Brightness enhancement film and manufacturing mold and manufacturing method thereof

A technology of brightening film and optical surface, applied in diffusing elements, prisms, etc., can solve the problems of inability to solve the problem of bad brightness enhancement film at the same time, affecting the display quality of liquid crystal display, scratching of sharp edges and corners of prism structure, etc., to reduce the Newton ring. and moiré phenomenon, assembly process advantages, the effect of mitigating moiré phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

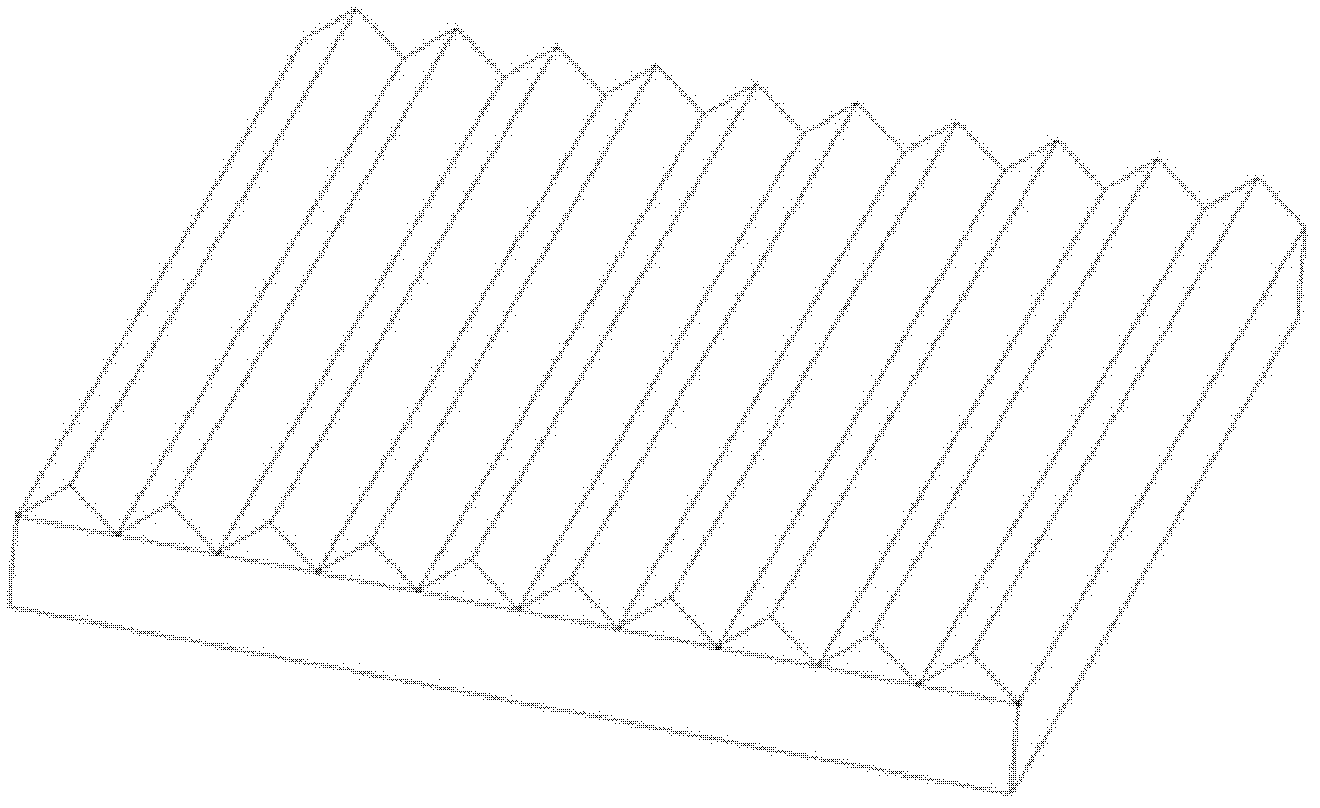

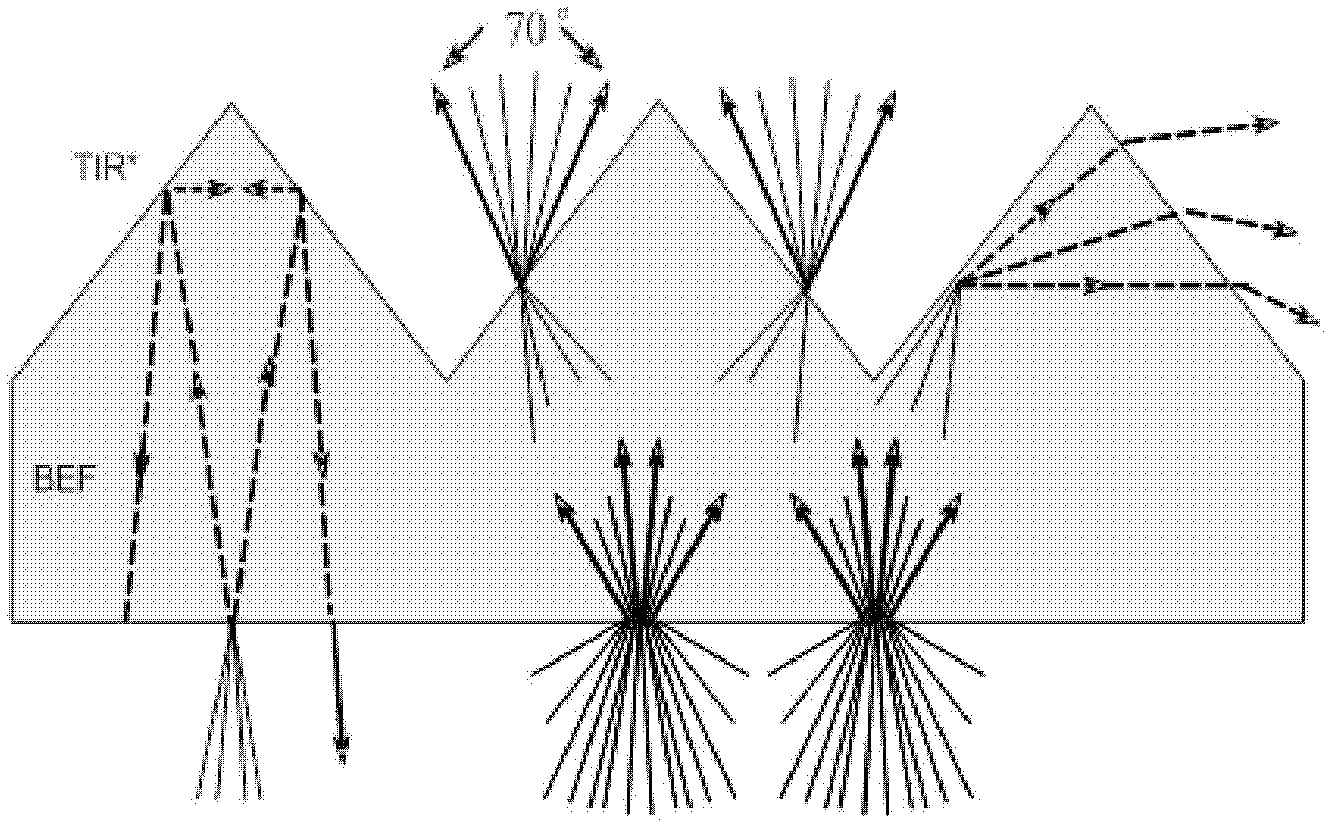

[0061] Such as Figure 4 As shown, the brightness enhancement film includes a substrate 102 and a prism structure layer 108 thereon. The substrate 102 has a first optical surface 106 and a second optical surface 104 located on the first optical facing surface. A prism structure layer 108 is arranged on the first optical surface 106, and the prism structure layer 108 includes several first prism structure units 112A and several second prism structure units 112B, wherein, in the prism arrangement direction 110A, every eighth A prism structure unit 112A is provided with a second prism structure unit 112B regularly arranged in a prism structure array, each prism structure unit stretches and extends along the prism stretching direction 110B, and the several prism structure units are continuously curved in the stretching direction 110B The curve determined by the locus curve trigonometric function equation Y=5sin(0.2X)(μm), that is, the curved trajectories of any two adjacent curve...

