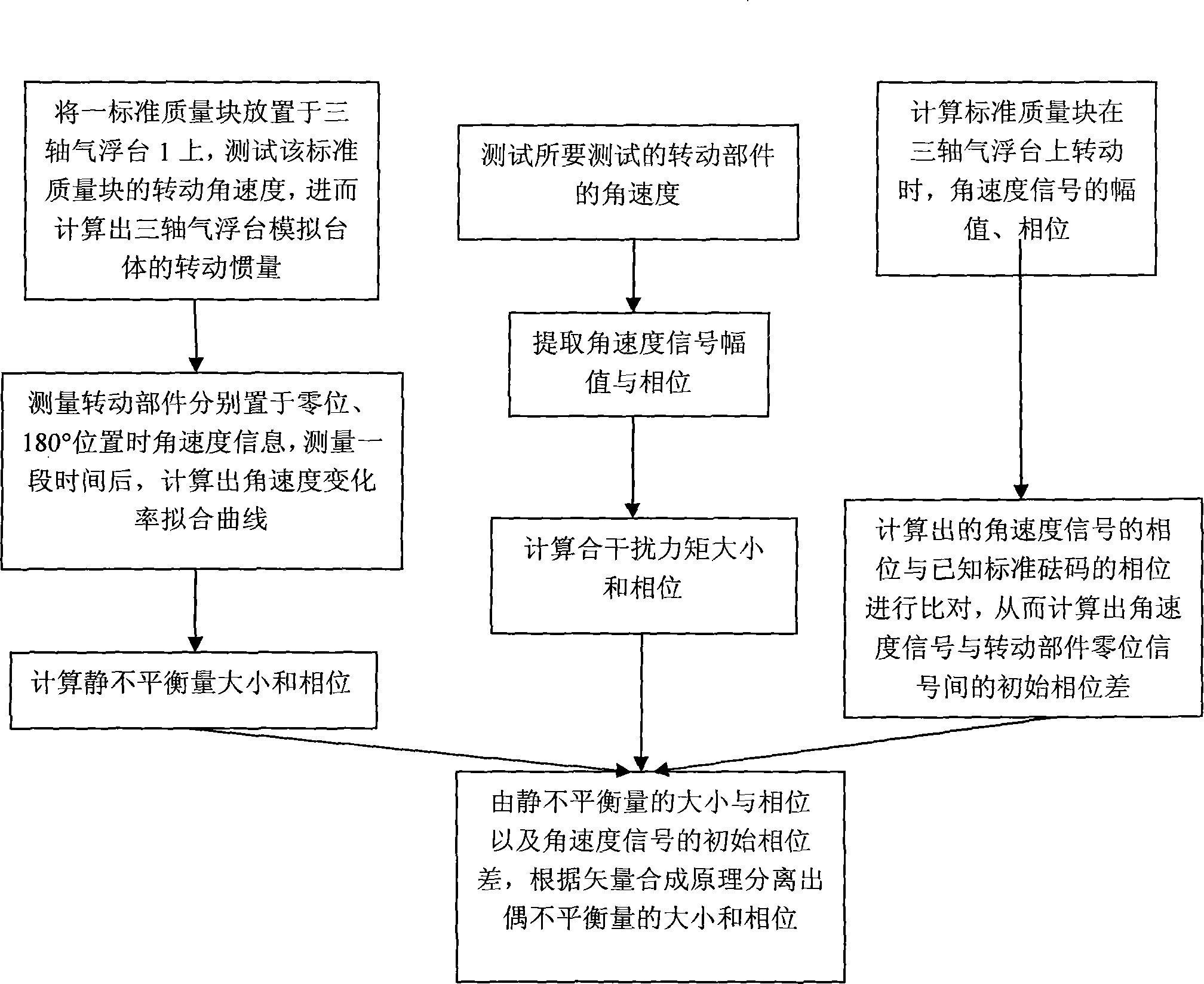

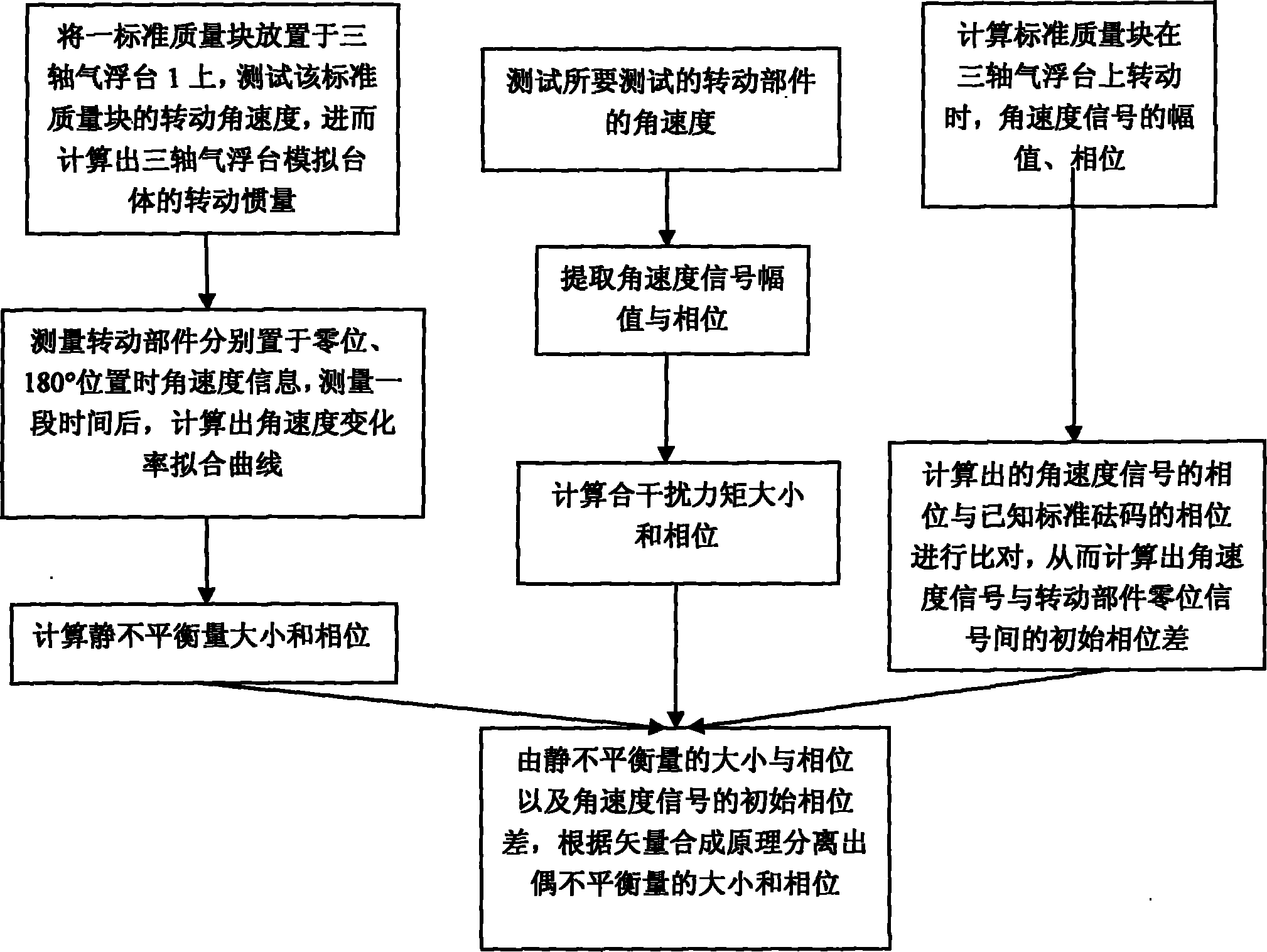

[0027] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0028] Before describing the method of the present invention, the test device to be used in the present invention will be described first.

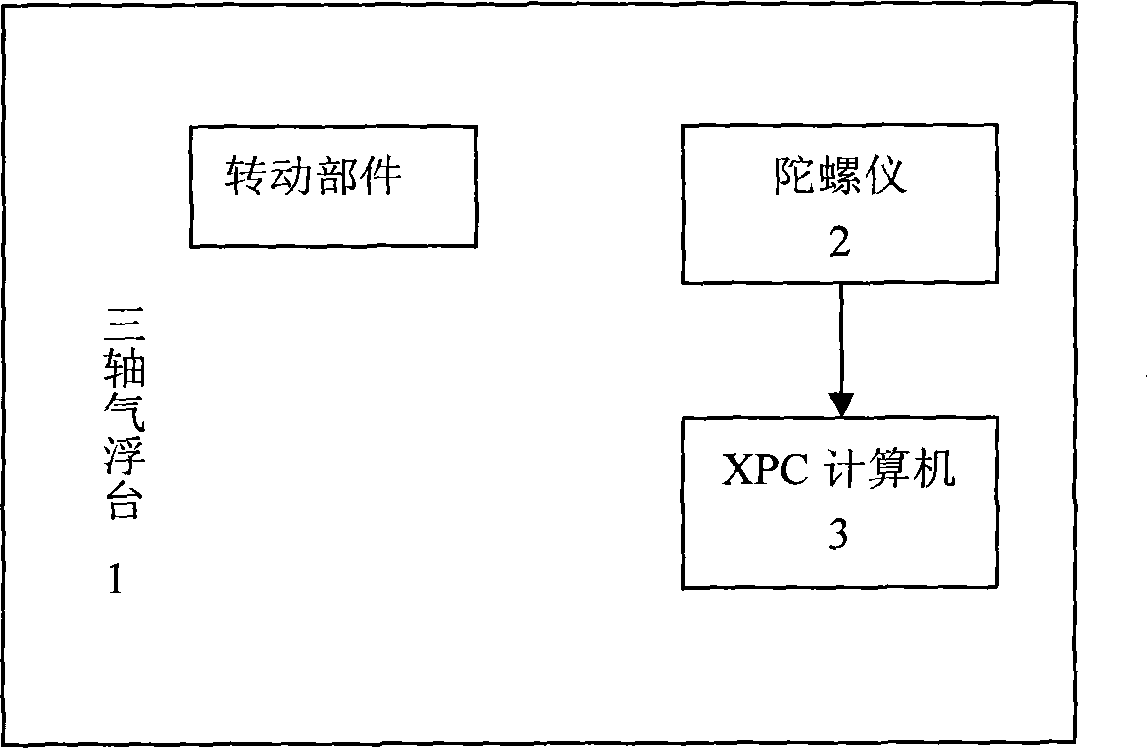

[0029] Such as figure 1 As shown, the testing device to be used in the present invention includes a three-axis air bearing table 1 , a gyroscope 2 and an XPC computer 3 . Wherein, the three-axis air bearing platform 1 selects a spherical air bearing to support the simulated platform body to realize microgravity within a certain angle range and the simulation of the free rotation environment in the directions of X, Y, and Z axes; the gyroscope Installed on the three-axis air bearing platform 1, it is used to measure the rotational angular velocity of the three-axis air bearing platform; the XPC computer 3 collects the angular velocity signal measured by the gyroscope 2 in real time, and eliminates the measurement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com