no. 2 example

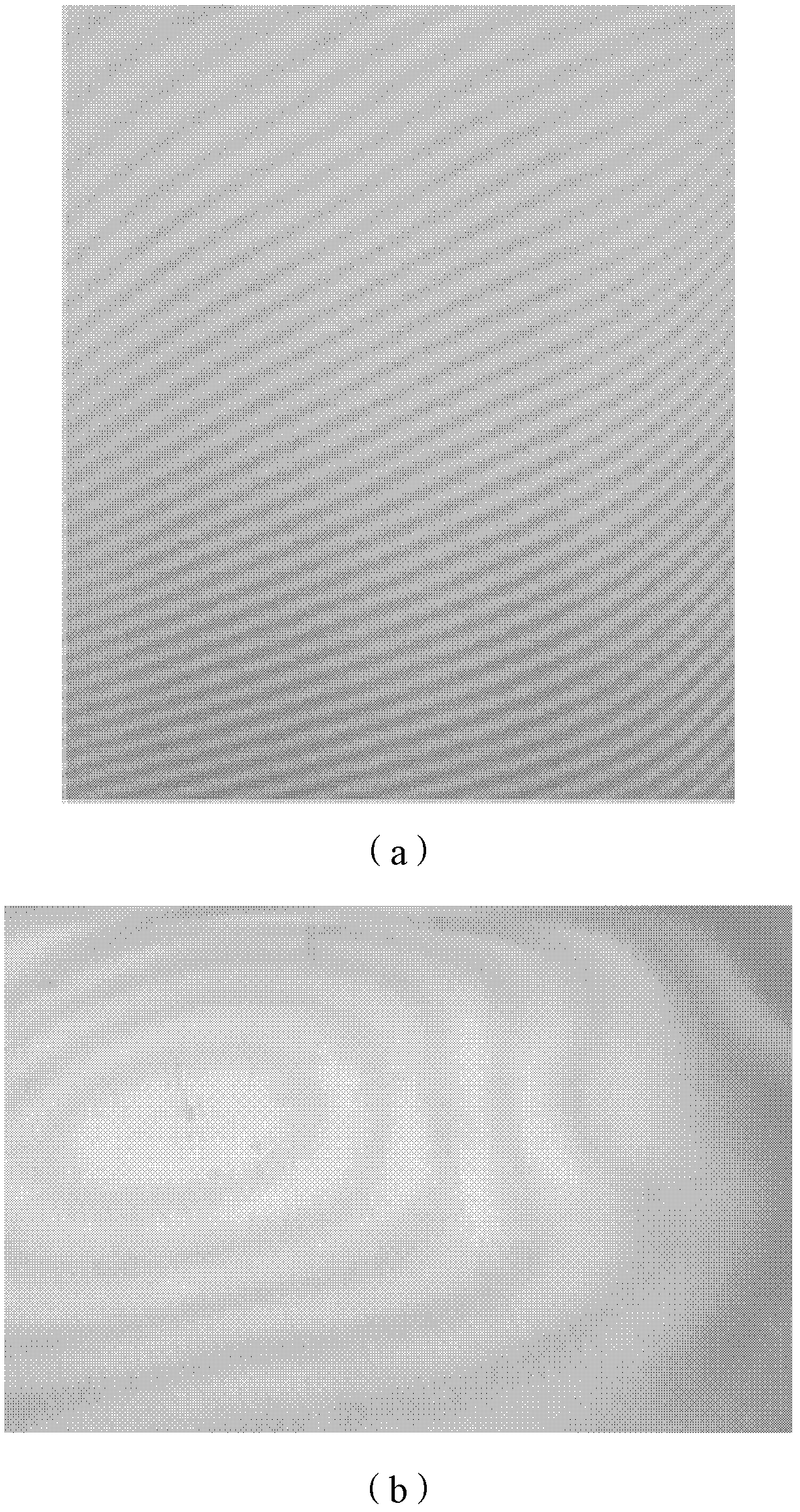

[0071] Although the first embodiment can realize diffusion and anti-scratch functions at the same time, and reduce the effects of negative optical effects such as Newton rings and moiré patterns, since the prism structural units are arranged regularly, it is necessary to make further improvements to create more Conditions for suppressing moiré well.

[0072] Such as Figure 9 As shown, the prism structure enhancement film includes a substrate 202 and a prism structure layer 208 thereon. The substrate 202 has a first optical surface 206 and a second optical surface 204 located on the first optical facing surface. A prism structure layer 208 is arranged on the first optical surface 206, and the prism structure layer 208 includes a plurality of first prism structure units 212A and a plurality of second prism structure units 212B, and each prism structure unit extends and extends along the prism extension direction 210B. , the plurality of prism structural units are curves deter...

no. 3 example

[0082] For the second embodiment, although the irregular arrangement of the prism structural units can better realize the diffusion and anti-scratch functions at the same time, and reduce the effects of negative optical effects such as Newton rings and moiré patterns, but because the adjacent first prism structural units 212A and the second prism structure unit 212B are still the same curved trajectory curve, with regularity, if the curved trajectory of the adjacent prism structure is further set to be different, then the film of this kind of brightness enhancement film and regular structure or When the liquid crystal layer is used together, the conditions for moiré patterns can be completely eliminated.

[0083] Such as Figure 13 As shown, the prism structure enhancement film includes a substrate 302 and a prism structure layer 308 . The substrate 302 has a first optical surface 306 and a second optical surface 304 located on the first optical facing surface. A prism struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com